LV800AW-TT Vertical Turning Center for AL Wheel Cutting

The Turning Center LV800AW-TT, designed by Hyundai WIA with years of expertise and the latest technology, is the best performing machine in the AL Wheel automation line.

Aluminum Wheel machining with high speed, high rigidity and productivity

- Max. aluminum wheel processing capacity (21.5")

- 2-turret, high-speed aluminum wheel processing machine

- ACC servo motor-based speed control and minimization of shock at shutdown

- Optimum machine structure for automation

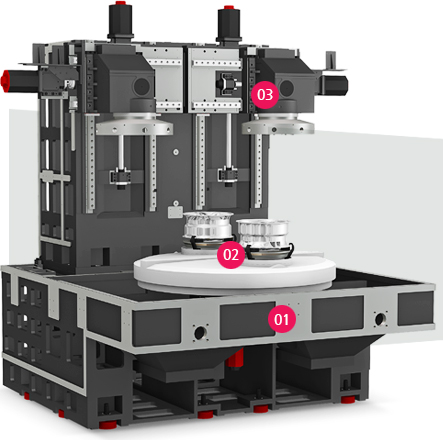

Basic Features

Powerful Cutting Capability, 22inch AL Wheel Cutting 2 Turret CNC Vertical Turning Center

1Bed and Chip Disposal

For smooth chip disposal, the size of chip outlet on the bed is enlarged to 350mm(13.8″) by 856mm(33.7″) and installed with the steep angle of 45 degrees so that it can easily handle a large amount of chips.

Reduction of non-cutting time by fast rapid speed

Rapid Traverse Rate

(X/Z axis) |

30/30 m/min

(1,181/1,181 ipm) |

| Travel (X/Z axis) |

420/650 mm (16.5″/25.6″) |

| Max. Wheel Size |

22.5″ |

| Max. Turning Dia. |

Ø650 (25.6″) |

| Max. Turning Height |

350 mm (13.8″) |

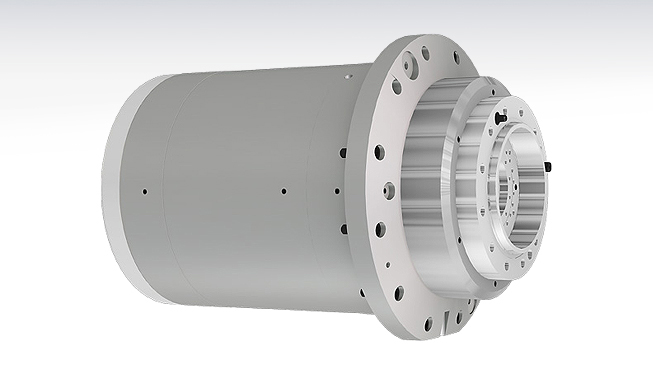

High-Precision Spindle

Long Lasting High Accuracy & Excellent Performance Vertical Turning Center

2Built-In Spindle

For best quality products, built-in spindle minimizes vibration and heat and provides fast acc/deceleration.

| SP. Speed |

3,000 rpm |

| SP. Motor |

55 kW (73.8 HP) |

| SP. Torque |

495 N.m (365 lbf.ft) |

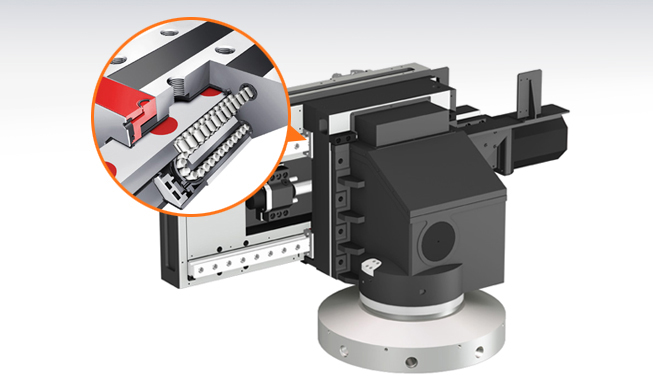

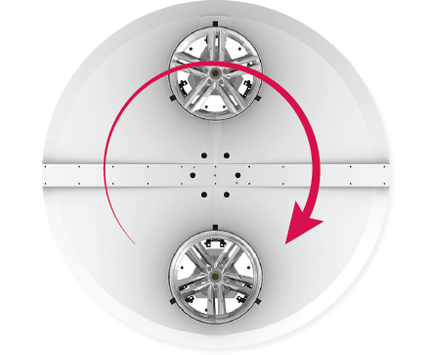

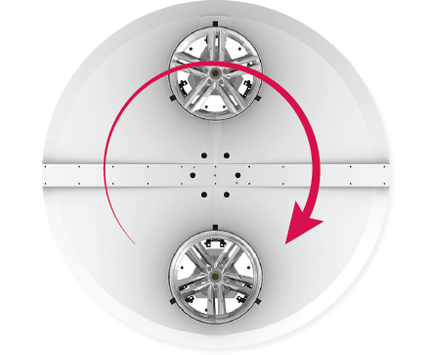

ACC (Automatic Chuck Changer)

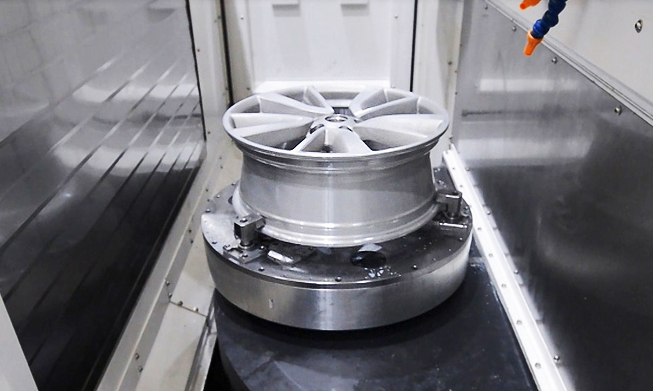

LV800AW-TT has the automatic chuck changer with high-speed 180-degree index rotation. This improves productivity since inner and outer side of the wheel can be processed at one machine.

Smooth operation of ACC is possible since it is driven by servo motor that allows for speed control which cannot be done with the ydraulic system. Also, the simple structure of ACC minimizes potential fault causes of electrical devices.

Special Chuck

Finger chuck provides stable and precise processing ability of aluminum wheel under at high speeds.

Max. Wheel Size : 22.5″

3Roller Type LM Guideway

Each travel axis is designed with highly rigid roller type LM guideway which enables a rapid traverse rate of 30m/min(1,181ipm). The ball screw has a diameter of 40mm(1.6″) and produces powerful thrust for heavy duty cutting.

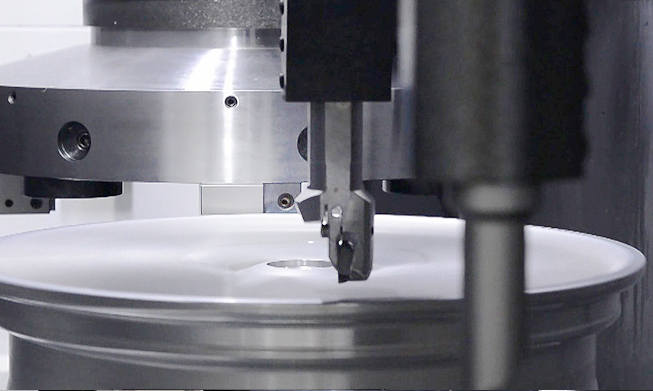

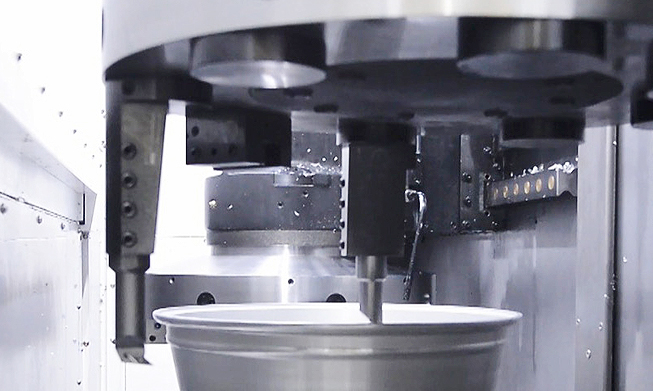

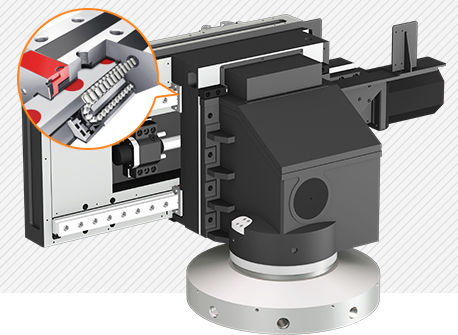

VDI 2 Turret

LV800AW-TT is designed with 2 turrets. Machining inner and outer surfaces of the wheel can be done simultaneously, reducing the machining time by 20% compared to that of 1-turret machine.

| Tool Size (OD/ID) |

□25x25/Ø40 rpm / Ø40 mm (1.6″) |

| Turret Type |

VDI50 (8 Angle 2 Turret) |

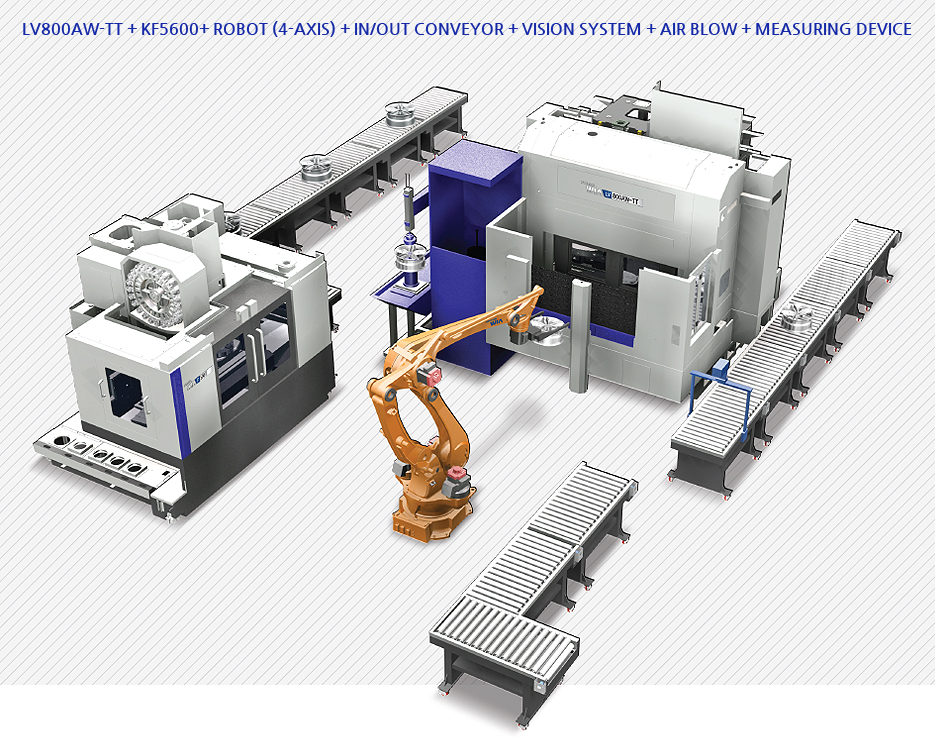

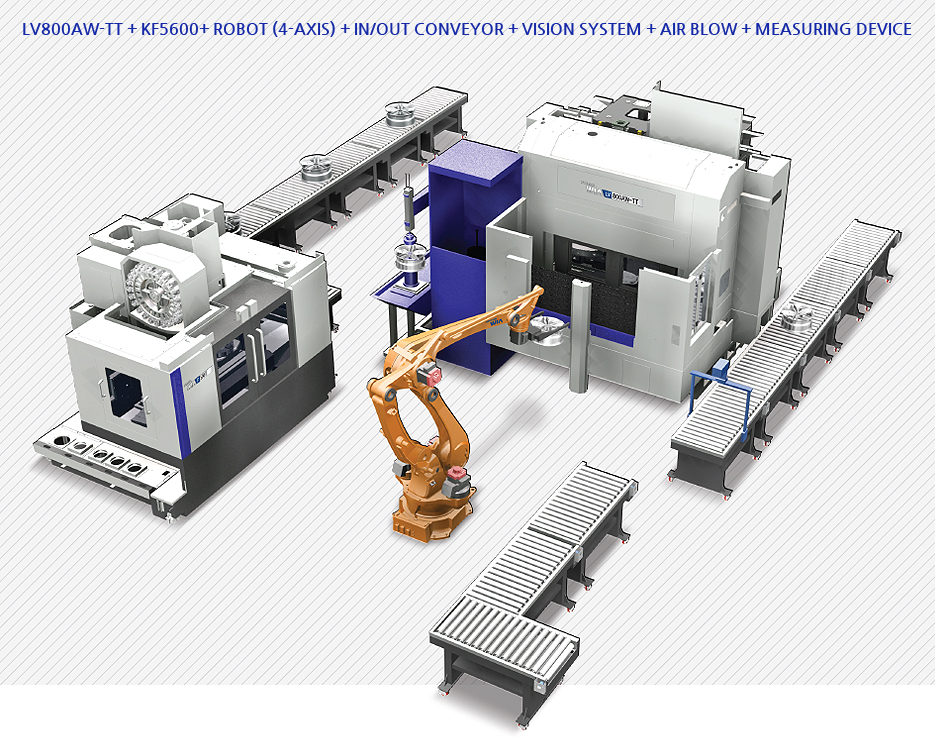

Automation System OPTION

Various Devices for User Convenience

Automation Consists

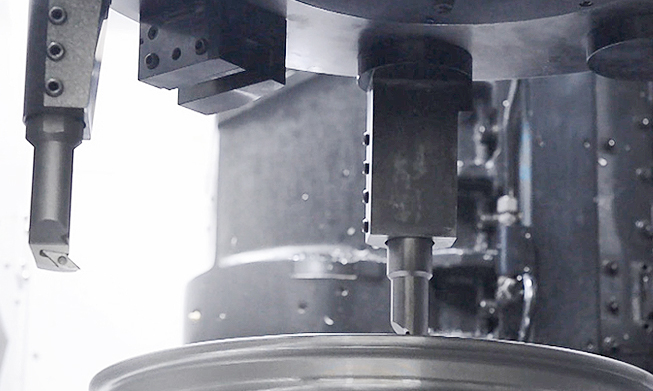

Machining Capability

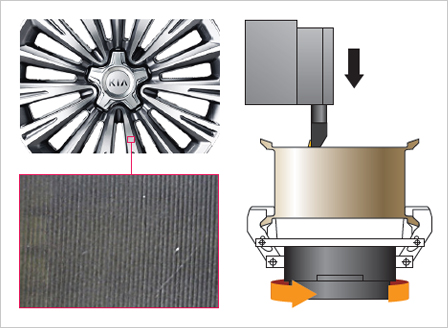

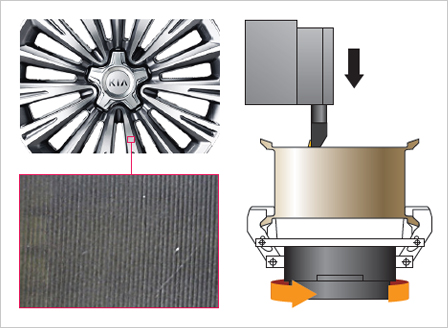

Surface Roughness

LV800AW-TT Cutting Test

| Work |

19×7J (Ø487.4×178) |

| Speed |

1,800 r/min |

| Traverse |

Max. 0.7mm/rev |

| Cutting Depth |

Max. 3.0mm |

| Coolant |

Density 6% |

| Cutting time |

119 sec |

Contour/Glossiness/I.D•O.D Maching : Fine