New Product

XF2000 5-Axis Machining Center for Impeller Machining

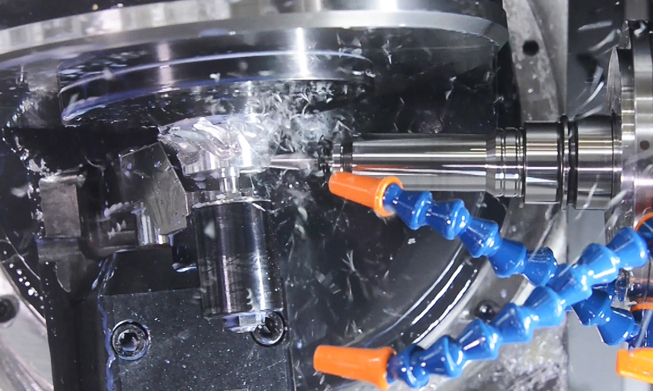

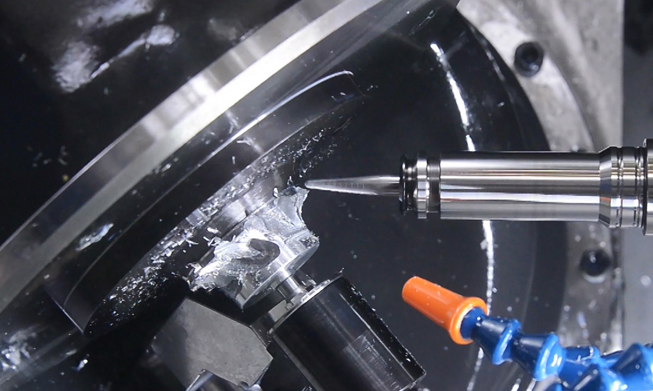

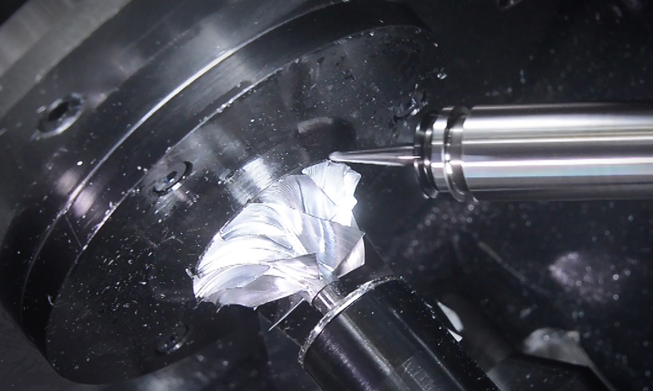

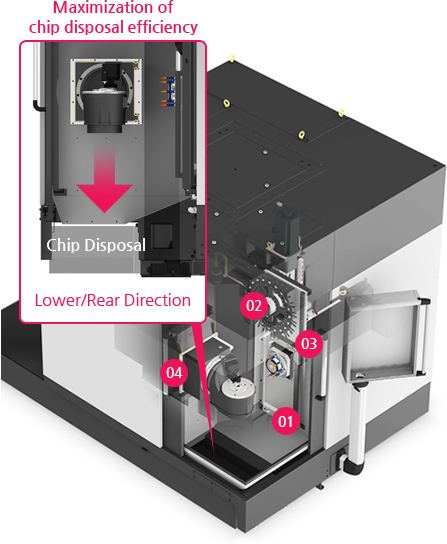

The XF2000, a high-speed / high-precision compact 5-axis simultaneous machining tool developed by HYUNDAI WIA German Research Center, has an optimal structure for productivity. The XF2000 is composed of an integrated column and cantilever-type table for improvement of maintenance and user convenience. In addition, we will provide our customers with remarkable productivity at the 2G of acceleration / deceleration of our highest level.

High-speed & High-precision

Compact 5-Axis Machining Center

- One-piece bed & column structure to increase structural stability

- World class acceleration and deceleration speed of 2G

- Linear and rotary scale as standard features for the high quality of machining

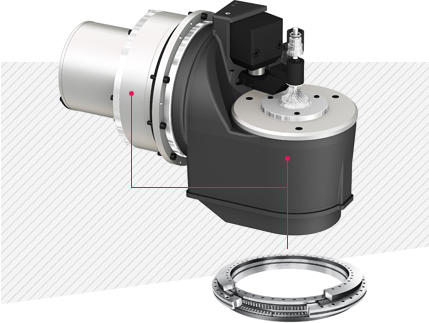

- Cantilever type DDM table

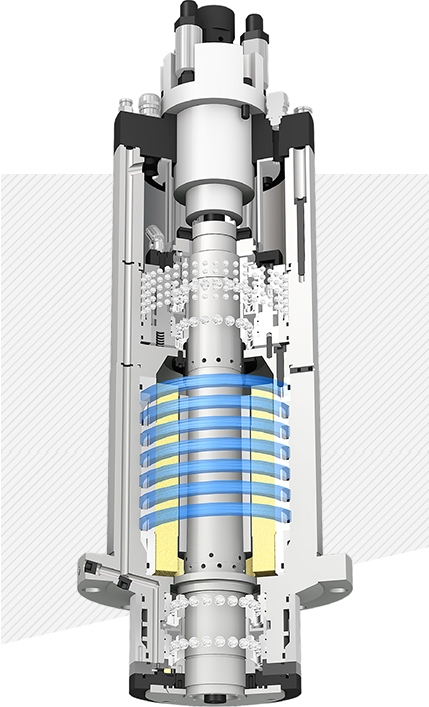

- 40,000rpm high-speed built-in spindle

- Spindle cooling device ensures stable machining capability even during the long work

Basic Features

High-Speed / High-Precision Compact 5-axis Simultaneous Machining Center for Impeller Cutting

Excellent Performance & High Accuracy Cutting

| Travel (X/Y/Z axis) | 300/300/200 mm (11.8″/11.8″/7.9″) |

| Rapid Traverse Rate (X/Y/Z axis) | 50/50/50 m/min (1,969/1,969/1,969) ipm |

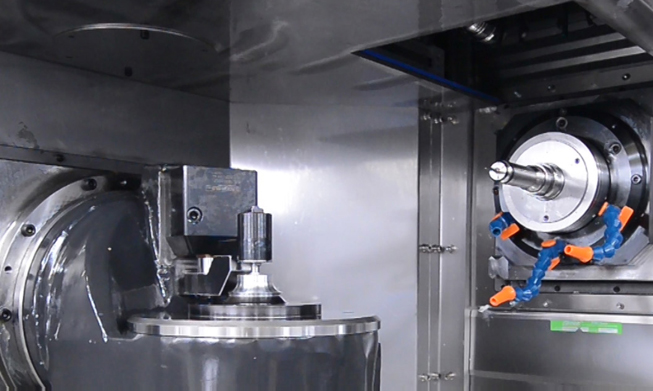

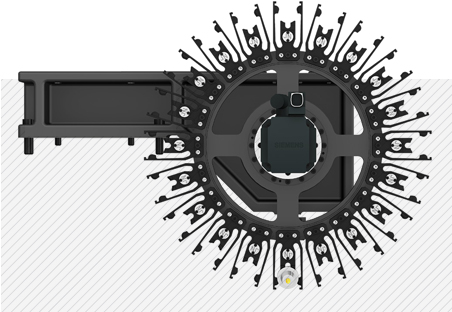

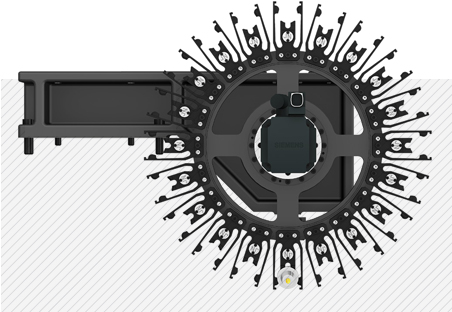

2ATC & Magazine

Developed as a pickup-type magazine with a relatively simple structure, automatic tool loading device is unnecessary, which is excellent in maintenance.

| No. of Tools | 20 EA |

| Tool Change Time (C-C) | 4.5 sec |

| Max. Tool Diameter | Ø50 (Ø2″) |

| Max. Tool Length | 200 mm (7.9″) |

| Max. Tool Weight | 1.5 kg (33 lb) |

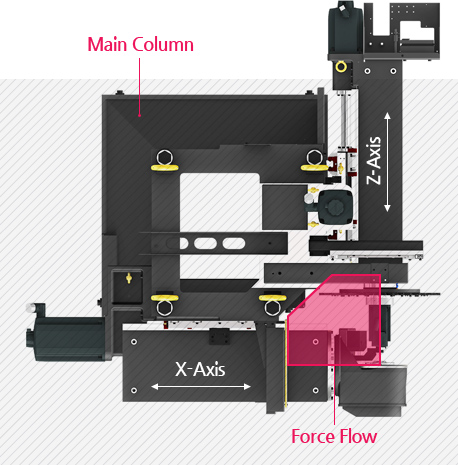

1One-piece Bed & Column

The XF2000 maximizes the dynamic rigidity by designing bed and column as an integral type, and improves the structural stability by concentrating the flow force between the work space and the tool.

Linear Scale (Std.)

Applied linear scale as a standard for high-precision mahining through the compensation of thermal displacement.

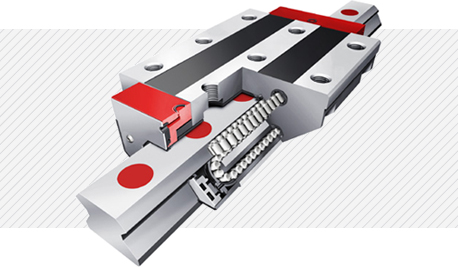

High Speed Roller LM Guideway

Roller LM guide with high acc./deceleration and rigidity has applied to reduce non-cutting time.

| Acc./Deceleration Speed (X/Y/Z axis) | 2G/2G/2G |

2ATC & Magazine

Developed as a pickup-type magazine with a relatively simple structure, automatic tool loading device is unnecessary, which is excellent in maintenance.

| No. of Tools | 20 EA |

| Tool Change Time (C-C) | 4.5 sec |

| Max. Tool Diameter | Ø50 (Ø2″) |

| Max. Tool Length | 200 mm (7.9″) |

| Max. Tool Weight | 1.5 kg (33 lb) |