New Product

Hi-MOLD6500 Vertical Machining Center for Mold Machining

The Vertical Machining Center Hi-MOLD6500 by Huyndai WIA CORP, the national (Kor) machine tool builder with years of expertise and the latest technology, are high-performance equipment for processing high quality molds.

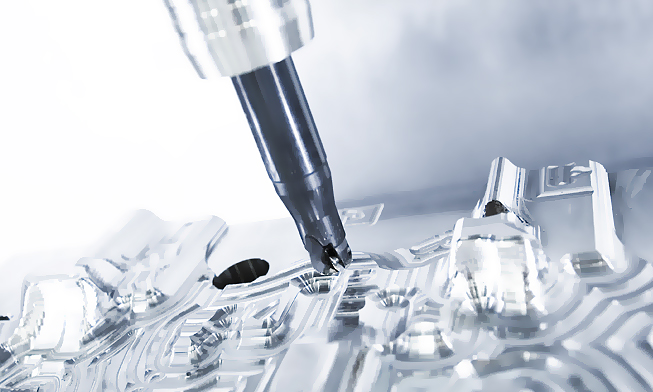

State-of-the-art Technology for

Machining Precision Molds

- Wall type machining center for utmost quality of molding

- High-precision spindle design with precision angular contact bearing

- 20,000 rpm built-in spindle for high-precision molding (Option : 24,000 rpm)

- Ball screw nut cooling system in all axes as standard

- Hyundai-Wia molding package for optimal mold parts tooling

Basic FeaturesSuper Quality & Productivity Vertical Machining Center for Mold Machining

Rapid Feed Rate (X/Y/Z axis)

- 40/40/40 m/min

Feed Travel (X/Y/Z axis)

- 1,100/650/550 mm

Table Size (LxW)

- 1,200x650 mm

Table Max. Load Capacity

- 1,000 kg (2,205 lb)

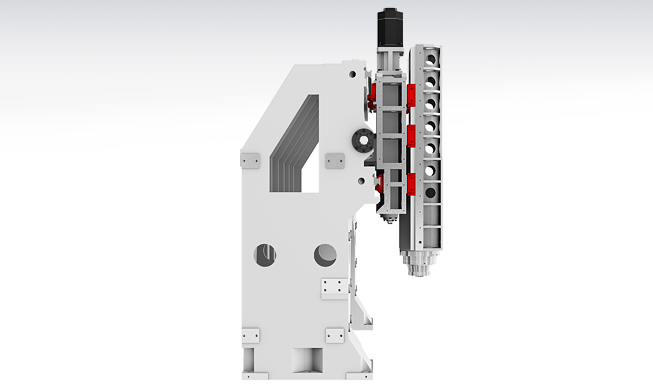

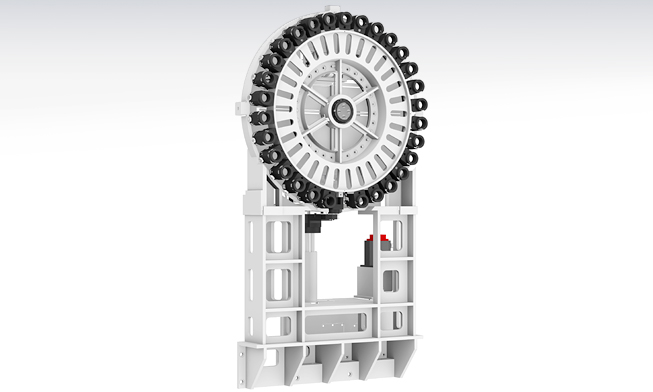

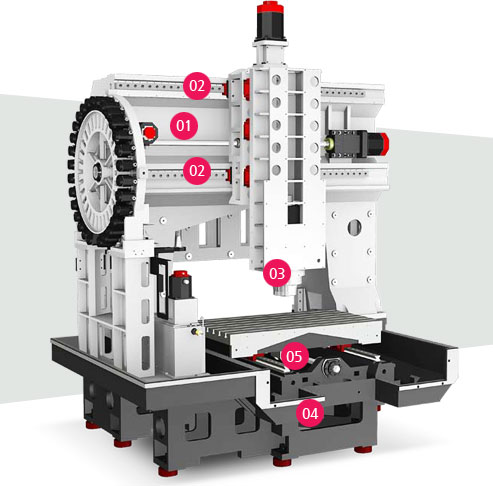

1Wall Type Column Structure

Hi-MOLD6500 is built upon a wall type column frame. The biggest benefit of a double column machining center is the increased rigidity and less heat generated. Hence, it retains accuracy and repeatability at the highest levels.

2

Step Type of Column Structure

Since X axis cross beam of column had been desinged with step type, it had reduced the load that occurs on the front during the product processing. In additional, the transfer stability had been increased by optimizing the column's weight.

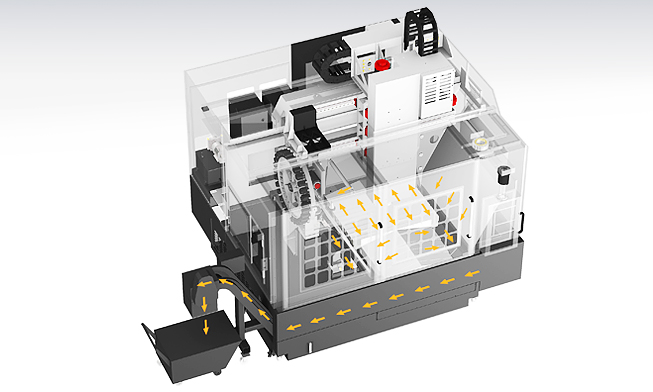

Grease Lubrication Method Guideway

Because the lubricant which is injected to both LM guide block and ball screw nut is adopted as the grease lubrication method, we can save more than 33 times of the consumption of lubricant compared to the oil lubrication method.

-

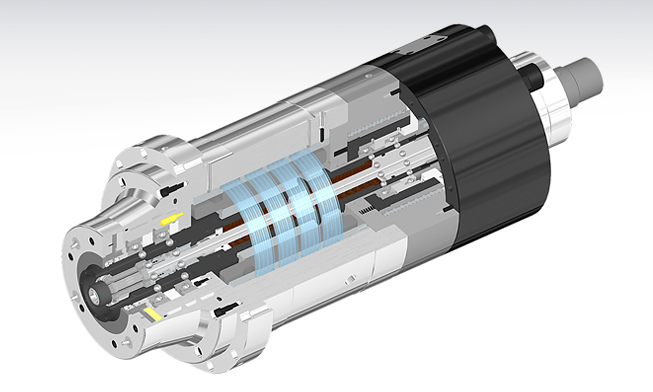

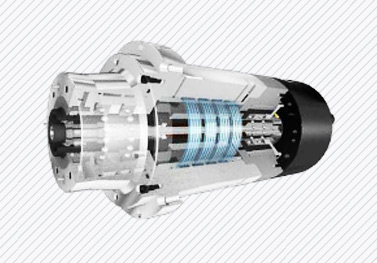

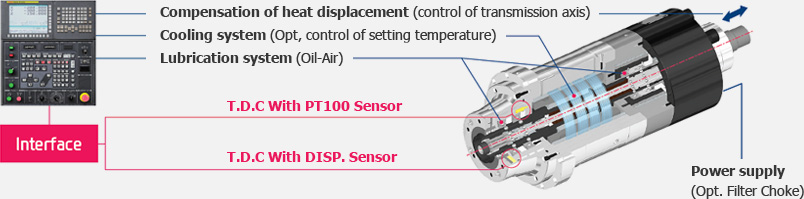

3Built-In Spindle

By using ultra precision class angular bearings, fast acceleration and deceleration of the main spindle is achieved.

-

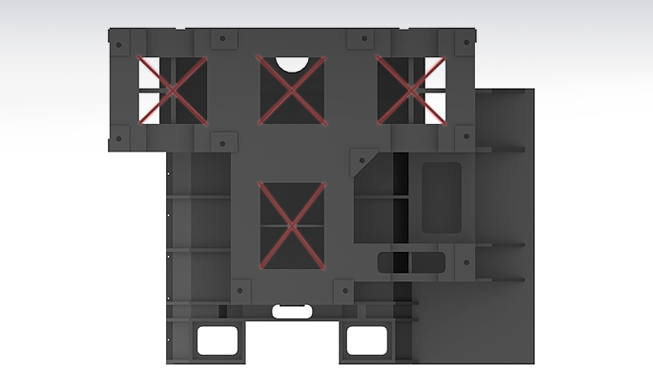

4X Type of Rib Structure Bed

Hi-MOLD6500 was manufactured with X type and high rigid of Rib structure, and it showing the best performance in the high quality of mold machining, due to excellent vibration absorption, powerful cutting and high precise machining.

-

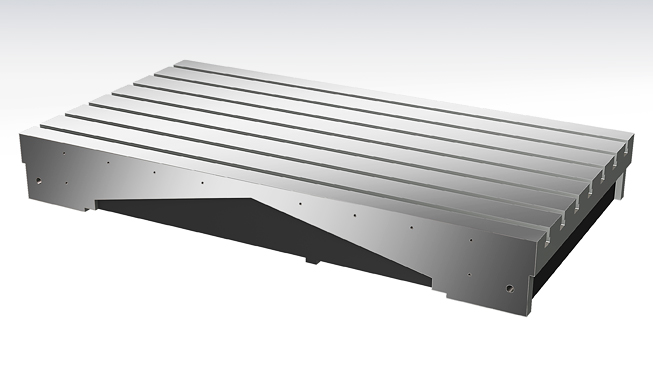

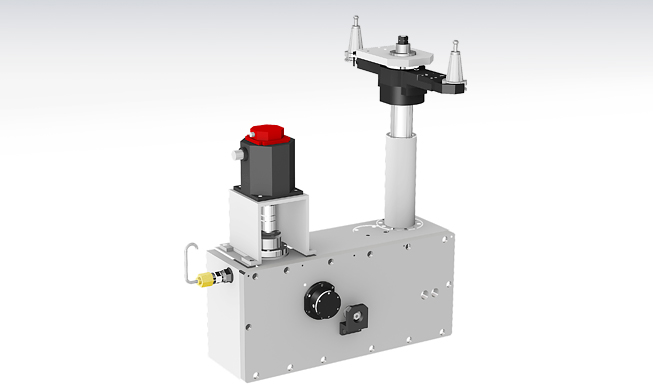

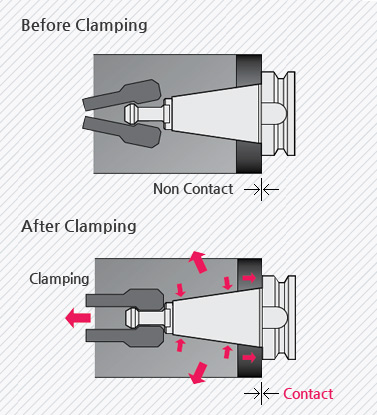

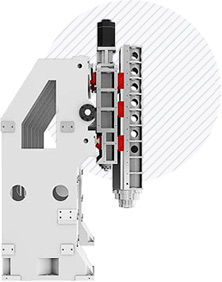

5Nut Cooling Ball Screw

HI-MOLD6500 has also adopted ball screw nut cooling system which protects travel axes from thermal deformation.

R&D Story

Research Engineer, Yang soonsin

M/C design team