New Product

KF5700B/6700B/7700B Excellent Heavy Duty Cutting Capability & Productivity Vertical Machining Center

The Vertical Machining Center KF-B Series, designed by Hyundai WIA with years of expertise and the latest technology, maximizes productivity while maintaining rigidity and accuracy.

The Fastest, the Most Versatile High end Linear Machining Center

- Box guideways for exceptional feeding during heavy duty cutting

- High-powered, high-torque main spindle for superb heavy duty cutting

- Main spindle with gear drive for high-power and high torque (BT50 Option)

- Latest Servo ATC for highly efficient tool exchanging

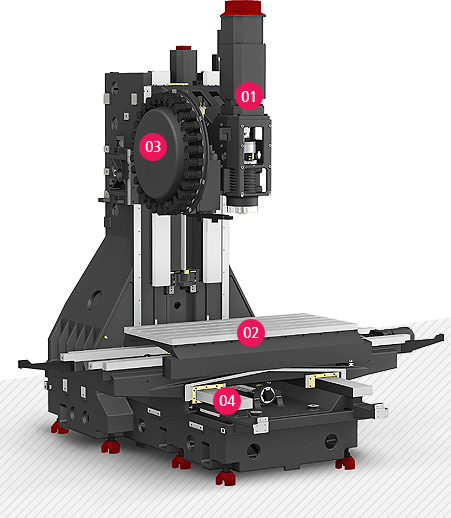

Basic Features

Excellent Heavy Duty Cutting Capability & Productivity Vertical Machining Center

KF5700B Travel

| Travel (X/Y/Z) | 1,100/570/520 mm (43.3″/22.4″/20.5″) |

KF6700B Travel

| Travel (X/Y/Z) | 1,300/670/635 mm (51.1″/26.4″/25″) |

KF7700B Travel

| Travel (X/Y/Z) | 1,500/760/635 mm (59″/30″/25″) |

KF5700/6700/7700B Traverse Rate

| Rapid Traverse Rate (X/Y/Z) | 30/30/24 m/min (1,181/1,181/945 ipm) |

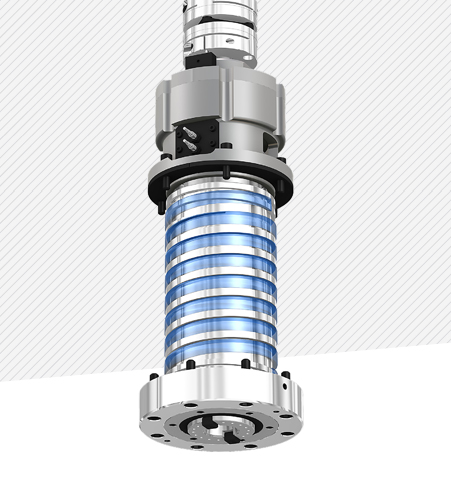

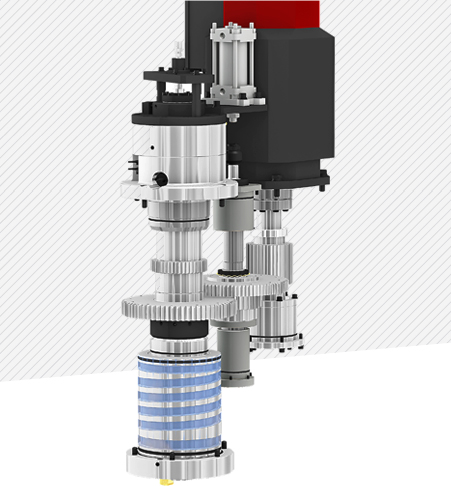

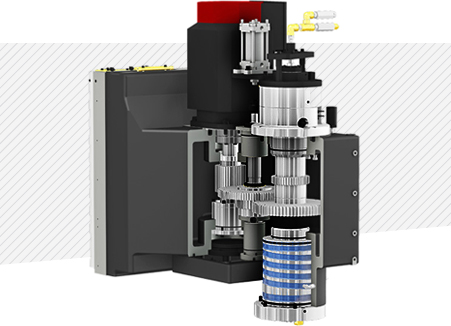

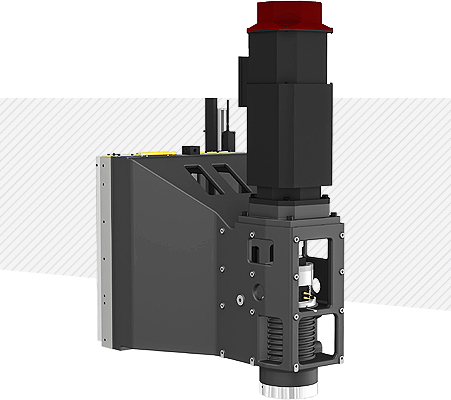

1Direct Driven Spindle

he motors and spindles are directly connected, thus shortening the spindle's acc./deceleration time. To achieve higher speed of the spindle, the design involves super-precision, hi-speed angular ball bearings, enabling an increased machining capability.

Gear Driven Spindle OPTION

he KF-B Series can be fitted with a gear-type spindle shift as an optional feature so ensure a shift to stable rotation at high speed from strong torque at low speed, thus offering a wider range of machining.

Direct Driven Spindle (BT40, BT50)

8,000 / 12,000 rpm

Gear Driven Spindle (BT50)

8,000 rpm

※Thermal Displacement Compensation as Standard

< Gear Driven >

< Direct Driven >

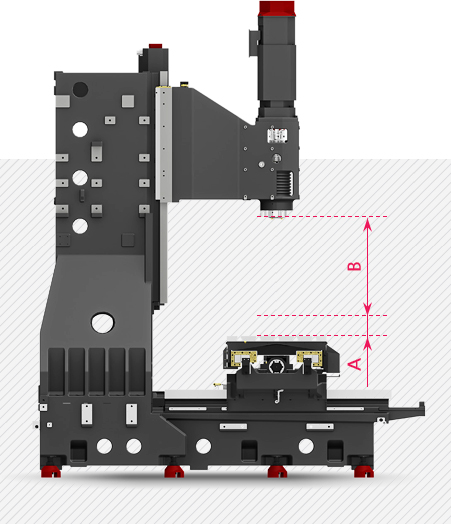

2Table

Compared to competitive machines, the KF-B series has a large working capacity to make setup easier and provide convenience to the operator.

| Model | KF5700B | KF6700B | KF7700B |

|---|---|---|---|

| Size | 1,300×570 mm (51.2″×22.4″) |

1,500×670 mm (59″×26.4″) |

1,650×760 mm (65″x30″) |

| Load Capacity |

1,000 kg (2,205 lb) |

1,300 kg (2,866 lb) |

1,500 kg (3,307 lb) |

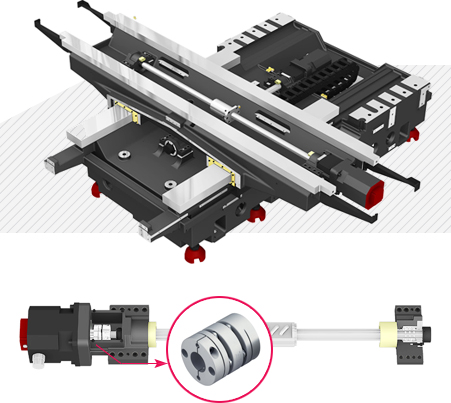

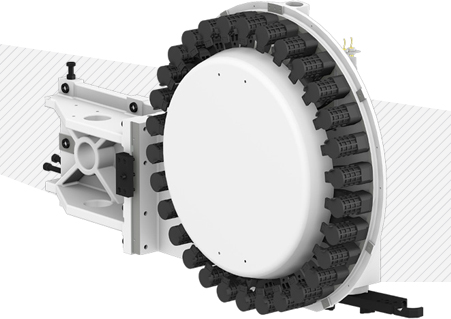

3ATC & Magazine

The tool magazine holds 30 tools as standard and 40 tools(BT50 : Std. 24EA, Opt. 30EA) as an option. Due to the wider selection of tools and the random tool selection method, tool change time has improved.

Tool Change Time (C-C) : 3.5 sec

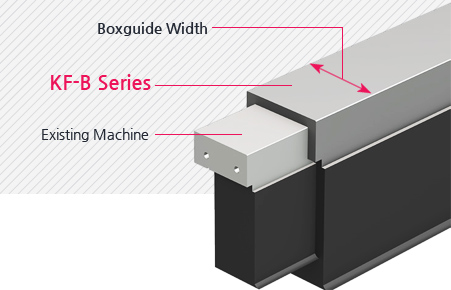

4All Axis Large Boxgide way

Capability of heavy-duty cutting and vibration absorption is enhanced drastically due to expanded box guide.

| Division | X Axis Width | Y Axis Width | Z Axis Width |

|---|---|---|---|

| KF6700B | 100mm (3.9″) | 160mm (6.3″) | 125mm (4.9″) |

| Existing Machine |

100mm (3.9″) | 100mm (3.9″) | 100mm (3.9″) |