Software

HYUNDAI Intelligent Control

Next-Generation Controller for Convenient Use and Maintenance with Effectiveness

Convenient Controller

- Simplified UX/UI design for easy use (prompt response when problem occurred)

Various S/W Functions

- Various convenient functions for high-speed & precision of machining

- Provide management function by date/work

- Remote IT solution afford monitoring, alarm and e-mail services of machine status

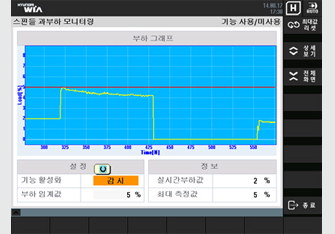

Tool monitoring and AFC

(Adaptive Feed Control)

- Real-time monitoring of tools and machining conditions by machining load (detection of abrasion, damage, omission)

Machining Process Monitoring

- Machine coordinate, work coordinate, relative coordinate and remaining distance displayed in one screen

- Intuitively view of spindle load, RPM meter, and machining progress

- More intuitive screen displaying work counter divided into 8 segments

- Easier identification of activated work coordinate and tool names

- A shortcut key added to PPU buttons

Measuring System

- Simplified UI by removing unnecessary screens

- Compatible with the standard Renishaw/Marposs as well as third-party TLM (the measuring program needs to be converted into TLM.SPF)

- Continuous measuring function to measure 10 tools at a time

- Tool data comparison (before and after measuring) and enhanced animation function

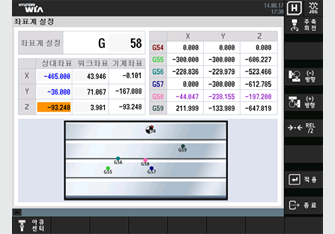

Coordinate System Setting

- Quicker setting of coordinate system enabled by an improved UI (using the top-left coordinate system value)

- Parameter change process has been changed to "enter all and apply later" type to prevent the worker’s erroneous entry

- Pre-defined coordinate value displayed in the bottom bed image for easier identification

- A ‘Spindle rotation’ button added for easier spindle rotation

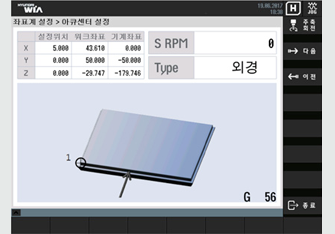

ACCU CENTER Setup

- The ACCU CENTER measuring screen that is most frequently used for work setup

- Upon selecting a position for the reference point, a guide with an image shows up, enabling you to easily set the coordinate system using the guide.

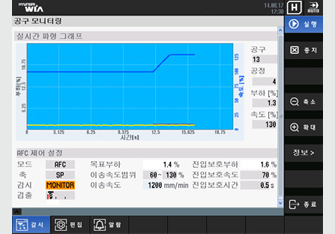

Tool Monitoring, AFC

- The same tool monitoring function as the Fanuc HW-TM + new AFC

- Automatic transfer speed control

- Expected benefits : Tool monitoring possible even when machining molds and prototype products, etc. Shortens the cycle time and protects the machine through an active control function

- Provides functions similar to the specialized company's product (Omative)

Spindle Monitoring

- Real-time graph display of the spindle load value and monitoring load value

- Intuitive setting of target load value using a graph view of load during machining

- Graph zoom using the ‘Full Screen View’ and ‘View Details’ buttons on the right

- The smart control (AFC) function has been migrated/integrated into the tool monitoring function

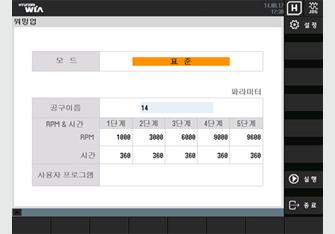

Warming-up

- The mode selection path simplified with an improved UI

- Except Tool, Spindle RPM, Time, Program, the parameters not used frequently have been moved to ‘Settings' screen.

- Messages for the current progress (%) and remaining time displayed at the top of the screen

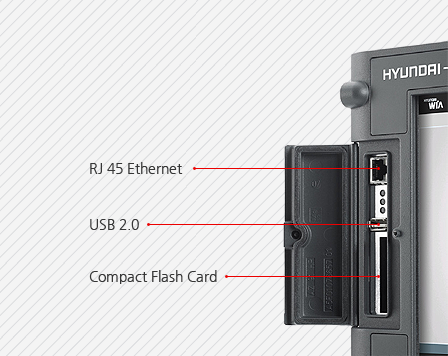

COMMUNICATION FUNCTION

COMMUNICATION FUNCTION

Easy input/output of program is possible with the use of USB memory card, CF memory card and LAN.

You can use energy saving function(ECO) and machining optimization function (SMART) with the MCP button.