Software

- QualityQuality

- ProductivityProductivity

- ConvenienceConvenience

- SafetySafety

| ITEM | FUNCTION | FANUC | SIEMENS | HEIDENHAIN | |

|---|---|---|---|---|---|

|

WIA CAM System Easy CAM system that’s programmable on all level users |

DPRO | ||||

|

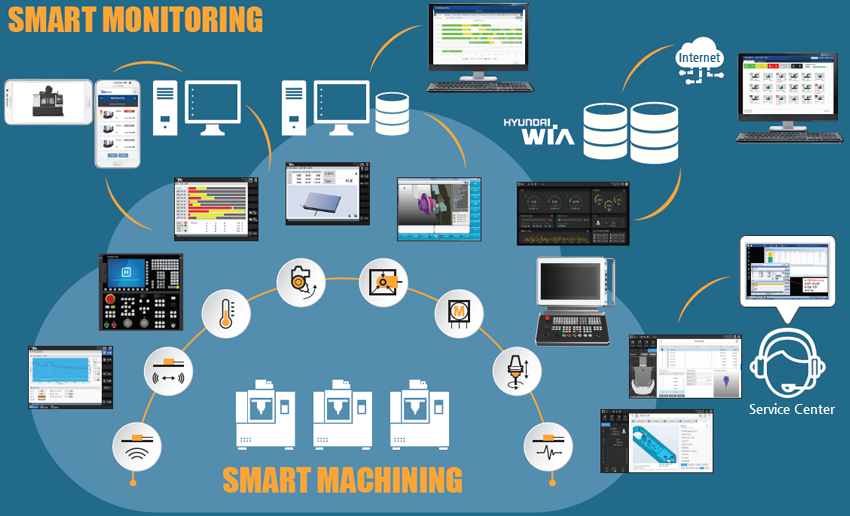

Machine Monitoring System Remote monitoring of the machine tools |

Quality Productivity Convenience Safety | ||||

|

Tool Monitoring Detects tool issues |

Quality Productivity Convenience Safety | (S840D) | |||

|

Tool Monitoring & Control Advanced tool monitoring and optimization |

Quality Productivity Convenience Safety | (S840D) | |||

|

Adaptive Feed Control Controls speed based on spindle load |

Quality Productivity Convenience Safety | ||||

|

Machining Condition Selecting Auto sets parameter per job |

Quality Productivity Convenience Safety | ||||

|

Tech Cycle Auto generates machining cycle for repetitive or complicated operation Machine Monitoring |

Quality Productivity Convenience Safety | ||||

|

Thermal Error Compensation Thermal error compensation for machining stability and reliability |

Quality Productivity Convenience Safety | ||||

|

Tool Length Measuring Easy and fast tool measurement on the screen |

Quality Productivity Convenience Safety | ||||

|

Work Coordinate Setting Easy and fast coordinate system setup on the screen |

Quality Productivity Convenience Safety | ||||

|

Kinematic setting Sets rotating kinematic for 5 axis machine |

Quality Productivity Convenience Safety | (S840D) | |||

|

Energy Saving Energy management solution that reduces standby power consumption |

Quality Productivity Convenience Safety | ||||

● : Standard ○ : Option