Software

HYUNDAI Intelligent Control

The Powerful CNC platform for Machine Tools

HYUNDAI-iTROL+ & SIEMENS Motor & Drive provide the best solution!

119 inch Multi-touch Monitor

2Convenience enhanced White Grip

3Quick Function Bar

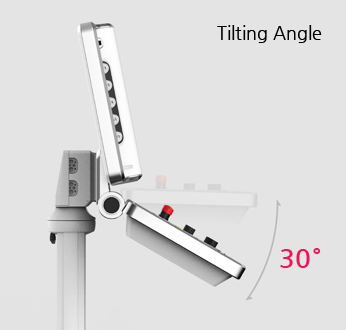

4Keyboard/MCP Integrated Panel that enables 30° folding (Keypad LED Lighting)

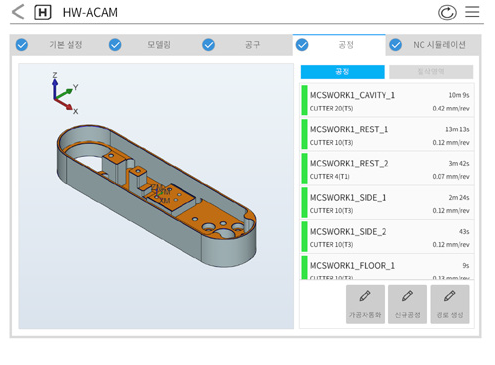

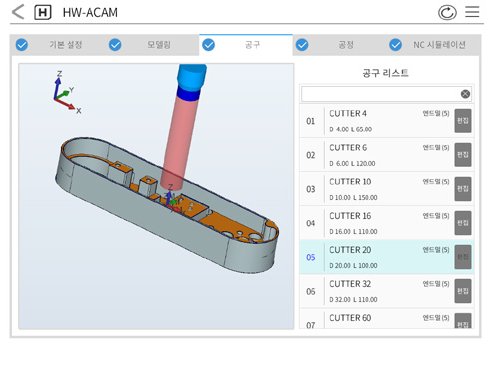

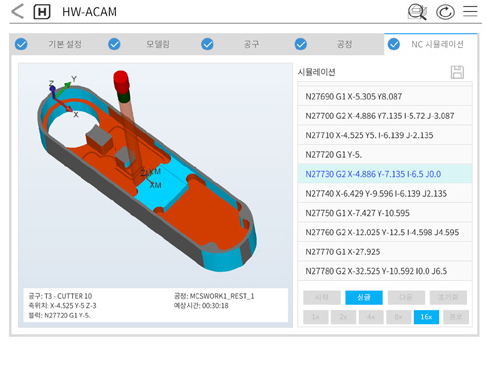

HW-ACAM for Automatically Generating Machining Programs

Automated-machining program

- Input 3D files with USB

(without 3D files, convenient 3D modeling function is available)

Synchronized Tools

- Set and specify tools in program for ready quickly

Automatically generating NC programs

- Analyze work shape and create tool path

Simulation

- Machining simulation based on NC program

-

Input 3D File

-

Tool Synchronization

-

Create Automatic NC Program & Machining Simulation

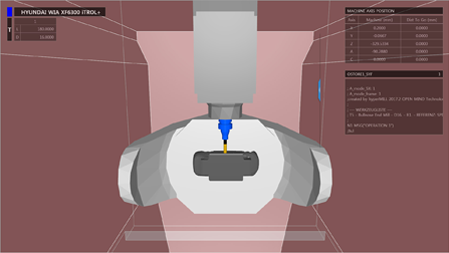

Collision Avoidance Function by Abnormal(Manual) Control

Virtual simulation prevent the collision that can occur from manual operation

3D virtual monitoring based on real-time information

Function properties

- NC requirements : iTROL+ / SIEMENS

- Function works in manual mode

- Covering whole range of machining speed

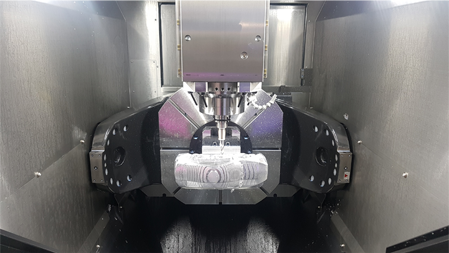

Machining-optimized Application for the Enhancement of Productivity

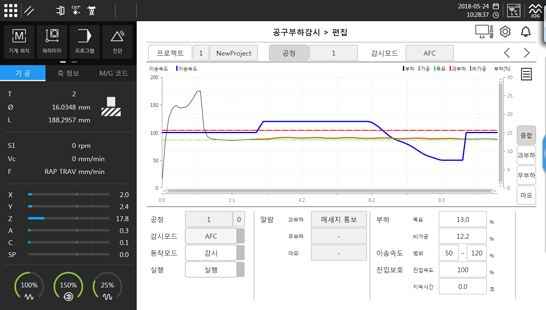

Tool Monitoring

- Monitor the machining load to diagnose tool status and control machining feed

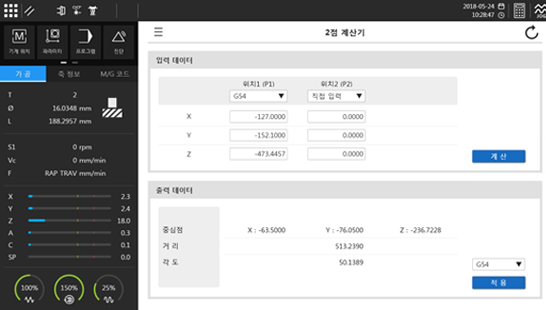

Machine Calculator

- Calculate the machining condition and workpiece coordinate

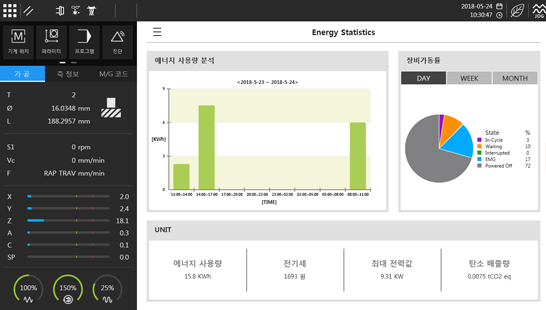

Energy Consumption Saving

- Check and manage energy consumption information through accumulated data

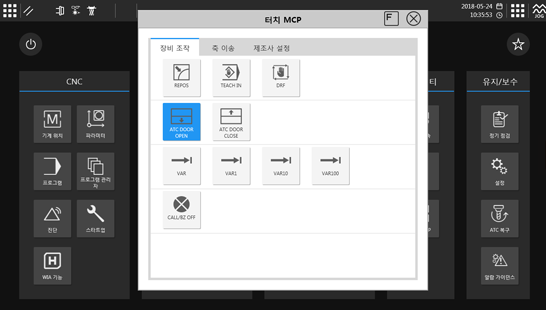

Touch MCP(Machine Control Panel)

- Easy & convenient operation is possible via touch panel

-

Tool Monitoring App

-

Machining Calculator App

-

Touch MCP App

-

Energy Consumption Saving App

-

Energy Consumption Saving App

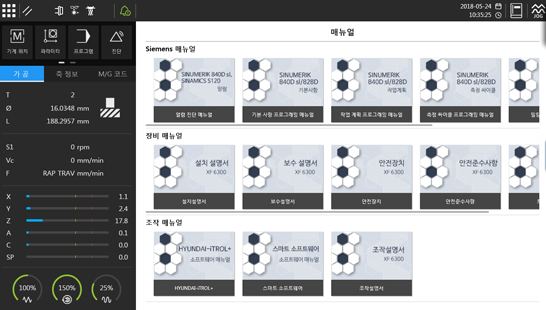

Latest Technology for User’s Smart Factory

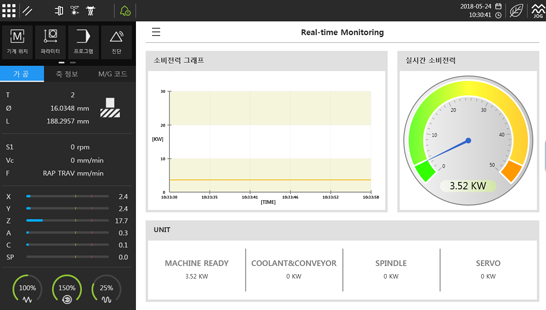

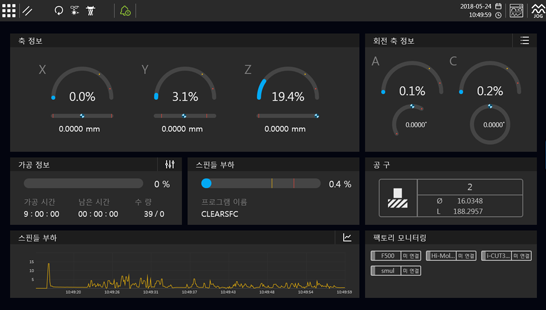

Machine Monitoring

- Easy to figure out machine status at a glance with excellent visibility

Electronic Manual

- E-Manual can be found in application for user convenience

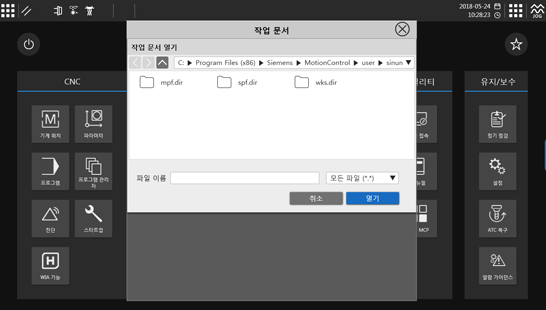

Work Document

- User also can see, note the work documents through application

Factory Monitoring

- Real-time monitoring in overall view, which can also monitor other machines in factory

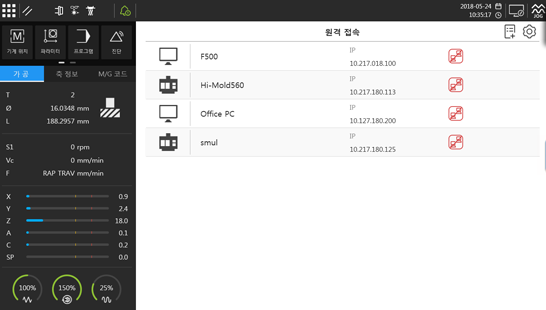

Remote Access

- Control the machine remotely for user convenience

-

Machine Monitoring App

-

E-Manual App

-

Work Document App

-

Factory Monitoring App

-

Remote Access App

Various Applications for Convenient Maintenance

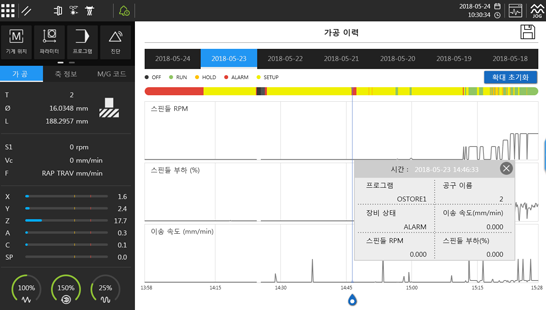

Machining History

- Provide the historical data and graph for the analysis of machining

Regular Inspection

- Notify and save history of machine’s regular inspection

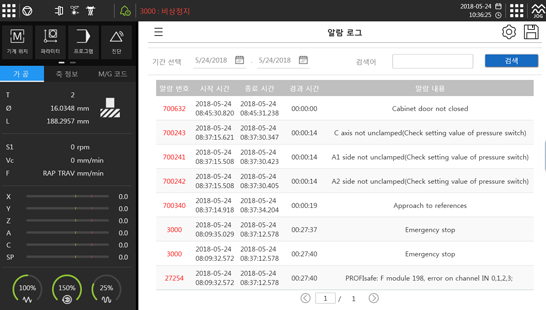

Alarm Guidance

- Statistics and analysis of occurred alarm

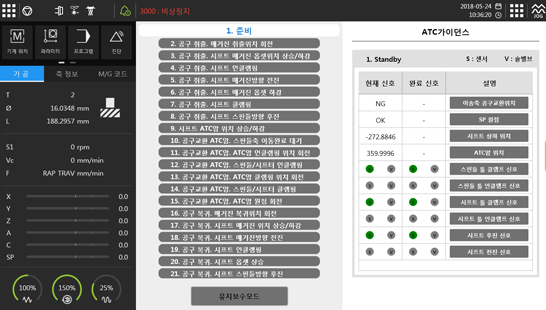

ATC Guidance

- One-touch restoration function when the breakdown

- Check the current status of ATC

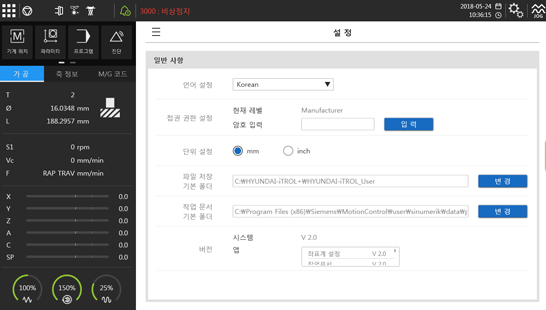

Setting

- Configuration for the user’s taste

-

Machining History App

-

Regular Inspection App

-

Alarm Guidance App

-

ATC Guidance App

-

Setting App