New Product

KF6700B Heavy Duty Cutting Vertical Machining Center

Hyundai Wia, one of the largest machine tool makers in Korea, has used its accumulated know-how and latest technology to develop the KF6700B Vertical Machining Center, which offers high-precision heavy cutting capability and maximum productivity, making it a next-generation machine tool.

Box Guideway Machining Center Specialized in Heavy-duty Cutting

- Box guide design for heavy-duty cutting

- Stable machining – Enlarged box guideway in width and span

- Fundamental rigidity of the structure has secured through the high-rigidity design between column and bed

- Enlarged table size to provide various workpiece options

- Various spindle options and hydraulic tool locking system for a stable machining

- Fast tool change time (C-C: 3.5sec)

- Large size of coolant tank (590ℓ)

Basic Features

Excellent Heavy Duty Cutting Capability & Productivity Vertical Machining Center

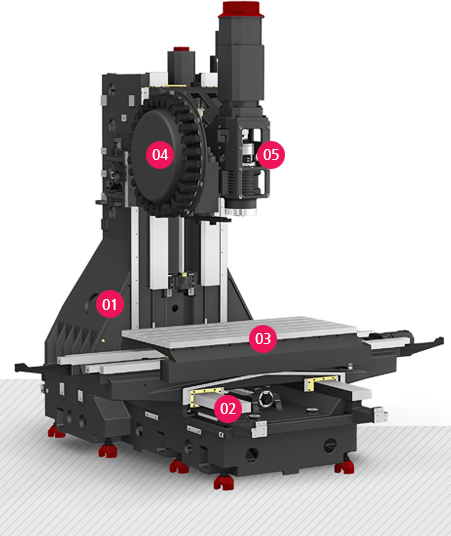

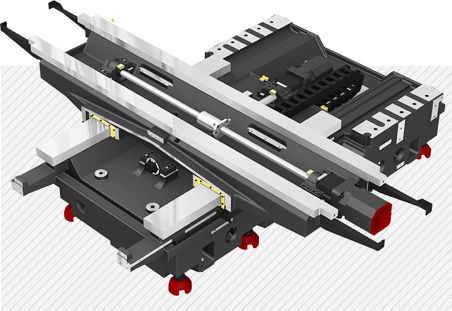

1Optimal Structural Analysis

The KF6700B is fitted with ribs at the bed front to boost structural rigidity, giving it increased static rigidity compared to base machine models and the ability to perform solid heavy-duty cutting.

High-Rigidity Design for Column & Bed

The stable design of column assembly surface on bed top enables securing the fundamental rigidity of the structure.

(Full scrapping of assembly area : 10 fixing bolts)

Optimal rigidity maintained by reinforced rib structure

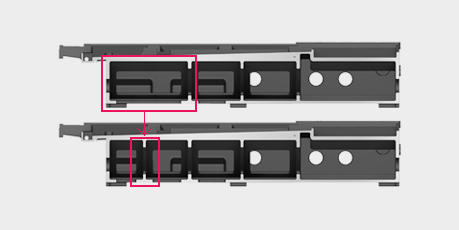

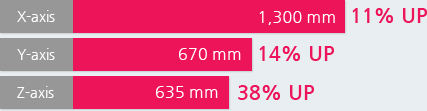

2Box Guideway on All Axes

The KF6700B is equipped with box guideways to enable distributing its feeding force evenly to each slideway. It boasts excellent rigidity, a stable feed structure, and an increased box guide slideway, thus providing an excellent heavy-duty cutting performance.

Increased Box Guide Slideway

| Travel (X/Y/Z axis) | 1,300/670/635 mm (51.2″/26.4″/25″) |

| Rapid Traverse Rate (X/Y/Z axis) | 30/30/24 m/min (1,181/1,181/945) |

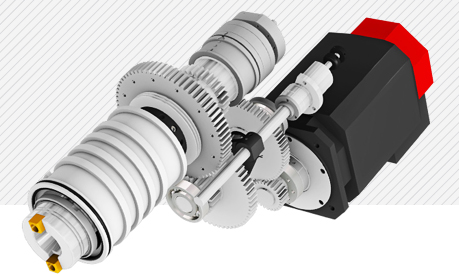

Double-Anchor Type Ball Screws

Precisely preloaded ball screws minimize heat build-up and further boost rigidity based on the double-anchor support method.

In addition, each axis is connected with ball screws and high-reliability digital

servo motors using a metal-plate coupling to reduce coupling damage and backlash.

‘3-row bearings + oil lubrication method’ has boosted the rigidity 147% than before.

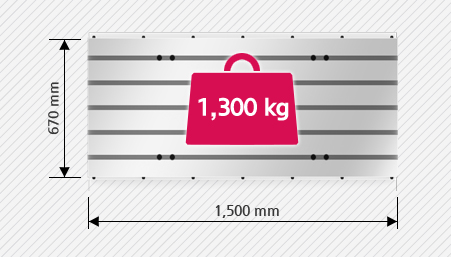

3Enhanced Rigidity Based on Table Structural Analysis

The KF6700B boasts the thickest table design compared other models in its class in Korea and a reinforced rib structure, thereby minimizing able displacement even during high-load workpiece machining..

| Table Size (L×W) | 1,500/670 mm (59″/26.4″) |

| Max. Load Capacity | 1,300 kg (2,866 lb) |

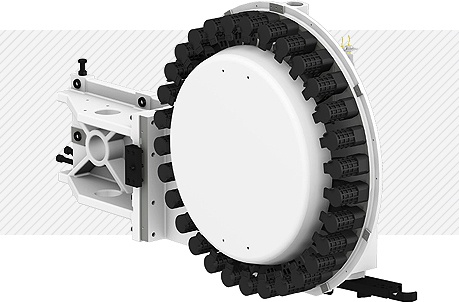

4Magazine & ATC

The machine comes with a magazine capable of carrying 30 tools as a standard, and 40 tools as an option (BT50: 24 tools as a standard; 30 tools as an option), offering a wider choice of machining tools. It also features a randomized tool selection system to shorten the tool change time.

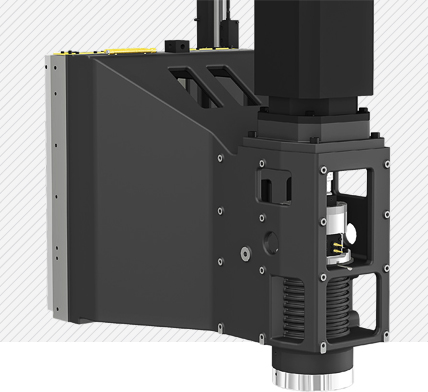

Servo ATC

The servo motor-driven Twin Arm ATC offers greater ATC position control compared to previous models. The tool change speed has been improved, significantly shortening non-cutting time.

- 40 Tool Magazine (BBT40) : Servo Motor

- 30 Tool Magazine (BBT40) : Geared Motor (Opt. Servo Motor)