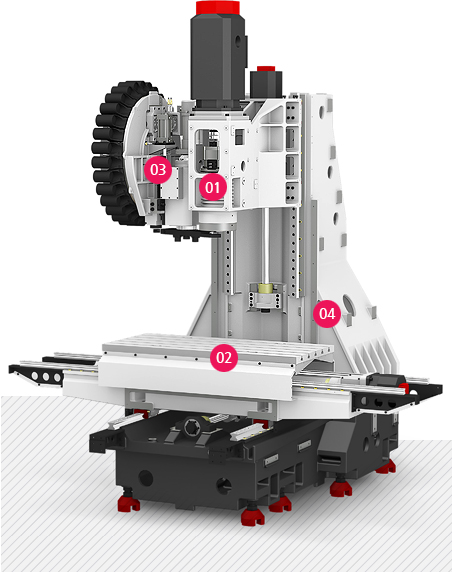

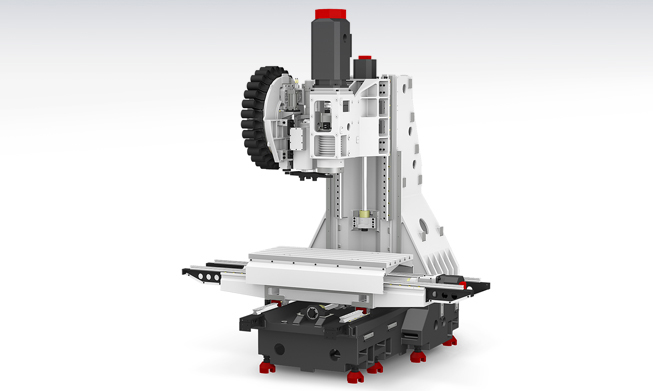

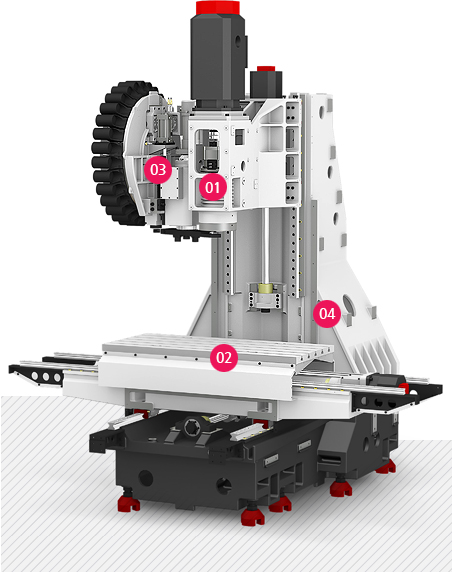

KF4600 Vertical Machining Center

The Vertical Machining Center KF Series, designed by Hyundai WIA with years of expertise and the latest technology, maximizes productivity while maintaining rigidity and accuracy.

The Fastest, the Most Versatile

High end Linear Machining Center

- Diverse spindle structure (direct-connection: 8K, 12K; built-in: 15K)

- Increases strength through structural analysis

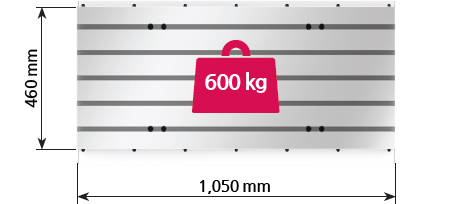

- Expands machining domain with y-axis 460mm design

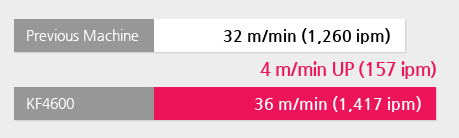

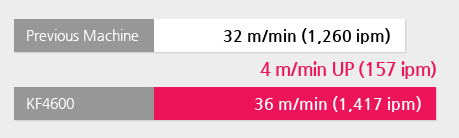

- Shortens not-cutting time with rapid feeds (36/36/36m/min.)

- Mould packages for optimum mould manufacturin

Basic Features

High Speed & Productivity

| Travel (X/Y/Z) |

36/36/36 m/min

35.4/18.1/20.5 inch |

| Rapid Traverse Rate (X/Y/Z) |

900/460/520 mm

1,417/1,417/1,417 ipm |

1

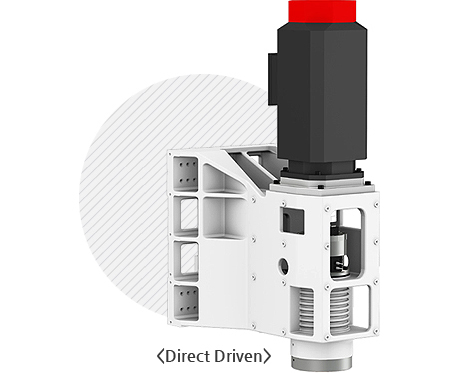

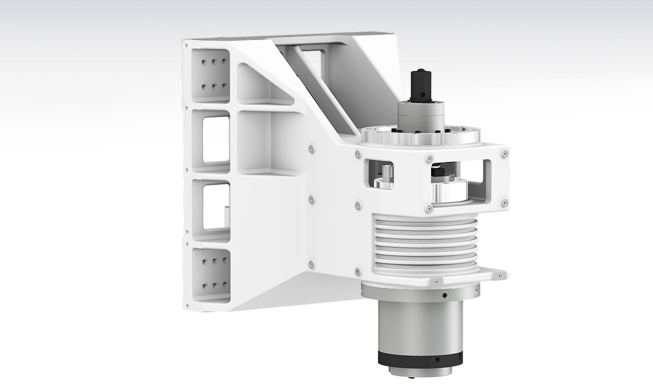

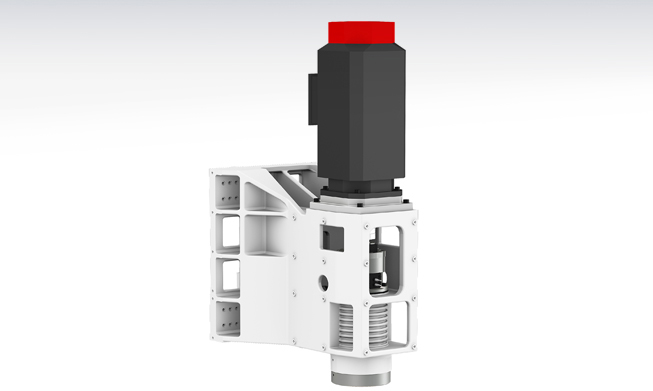

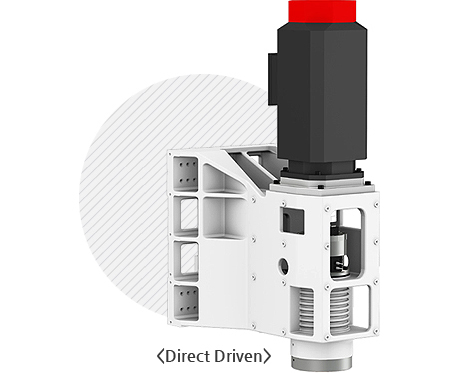

Direct Driven Spindle

By connecting the motor directly to the spindle acc/ dec time was shortened. A wide range of machining can be done with spindle speed of up to 12,000rpm.

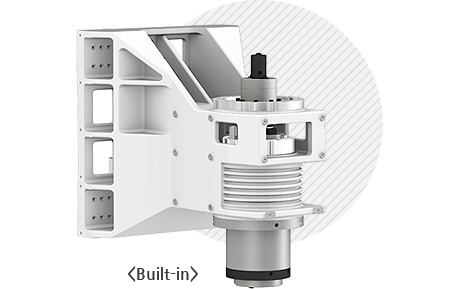

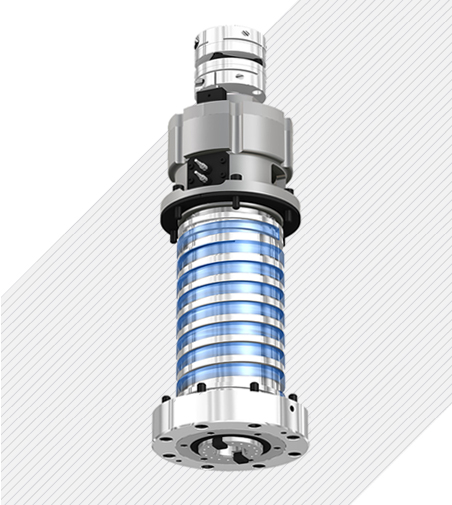

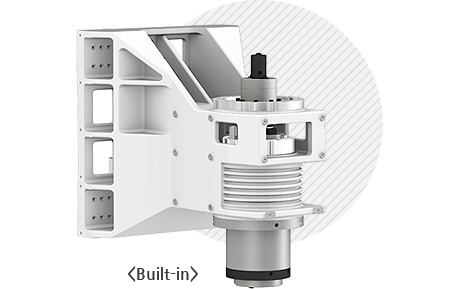

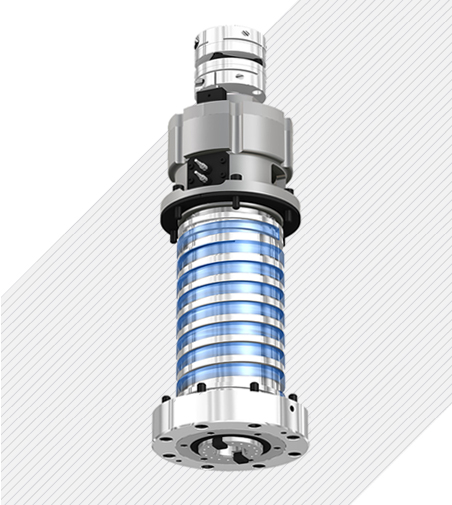

Built-in Spindle

The 15,000rpm built-in spindle can minimize vibration transmitted to the spindle. It allows excellent machining performance in mold and high-precision products.

| Direct Driven Spindle |

8K(β), 8K, 12K |

| Built-in Spindle |

15K |

Standard for Thermal Deformation Compensation(Sensorless)

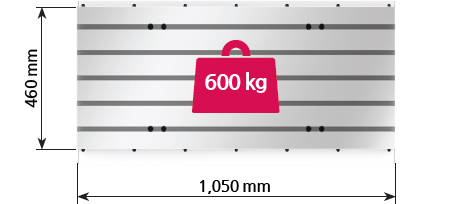

2Table

Compared to competitive machines, the KF4600 has a large working envelope to make setup easier and provide convenience to the operator.

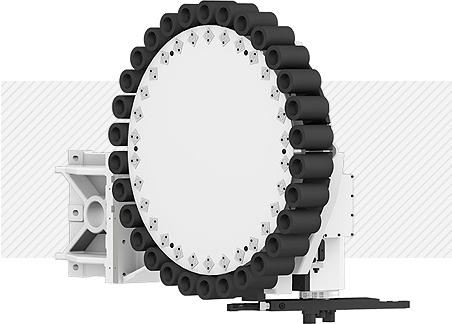

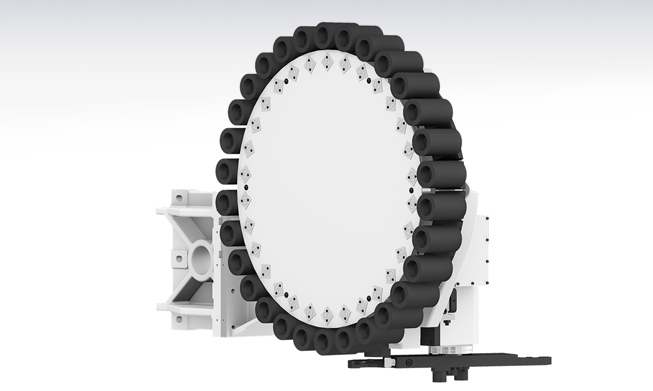

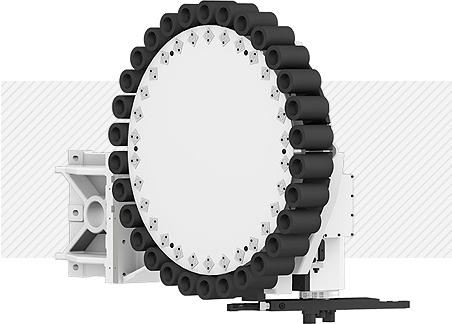

3ATC & Magazine

The tool magazine holds 30 tools as standard and 40 tools as an option. Due to the wider selection of tools and the random tool selection method, tool change time has improved.

Tool Change Time (C-C) : 3.2 sec

4Optimal Structural Analysis

KF4600 is designed to have optimal structure through Hyundai WIA's unique structural analysis. In particular, even with heavy cutting increases the rigidity of the bed and column, excellent performance.

KF4600 Rigidity

| X Axis |

Compared to the previous model 186% UP |

| Y Axis |

Compared to the previous model 158% UP |

| Z Axis |

Compared to the previous model 179% UP |

Slideway

High-Precision & Speed Vertical Machining Center

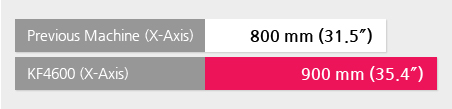

One Piece High Column Structure (8K, 12K)

If you apply an one piece high column with an optional, you cand extend the height of the z axis up to 200 mm (7.9″).

KF4600 (A~B)

| 150~670 |

mm

Distance from Table Surface to SP |

| 5.9~26.4 |

inch

Distance from Table Surface to SP |

KF4600 High Column (A~B) OPTION

| 350~870 |

mm

Distance from Table Surface to SP |

| 13.8~34.3 |

inch

Distance from Table Surface to SP |

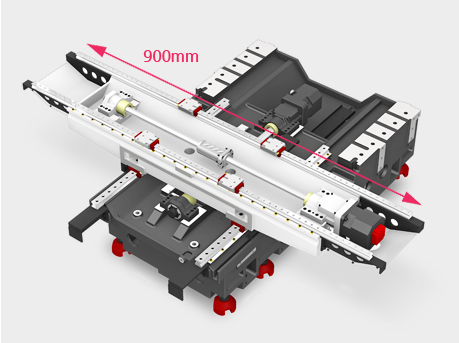

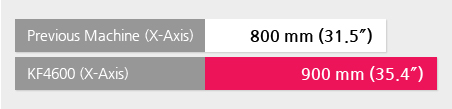

Expanded X-axis Design

The X-axis travel is increased to 900mm(35.4″) and machining area has been enhanced.

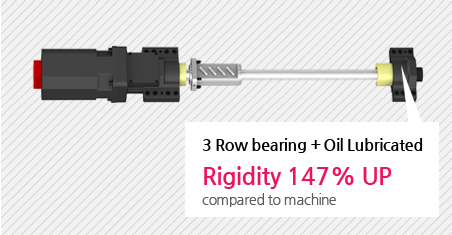

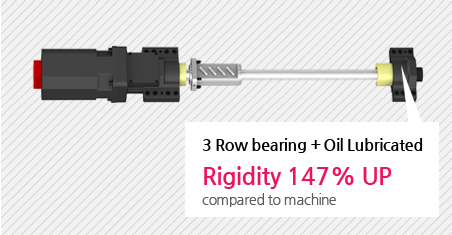

Double anchored ball screw

The precision preloaded ball screw minimizes the expansion and contraction according to the heat and further reinforces the rigidity by the double anchor support method. In addition, the coupling of the ballscrews and the highly reliable digital servo motors are connected by metal plate couplings, and coupling breakage and backlash are reduced.

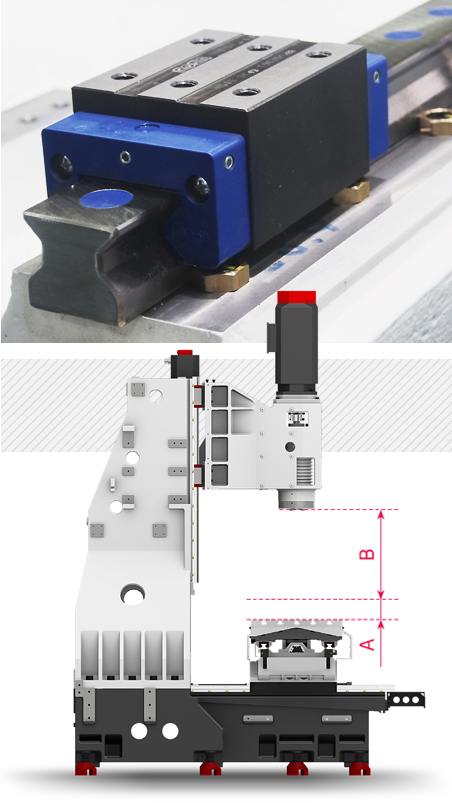

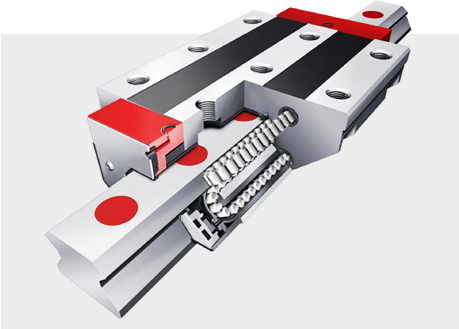

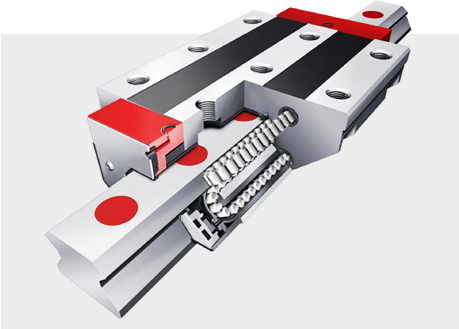

High-Speed Roller LM Guideway

Linear roller guideways are applied to reduce non-cutting time and bring high rigidity.

Ball Bearing Structure Increased 229% compared to LM Guide on rigid X-axis

| Rapid Traverse Rate (X/Y/Z) |

36/36/36 m/min

(1,417/1,417/1,417 ipm) |

Direct Driven Spindle

Long Lasting High Accuracy & Excellent Performance

High-Performance,

Direct Driven Spindle

The directly coupled spindle at a max rev of 12,000rpm, allows high-speed processing. Additionally, the large diameter and the thickness of the spindle add to the stability of the machine.

Spindle Cooling (12K Std.)

The spindle cooling system minimizes thermal displacement which can happen during lengthy machining operations, and offers continued accuracy based on the thermal stability.

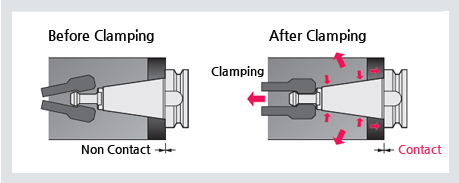

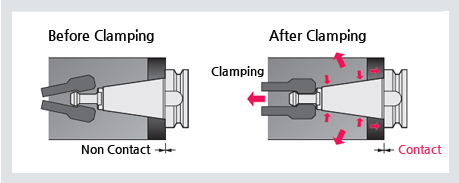

Dual Contact Spindle

The Big Plus spindle system (BBT40) provides dual contact between the spindle face and the flange face of the tool holder.This greatly increases tool rigidity, reduces run out and adds significant productivity to machining applications.

- Tool Lock Type : Hydraulics

Through Spindle Coolant OPTION

Through Spindle Coolant is exceedingly useful when drilling deep holes. It helps increase the lifetime of the tool, while decreasing cycle time.

20 bar / 30 bar / 70 bar

(290 psi / 435 psi / 1,015 psi)

8,000 (β) rpm

| Max. Output |

18.5 kW

24.8 HP |

| Max. Torque |

118 N.m

87 lbf・ft |

8,000 rpm

| Max. Output |

15 kW

20.1 HP |

| Max. Torque |

286 N.m

210.9 lbf・ft |

12,000 rpm

| Max. Output |

18.5 kW

24.8 HP |

| Max. Torque |

118 N.m

87 lbf・ft |