New Product

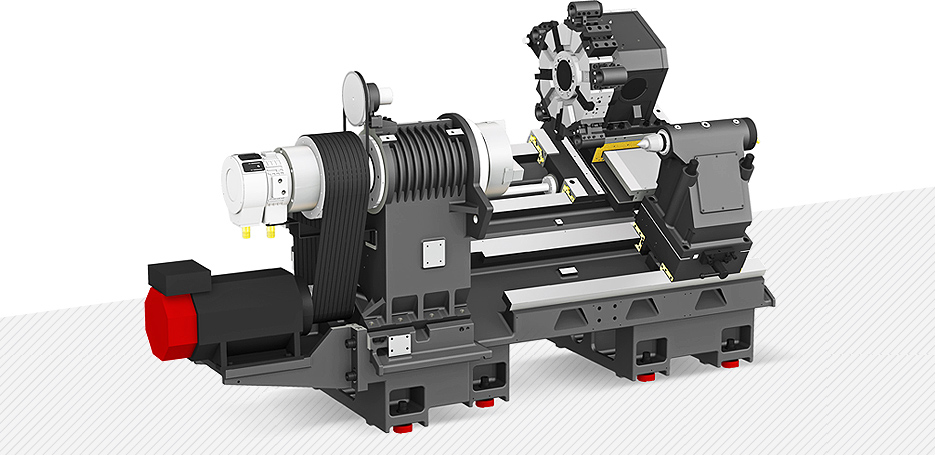

HD2600/3100 Heavy Duty Cutting CNC Turning Center

Hyundai Wia, one of the largest machine tool makers in Korea, used its accumulated know-how and latest technology to develop the HD2600/3100, which delivers high-performance, high heavy cutting capability, and maximum productivity.

High-rigidity, High-reliable Box Guideway

Heavy-duty Cutting CNC Lathe

- 30 degrees of slanted bed to ensure more stable machining

- Stable structure due to high-rigidity and weight-centered design

- Expansion of work space through the long Z-axis box guideway

- Excellent rapid traverse rate : 30m/min (Z-axis)

- Reliable and high-speed servo motor turret

- Box guide design for heavy-duty cutting

- Easy installation with compact machine size

- Upgraded user convenience such as augmented front door, 10.4" operation monitor

Basic Features

The Best Productivity Popular 10 & 12 inch Heavy Duty Cutting CNC Turning Center

1Optimal Structural Analysis

Structural analysis was applied to the design of the machine to increase the tool post body and reduce the machine’s height so as to maintain the bed’s dynamic rigidity even during heavy-duty cutting.

In addition, the HD2600/3100’s bed slope is pitched at 30 degrees to ensure more stable machining.

Increased Tool-Tip Rigidity

| HD2600 | Z-axis 17% UP | Y-axis 49% UP |

| HD3100 | Y-axis 20% UP |

Integrated Coolant Tank

The structure is designed with the coolant tank installed at the bed front for improved convenience. Chips can be removed from the right side of the machine

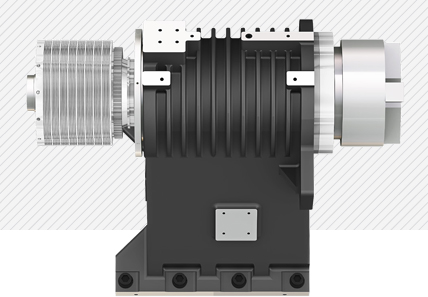

2Box Guideway on All Axes

With the mounting of box guideways on all axes, the machine offers excellent vibration absorption even against during heavy-duty cutting, enabling high-quality machining. In particular, the long Z-axis design ensures the machine delivers excellent performance in machining shafts and other long products.

Closed-type GIB Structure

The guide attachment surface of X-axis guideway has been changed to a sealed GIB structure to minimize X-axis turcite damage caused by chips. As a result, the machining capacity has been greatly enhanced too.

Ball Screw

To prevent the expansion of ball screws due to higher temperatures during feeding, and to remove the feeding axis backlash, the both ends are fixed with 4-row precision angular thrust bearings and are preloaded. In addition, precision axis feeding is enabled with the adoption of a direct-coupled servo motor.

| Rapid Traverse Rate (X/Z axis) | 24/30 m/min (945/1,181 ipm) | |

| Travel (X/Z axis) | HD2600 | 265/680 mm (10.4″/26.8″) |

| HD3100 | 265/830 mm (10.4″/32.7″) | |

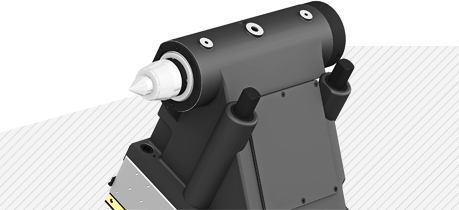

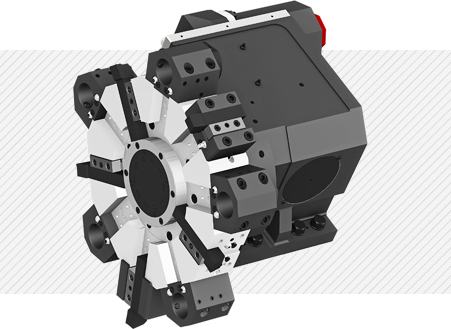

3High-Rigidity Turret for Heavy-duty Cutting

The design features reinforced turret rigidity to withstand heavy cutting and ensure excellent machining. In addition, the width of the turret disk has been increased to further boost rigidity.

| No. of Tools | 10 [12] EA | |

| Tool Size (O.D/I.D) | □25/Ø50 mm (□1″/Ø1.6″) | |

| Indexing Time (1-Step) | HD2600 | 0.17 sec |

| HD3100 | 0.22 sec | |

Disk Width Expand

<Static-Rigidity Increased : I.D 20%, O.D 3% UP>