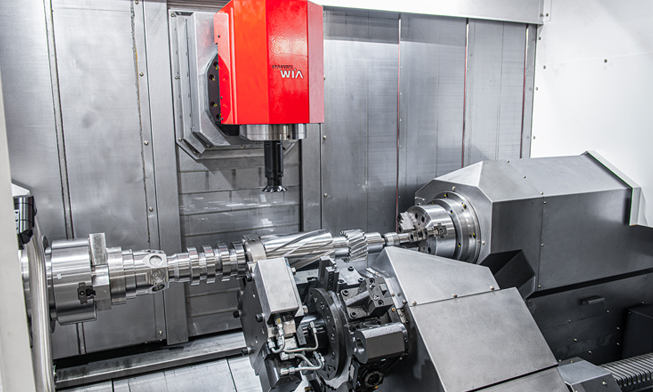

XM2600/3100 Series6/7/9-axis Multi-tasking Machine

Multitasking Machine XM2600/3100 Series, designed by HYUNDAI WIA with years of expertise and the latest technology, is designed to maximize productivity by utilizing mill head and lower turret.

High-speed, high-productivity, high-precision multi-tasking machine

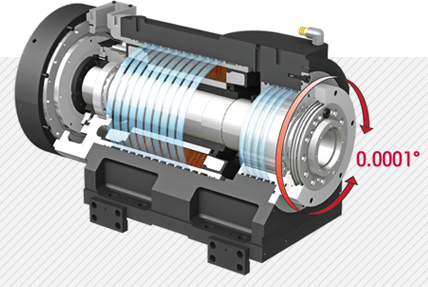

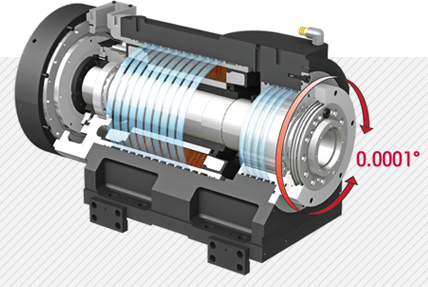

- B-axis driving by DDM (Dircet Drive Motor)

- B-axis indexing ▶ 0.0001˚ control

- Shorten mill head → Enlarged working area

- Enlarged Y-axis stroke → 250mm (9.8”) → 300mm(11.8”)

- Built in spindle ▶ C1-axis 0.0001˚ control

- Adopted nut cooling ballscrew on X1, Y, Z1 axis

- Adopted FANUC 31i-B5 PLUS controller

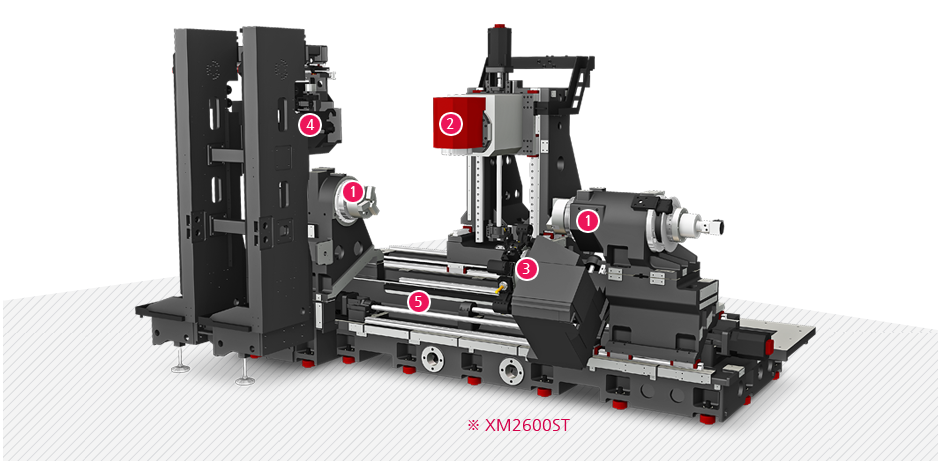

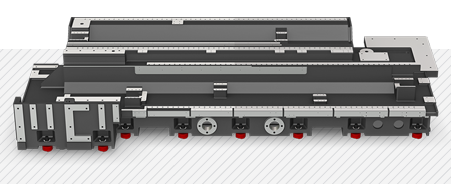

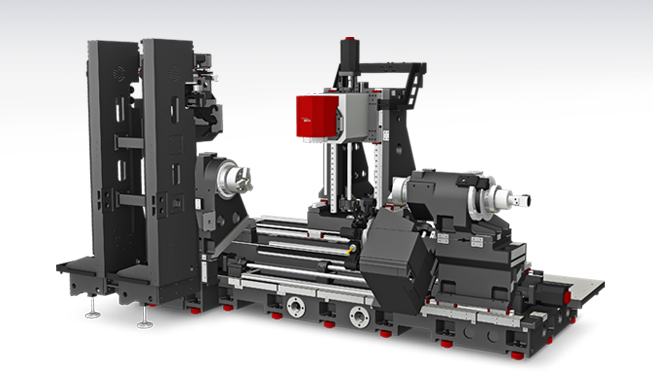

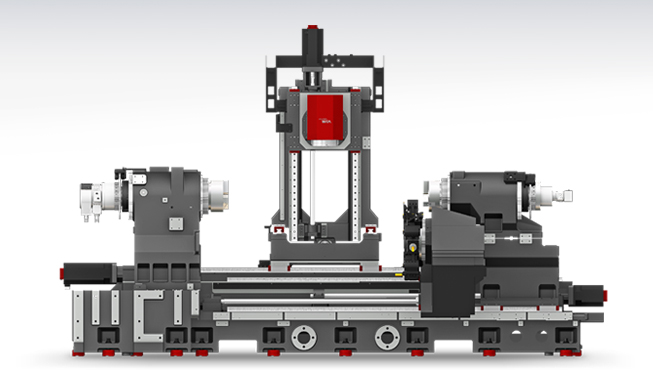

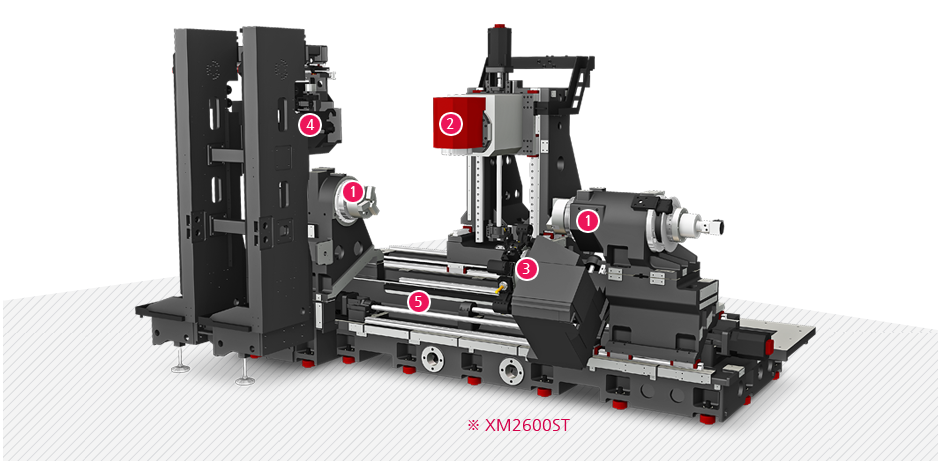

Basic Structure

6/7/9-axis multi-tasking machine

1Built-in Spindle (1st/2nd)

XM2600/3100 Series built-in spindle minimizes vibration to allow machining of the highest precision.

- XM2600 : 10″ Chuck

- Speed : 4,000 r/min

|

- XM3100 : 12″ Chuck

- Speed : 3,000 r/min

|

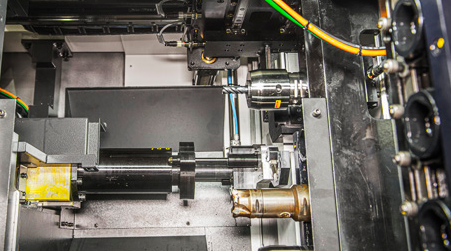

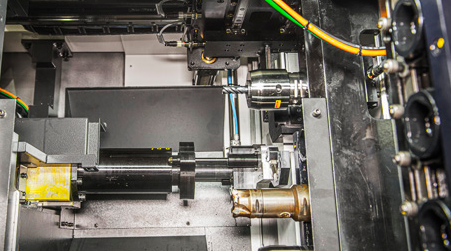

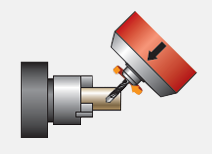

2Compact Mill Head

The B-axis control mill head is mounted with a high resolution encoder having a built-in motor and 0.0001° indexing ability to secure high positioning precision.

- Driving Methode : Built-in

- Speed : 12,000 r/min

|

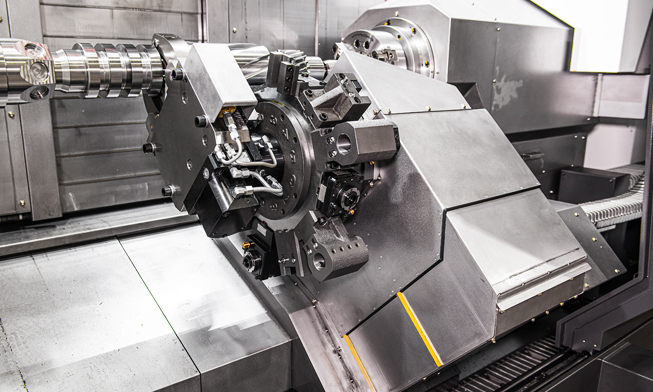

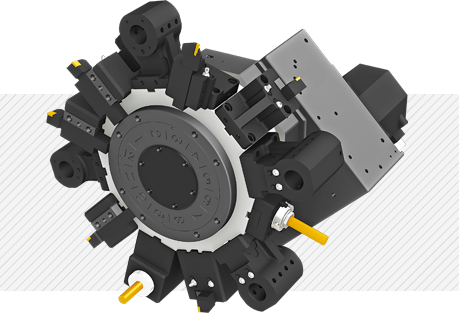

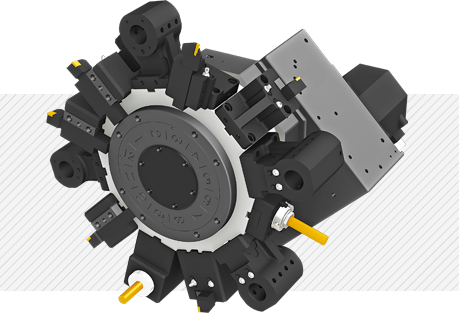

3Lower Turret

(Std. Turning Turret / Opt. BMT65 Mill Turret)

The lower turret ensures high-speed machining of complicated shapes in precision only with one-time setting of workpiece machined with the mill head.

- Type : Servo [Opt. BMT65 - Mill Speed : 5,000 r/min]

|

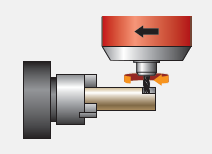

4ATC & Magazine

The installation of magazine on the front provides efficient tool change and tool setting. Magazine with chain driving method provides 40 tools as standard, and 80 tools as option.

- Tool Shank Type : CAPTO C6

|

- Tool Change Step : 4 Step

|

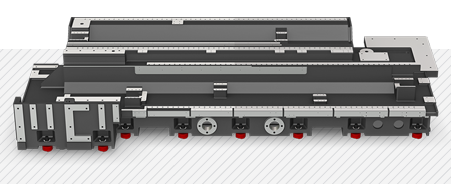

5High Precision & Rigidity Bed

The new bed design has especially been interpreted and designed with the FEM method to minimize various factors such as thermal distortion and vibration, which could take place during machinine. Also to secure machining, XM2600ST is designed low bed structrue compared to previous model.

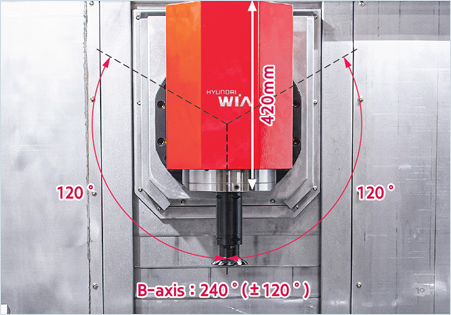

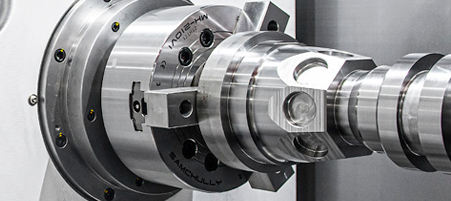

Mill Head

Milling heads for machining complex shapes

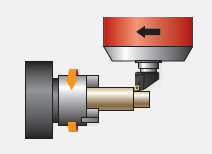

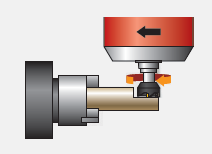

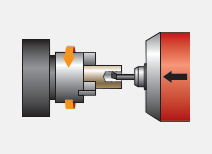

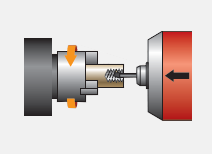

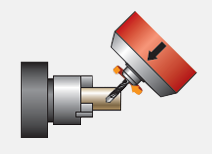

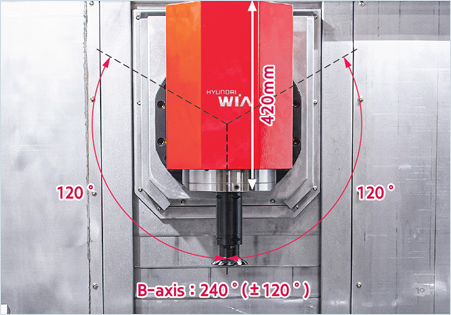

Compact Mill Head with a B-axis Operated by a High-precision DDM

The mill head is a product of combining HYUNDAI WIA’s latest technologies. The B-axis operated by DD motor method(0.0001°) to eliminate rotational backlash and spindle 1 (0.0001°) together can machine impellers, blades and other simultaneous 5-axis machining (standard application). Also, it can perfectly carry out machining of workpieces with complex shape including sloped surface, etc

Mill Head Specifications

| Mill Head Specifications |

Built-in |

| Speed |

12,000 rpm |

| B-axis Travel |

240° (-120°~+120°) |

| Indexing Angle |

0.0001° |

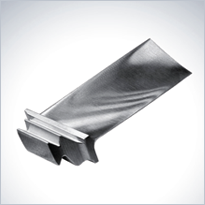

| Tool Shank |

CAPTO-C6 |

CAPTO-C6

CAPTO-C6, which allows double-sided circulation, is applied as a standard for maximum cutting capability.

- - Ideal over load analysis

- - Decreased tool change time by short taper / Excellent cutting ability

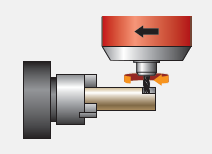

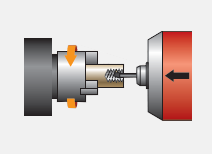

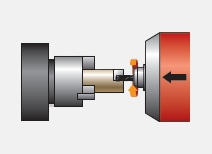

Machining Variation

-

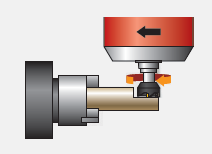

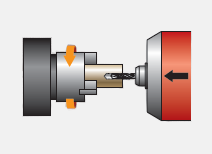

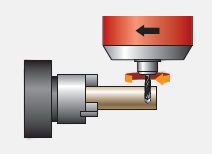

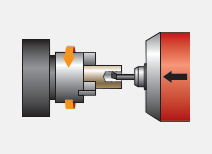

OD Cutting

-

Face Milling

-

Drilling

-

OD Drilling

-

ID Cutting

-

Ball-End Milling

-

ID Threading

-

End Mill

-

Cut-Off

-

Angular Machining

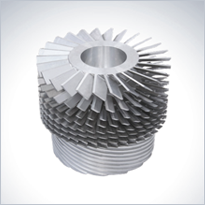

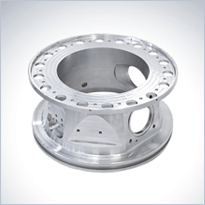

Sample Workpieces

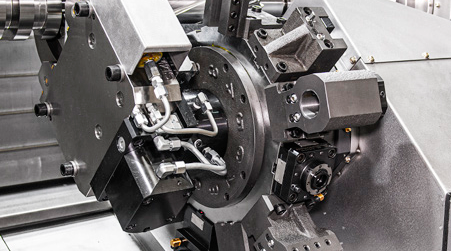

Spindle & Turret

High performance spindle

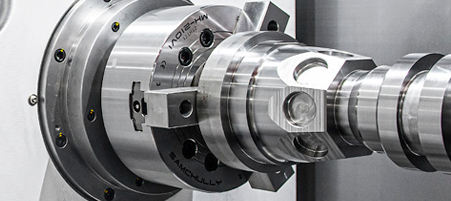

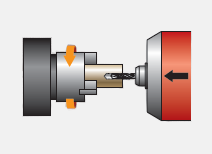

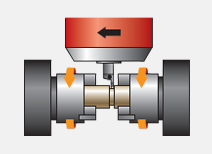

Built-in Spindle (1st/2nd)

he 1st and 2nd spindles with a built-in motor structure can minimize the vibration and heat generated during high-speed rotation, which makes them ideal for high-precision machining.

- 1st Sp. C1-axis : 0.0001°

- 2nd Sp. C2-axis : 0.001°

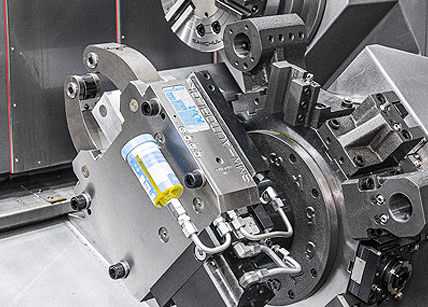

Spindle Oil Cooling

The 1st/2nd spindles have been fitted with cooling units as a standard feature to minimize thermal displacement generated during cutting works, maintain a constant temperature, and increase cutting stability.

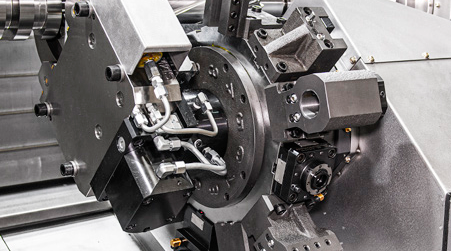

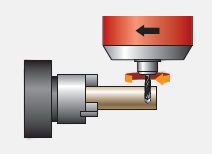

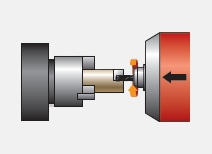

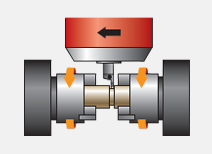

Optional Mill Turret (Std. 12T Turning Turret)

The lower mill turret (Opt.) ensures the high-speed machining of complicated shapes in precision only with the one-time setting of an object to be machined with the mill head and complex machining.

| Speed (rpm) |

5,000 rpm |

| Collet Size |

Ø20 (0.8″) (ER32) |

| ndexing Time |

0.2 sec |

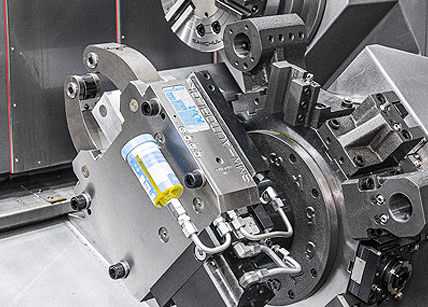

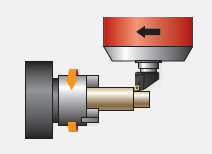

Turret-attached Type Rest OPTION

It guarantees machining stability by preventing tilt and shaking during machining of products such as long shafts. SLU3.2 Rest can also be applied for machining large workpieces.

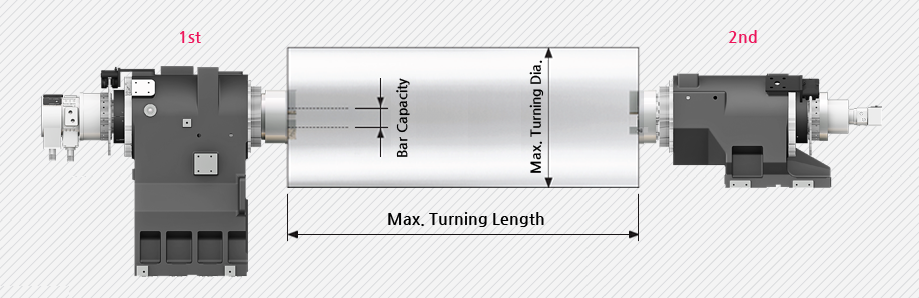

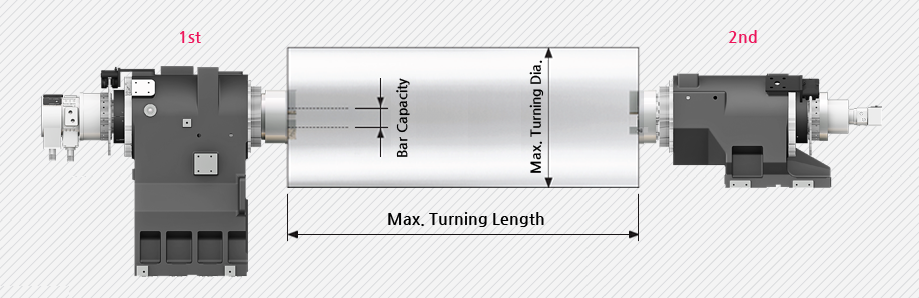

Machining Capability