R&D Centers

Machine Tool Research

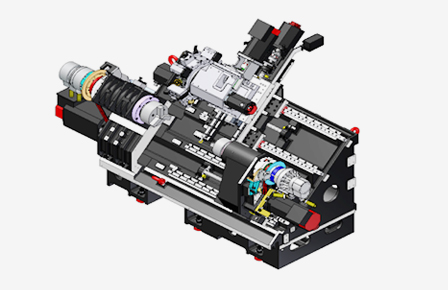

1Turning Center development

- Standard / Multi-Axis Turning Center development

- Special turning center development

- Core product development

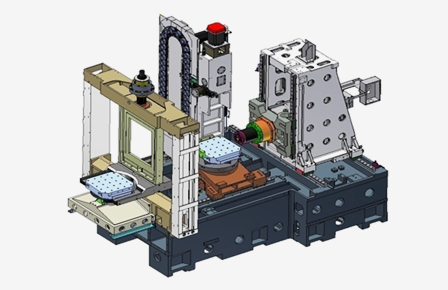

2M/C development

- Vertical/Horizontal M/C development

- Machine for factory automation

- Core product development

Machine tool control and Software research and development

1Machine tool CNC application design

Lathe and machining center optimum control logic design

- Optimization of CNC System

- Multi-Spindle / Multi-Path(Multi-Channel) control

- Optimum application of CNC function

Drive system and peripheral device control

- Turret, ATC, Magazine control

- Hydraulic / Pneumatic Pressure Unit

Operating environment and Electric enclosure design

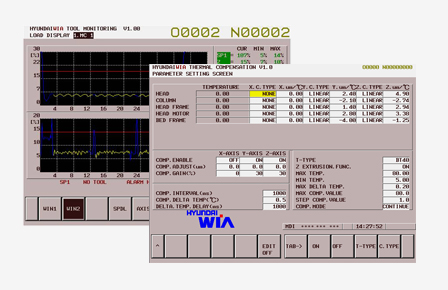

2CNC embedded software design

Develop and implement proprietary functions for Fanuc/Siemens CNC

- Machine operation guide

- Tool path control

- Thermal displacement compensation

- Vibration control

- Eco-friendly control

3PC and mobile based software design

Install and operate with PC and mobile devices (tablet PC, smart phone)

- Remote diagnostic and maintenance

- Virtual machine operation

- Conversational Programing

- Mobile operation / monitoring / control

Machine tool Advanced Research

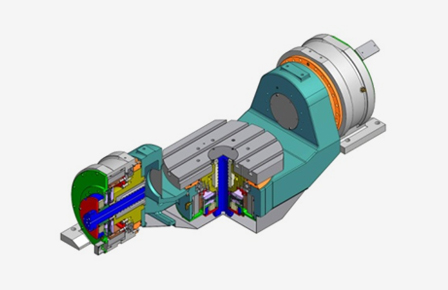

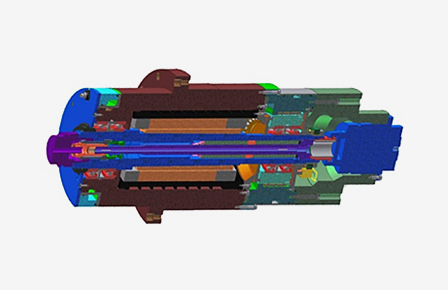

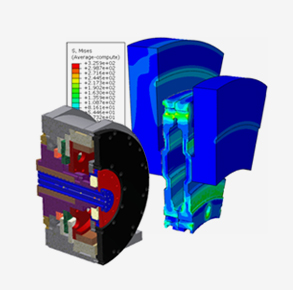

1Core product development

- Development of direct drive motor tilting rotary table

- Development of lathe spindle and tool post

- Development of spindle for machining center

2Development of main spindle

- High power high speed spindle(30,000rpm)

- Nano precision spindle(precision level: 50nm, speed : 40,000rpm)

- Main Spindle thermal displacement sensors and compensation system

Machine tool design verification

-

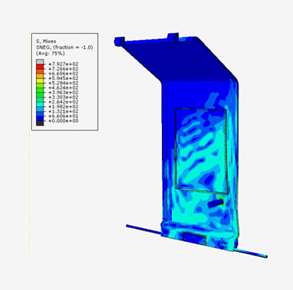

1Structural analysis

- Maximum cutting feedrates, thermal stability

- Static and dynamic deflection analysis, thermal distortion analysis

- Software : ANSYS, ABAQUS

-

2Non-linear analysis

- Clamping force, impact resistance, component fatigue

- Contact Analysis, transient Analysis, fatigue analysis

- S/W : ANSYS, ABAQUS

-

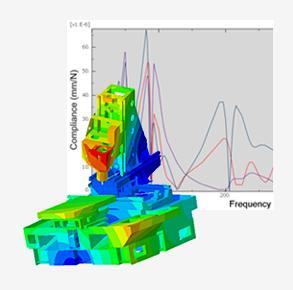

3Dynamic analysis

- Rapid feed rigidity, control/structure coupling characteristics

- Mechatronic analysis, flexible body dynamics

- Software : ANSYS, ABAQUS