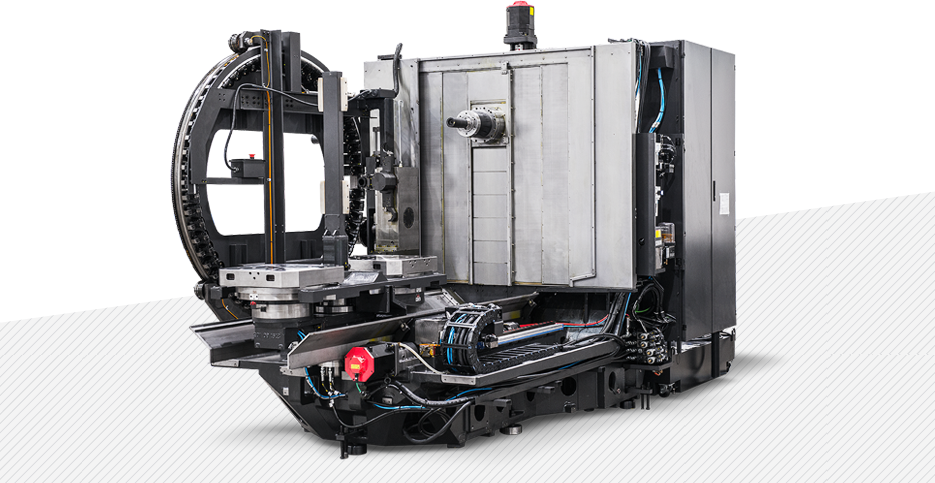

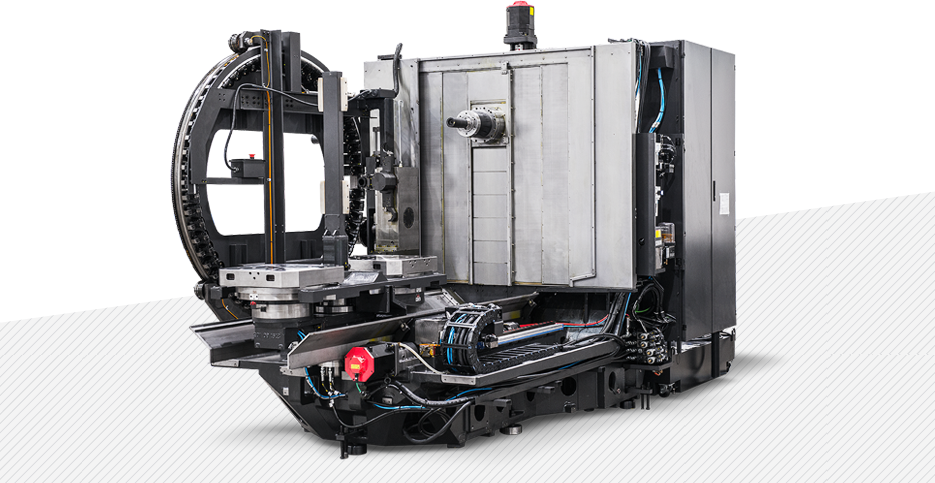

HS5000 II High Speed, Next Generation Horizontal Machining Center

Horizontal Machining Center HS5000 II, designed by Hyundai WIA with years of expertise and the latest technology, provides high speed, high performance and maximum productivity.

State-of-the-Art Mechanism Design, High-Precision Sructure

- 15,000rpm high-performance built-in spindle

- X/Y/Z axis rapid traverse rate : 60m/min

- Ball screw shaft cooling system applied

- High rigidity 3-point support bed structure

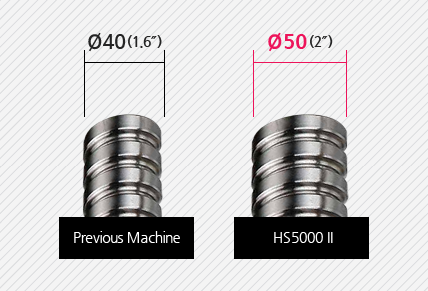

- Large dia. Ø50 mm (2″) ball screw applied

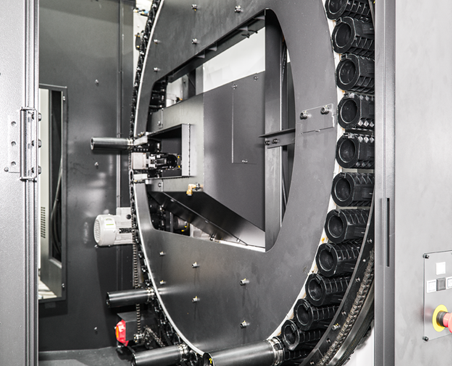

- Ring type magazine standard application

- 60T magazine Max call time : 2.9 sec

- Best-in-class tool change time (c-c) : 2.6 sec

Basic Features

High Speed Next Generation Horizontal Machining Center

115″ Large Monitor Applied

The HS5000 II has a 15″ large monitor for enhanced visibility. In particular, we can create more convenient use conditions by improving the operating environment such as program setup and simulation through a large screen.

2High Rigidity Structure

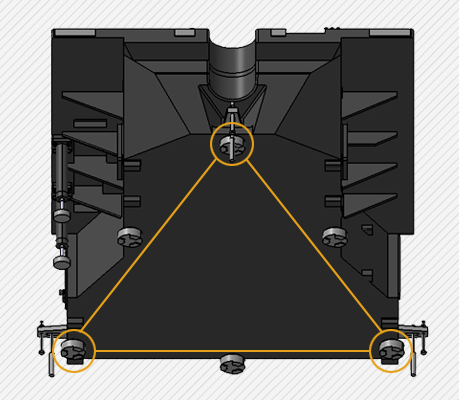

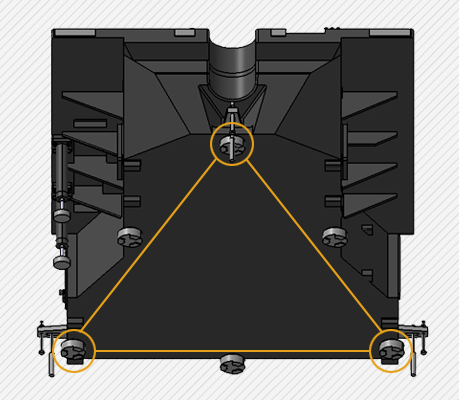

3-point support bed structure

The 3-point support bed can only be achieved with sufficient rigidity of the bed, and it is an indicator of a high rigidity bed. During the initial installation, it is easy to install by leveling only 3 parts of the bed, and even when maintenance is required, the maintenance capability has been greatly improved with easy leveling compared to the previous version..

3-point Support Bed > Minimize installation time

Guideway & Spindle

High Precision Structure & High Speed Machining System

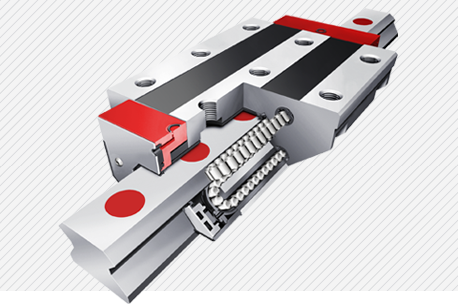

1GUIDE WAY

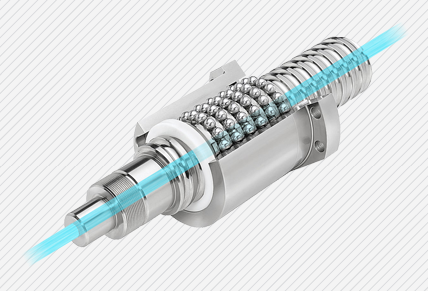

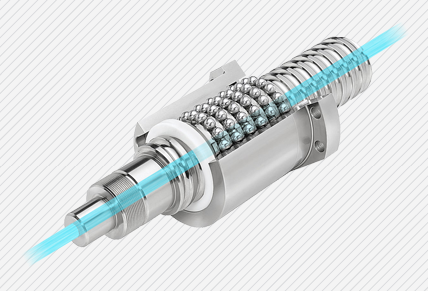

Ball Screw Shaft Cooling

HS5000 II is the company’s first model to apply the shaft cooling method, so it boasts unchanged precision even for long-term processing (for a maximum stroke of 30 round trips).

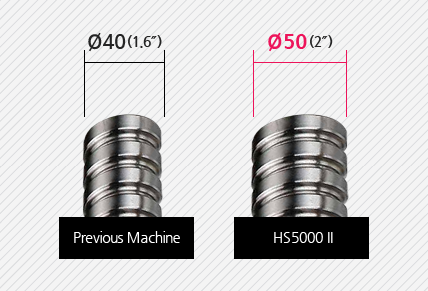

Ø50 (2″) Large Ball Screw

The increased diameters of all ball screws allow for high accuracy even during heavy duty machining.

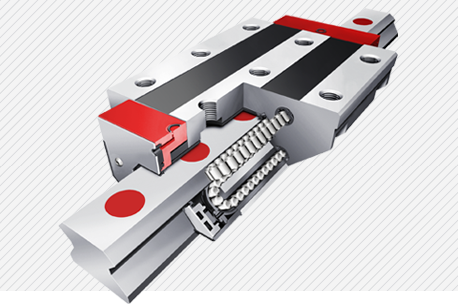

High-Speed Roller LM Guideway

Linear roller guideways are applied to reduce non-cutting time and bring high rigidity. Each axis is directly connected to a highly reliable digital servo motor to provide high rigidity and minimal thermal displacement.

Acc./deceleration speed (X/Y/Z) : 1.0/1.0/1.0G

| Rapid Traverse Rate (X/Y/Z) |

60/60/60 m/min

(2,362/2,362/2,362 ipm) |

| Travel (X/Y/Z) |

730/730/880 mm

(28.7″/28.7″/34.6″) |

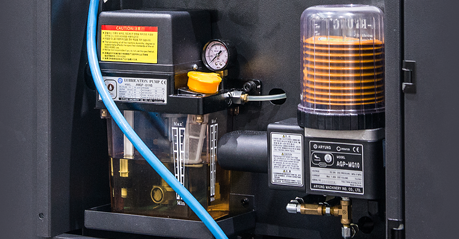

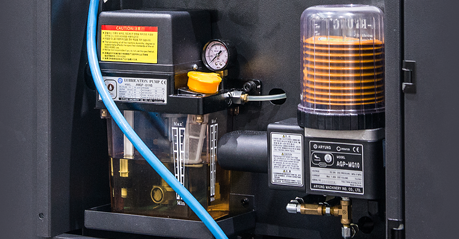

Grease Lubrication Device

- PLC control allows for timely supply of extremely small amount of grease

- System alarm (low level, line blockage)

- Oil skimmer is unnecessary

- Up to 60% reduction of annual maintenance costs compared to ordinary lubricant oil

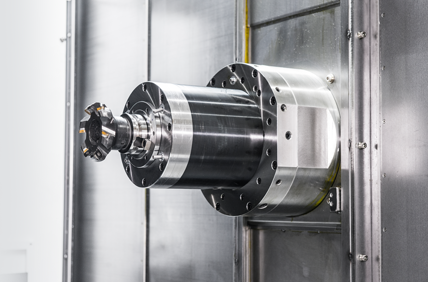

2SPINDLE

15,000r/min Built-in Spindle

By using ultra precision class angular ball bearings, fast acc/ deceleration of the main spindle is achieved. The spindle head is designed to minimize heat displacement therefore reducing heat generation and making it possible to maintain high accuracy. Also, thermal displacement can be minimized by applying oil cooling system.

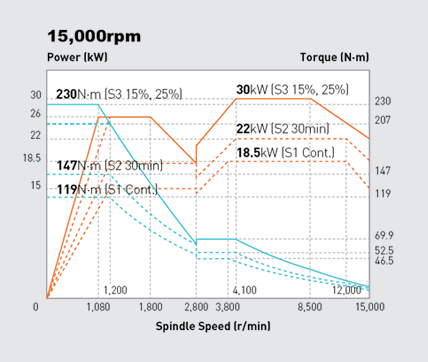

15,000 rpm

| Power (Max./Cont.) |

30/18.5 kW [40/25HP] |

| Torque (Max./Cont.) |

230/119 N·m |

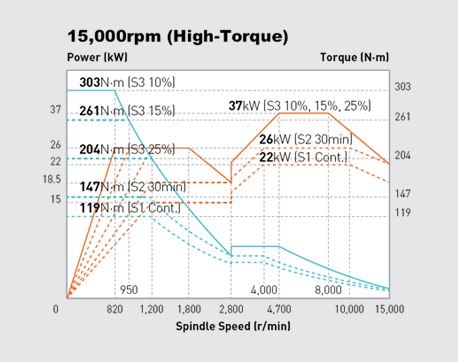

15,000 rpm (High-Torque) OPTION

| Power (Max./Cont.) |

37/22 kW [50/30HP] |

| Torque (Max./Cont.) |

303/119 N·m |

ATC & APC

Optimal Processing System for Users

1ATC & APC

40T High speed ring type magazine applied (60T : Opt.)

The HS5000 II has a ring type magazine as standard. The ring type magazine makes less noise than the existing chain type and has faster rotation of the magazine, which contributes to reduced tool exchange time and improved productivity.

60T Magazine Max Call Time : 2.9 sec

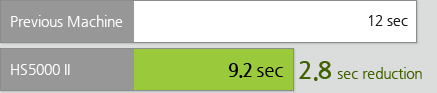

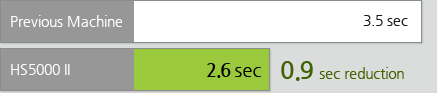

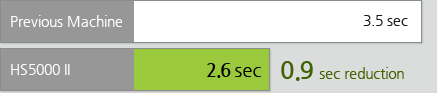

Tool Changing Time Shorten (Chip-Chip)

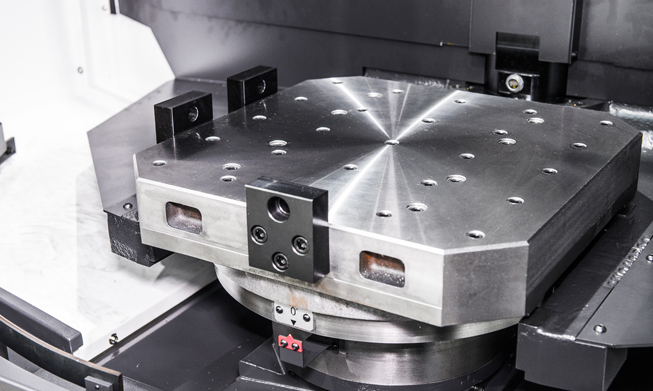

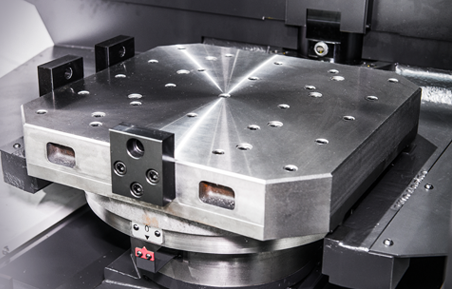

APC & Pallet

HS5000 II provides a lift rotary type APC(automatic pallet changer) as standard. The loading station pallet can be rotated and locked in 90° increments for convenient loading/unloading of workpieces.

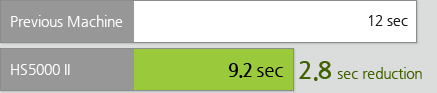

Pallet Changing Time Shorten