New Product

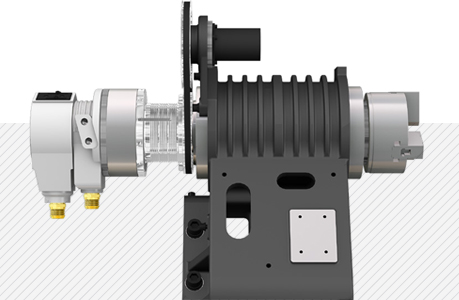

KIT4500 Gang Type CNC Turning Center

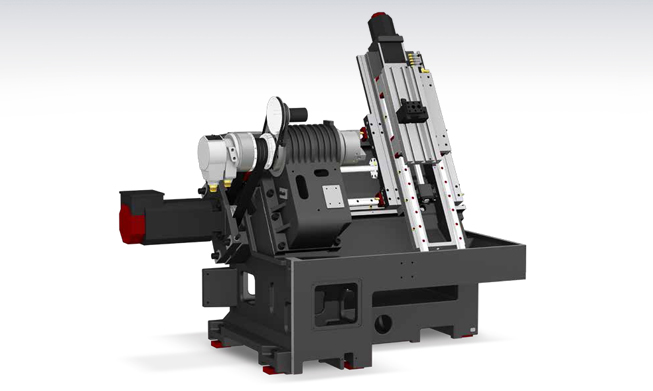

The Gang Type CNC Turning Center KIT4500, designed by Hyundai WIA with years of expertise and the latest technology, is a gang tool CNC Turning Center which maximizes productivity through high speed and high performance mechanisms.

High Speed, Rigidity and Productivity

Economical Gang Type CNC Turning center

- 60° slanted one-piece bed structure with high rigidity

- Stabilized unit structure to minimize thermal displacement

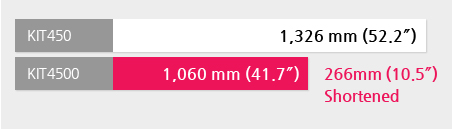

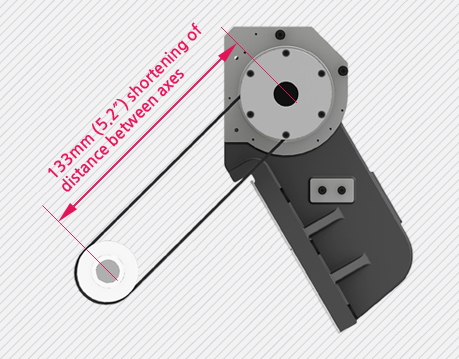

- Reduction of belt damage and spindle vibration through decrease of spindle belt length

- Optimal design for automation

- Compact design suitable for installation in restricted space

Basic Features

The Most Advanced Mechanism, Revolutionized Productivity & High Performance

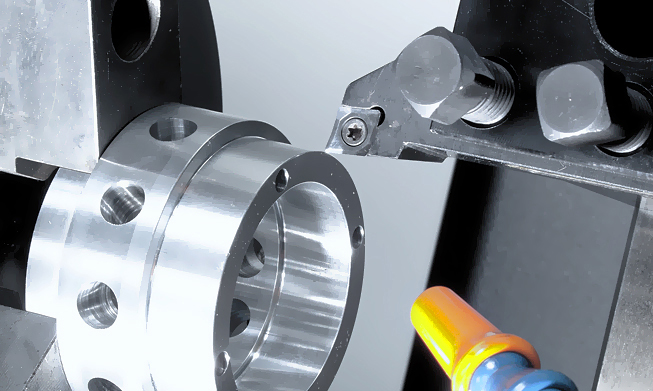

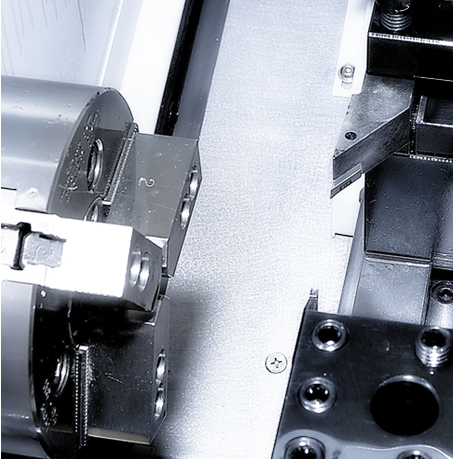

Guideway

All axes of KIT4500 is designed with LM Guides. It reduces machining noise and enhances productivity through faster traverse rate.

| Rapid Traverse Rate (X/Z axis) | 30/36 m/min (1,181/1,417 ipm) |

| Travel (X/Z axis) | 450/300 mm (17.7″/11.8″) |

| Max. Turning Dia. | Ø165 (Ø6.5″) |

| Max. Turning Length | 300 mm (11.8″) |

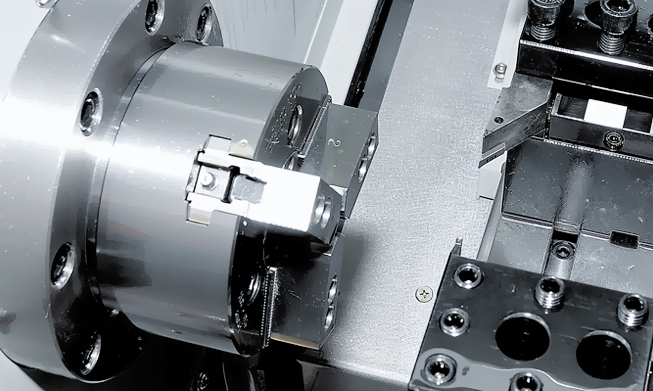

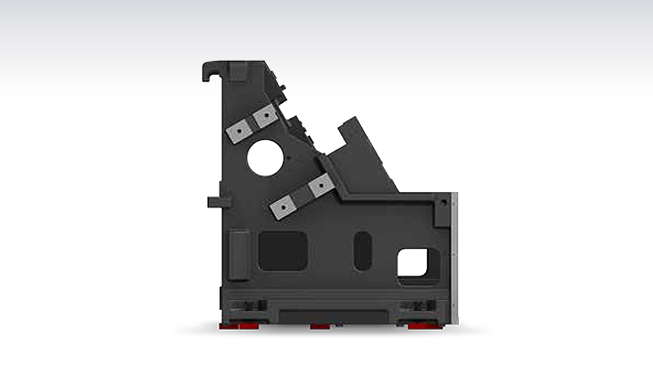

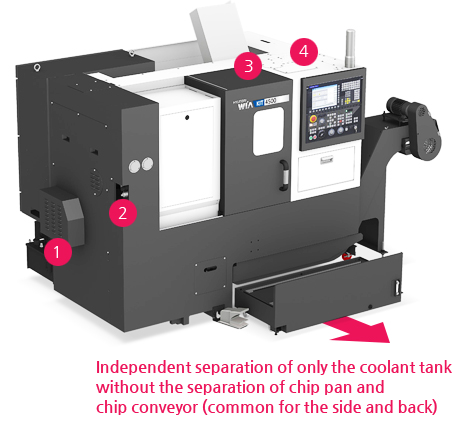

160° Slant Bed Structure

The application of 60° slant bed ensures excellent chip processing with easy access to the chuck during your tool setting for your increased convenience. Especially, thermal displacement has been greatly improved compared to that of the existing machine as the thermal expansion directions of both the spindle and table are identical according to the thermal displacement of the bed.

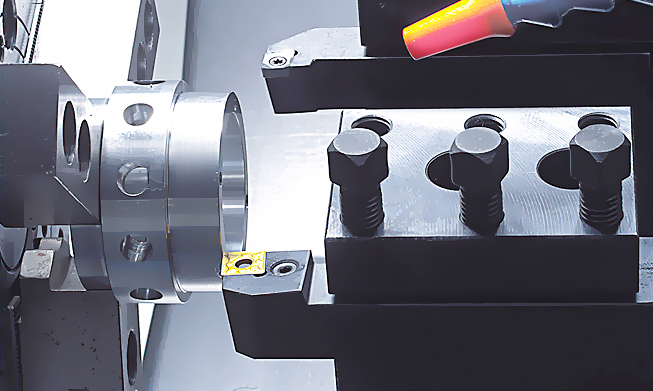

2Ball Screw

Thermal displacement on the X axis has been reduced by 50% compared to that of the existing equipment due to improvements on the carriage structure on the X axis. Especially, the supporting capability has been improved as the support bearing of ball screws is expanded from the existing 2 EA to 3 EA on the X axis.

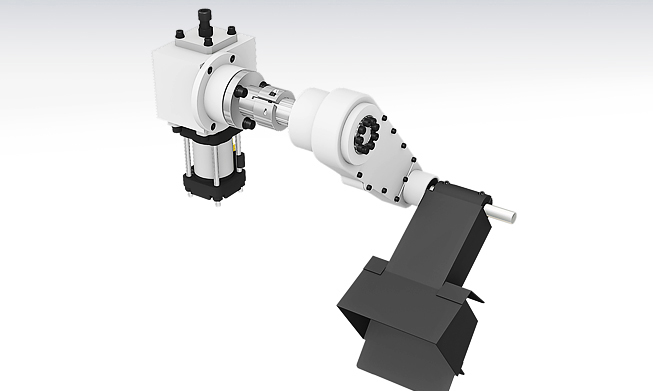

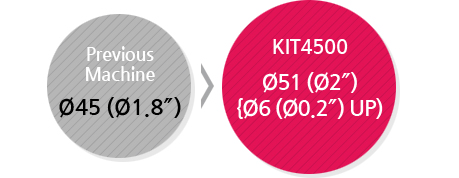

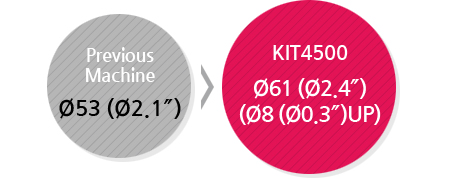

3Main Spindle

Precise machining can be done even in high speed due to the adoption of high precision angular ball bearings, and vibrations delivered to the main spindle have been minimized with the improved durability of the belt as the driving belt length on the main spindle is shortened.