New Product

XF8500 Simultaneous 5-Axis Vertical Machining Center

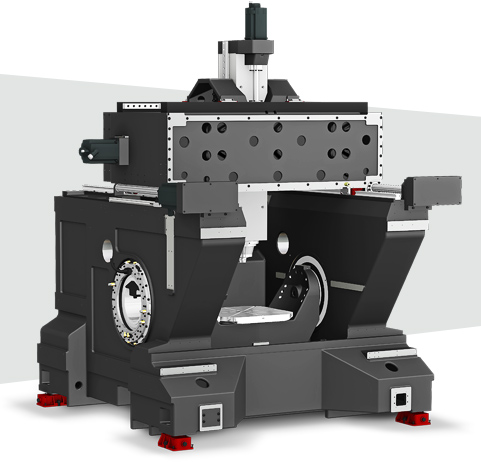

The XF8500, 5-axis vertical machining center in the world-best level, is developed by HYUNDAI WIA Europe R&D Center.

The XF8500 has realized the ultimate performance in composite machining and mold machining with its cutting-edge designed features such as the monoblock type bed structure, X/Z axis box-in-box structure, etc.

5-Axis Vertical Machining Center for composite machining and mold machining.

- High-speed & High-precision 5-Axis Machining Center for medium- and large-sized product.

- One piece column-bed structure through optimal structural analysis – Rigidity has improved by 130%

- High quality machining by design methodology that minimize vibration and thermal displacement during travel

- Linear and rotary scale are equipped as standard for the high quality of machining

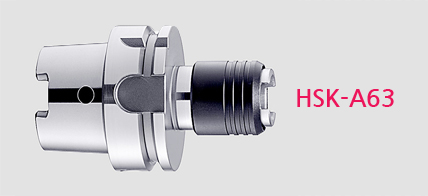

- Built-in spindle has applied for high-speed and -accuracy – Spindle displacement sensor applied as a standard

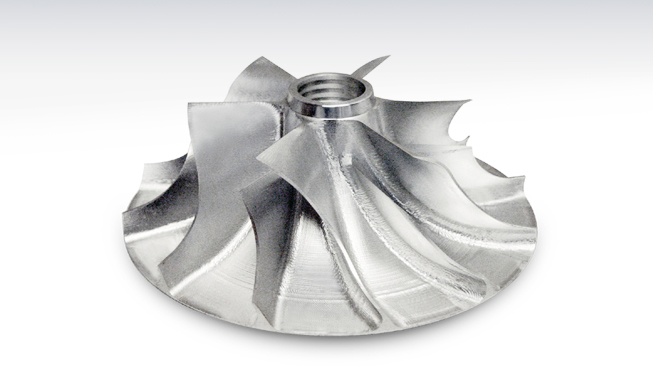

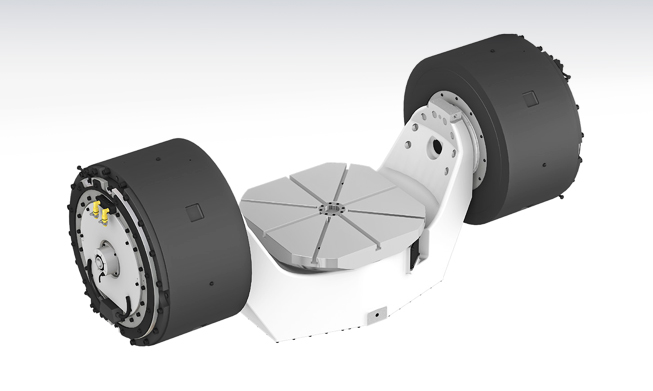

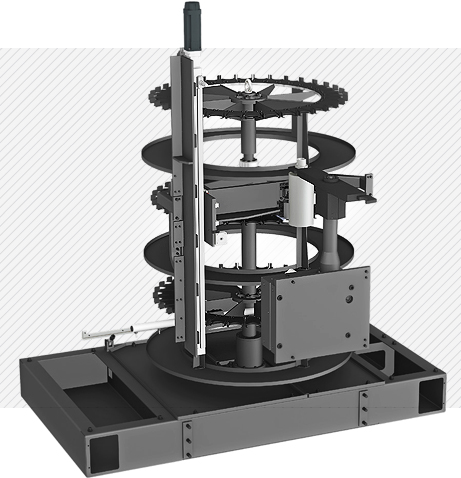

- The DDM rotary table provides simultaneous 5-axis motion which allows for the machining of complex prismatic parts.

Basic Features

High-Precision & Speed 5-Axis Vertical Machining Center

Rapid Feed Rate (X/Y/Z axis)

45/45/45 m/min (1,772/1,772/1,772 ipm)

(A/C axis)

50/100 rpm

Travel (X/Y/Z/A/C axis)

850/920/600 mm (33.4″/36.2″/23.6″), 150°/360°

Spindle Speed

9,000 r/min

Spindle Output

42/31 kW (56.3/41.6 HP)

Spindle Torque (Max./Cont.)

175/130 N.m

(129/95.9 lbf.ft)

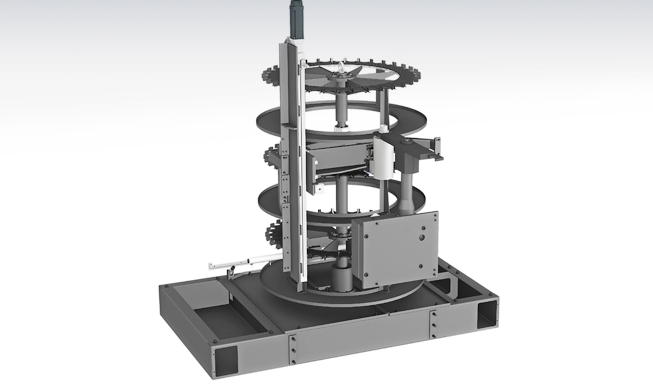

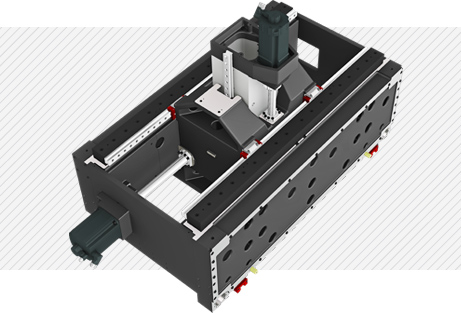

1Column / Bed All-in-One structure

XF8500 is designed with unified column-bed structure. When compared to separate structure, it has better structural stability. It demonstrates excellent performance in high quality machining with high rigidity and excellent vibration absorption.

(Monoblock Structure)

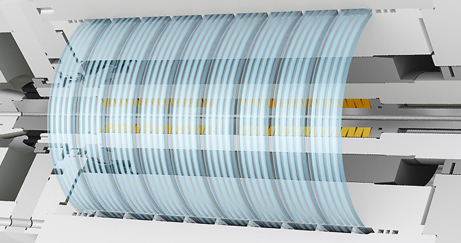

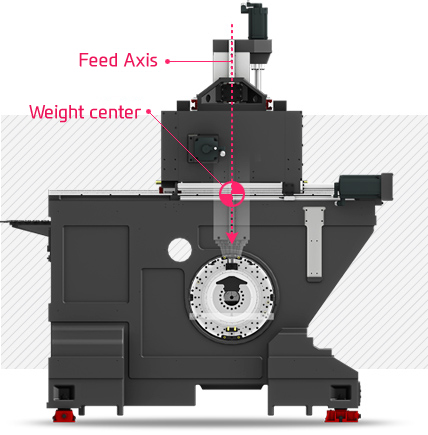

2Symmetric Structure of Z-axis

Vibration and thermal displacement during travel can be minimized by symmetric structure of Z-axis where travel axis is aligned with the weight center of spindle.

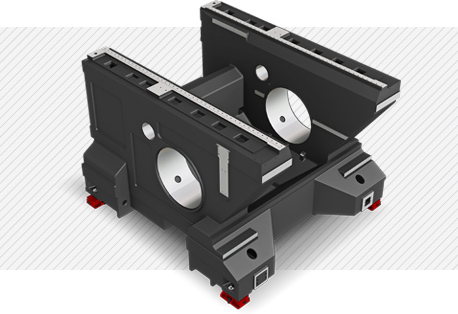

34-Way Structure on X Axis

X-axis of XF8500 has box-type saddle design with 4-way structure in a cross beam to realize improved strength and minimized thermal displacement.

Box-in-Box Structure (X/Z Axis)

The pusher(head body) in the saddle of X-axis, which surrounds the spindle cartridge, is desinged with box-in-box type. This thermal equilibrium structure helps minimize thermal deformation.