New Product

KF760BM Excellent Cutting Capability & Productivity for Mold Machining

The Vertical Machining Center KF760BM, designed by Hyundai WIA with years of expertise and the latest technology, maximizes productivity while maintaining rigidity and accuracy.

The Fastest, the Most Versatile High end Linear Machining Center

- Built-in spindle for a high-quality mold processing

- Excellent vibration absorption through box guideways in all axes

- Decrease of travel load with semi-air-floating slide way

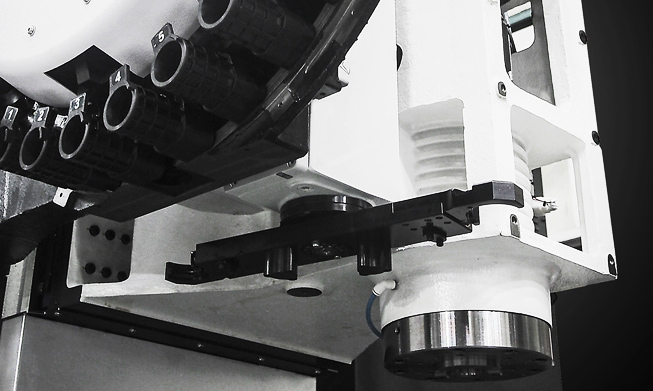

- Prevent vibration fundamentally by seperated column and magazine

- Mold pacakage for precise machining (option)

Basic Features

Excellent Cutting Capability & Productivity for Mold Machining

KF760BM

| Travel (X/Y/Z) | 1,550/760/720 mm (61″/30″/28.3″) |

| Rapid Traverse Rate (X/Y/Z) | 16/16/12 m/min (630/630/472 ipm) |

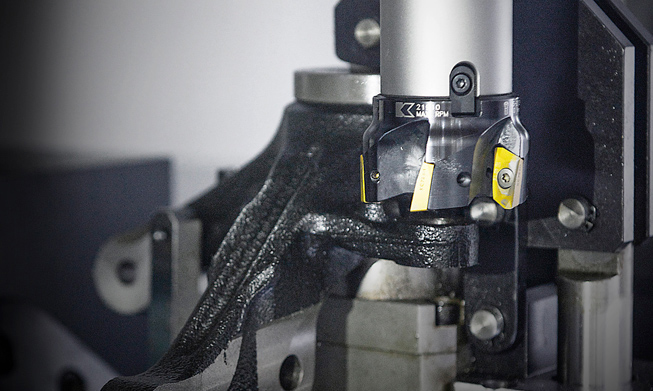

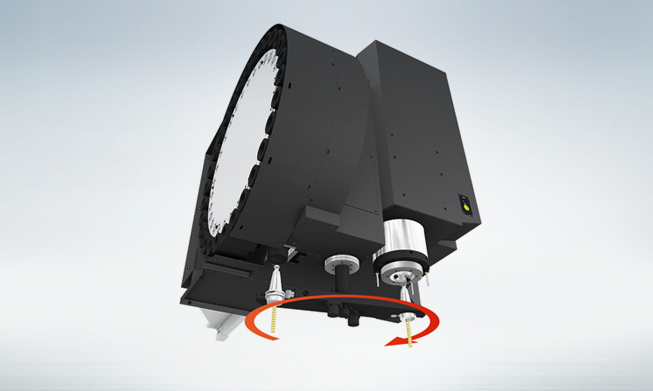

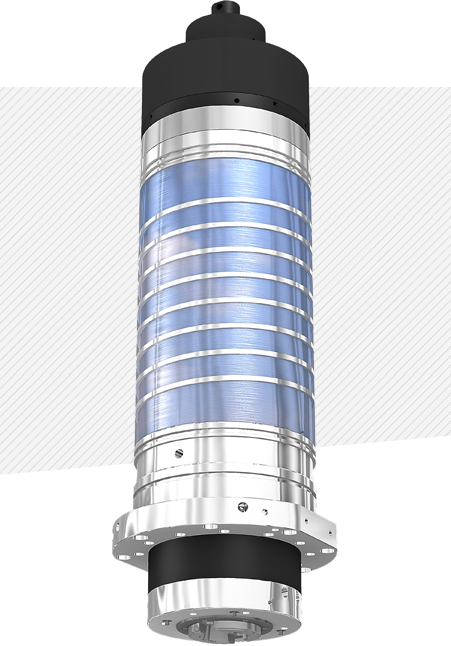

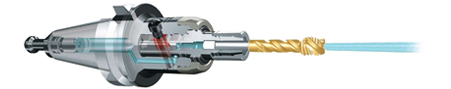

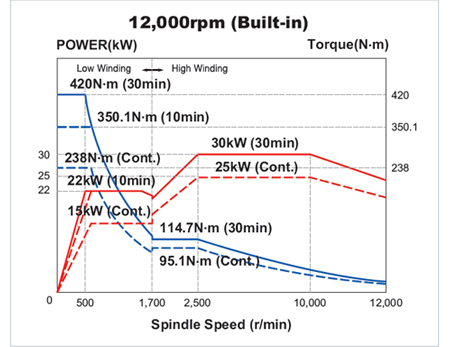

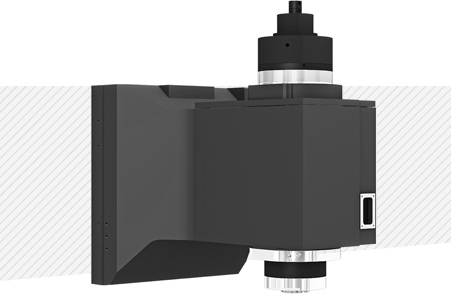

1Built-in Spindle

Designed with a built-in motor structure, the spindle achieves maximum acceleration and deceleration by suppressing vibration and heat that can occur during high-speed rotation, and maintains stable accuracy even under high-speed heavy duty cutting.

※Thermal Displacement Compensation as Standard

Enhanced Rigidity by Weight Reduction

Especially, over-hang problem is decreased due to weight reduction(10%) of main spindle compare to the previous model to achieve high-quality mold machining.

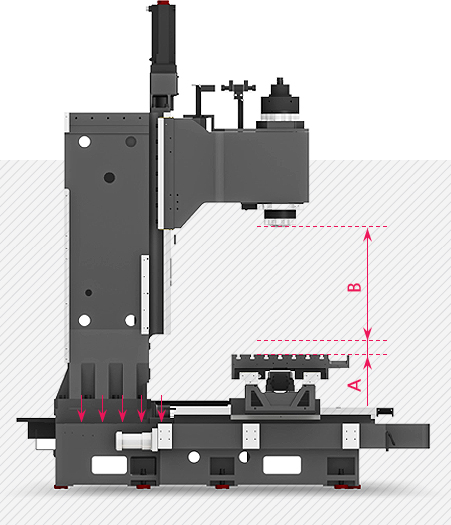

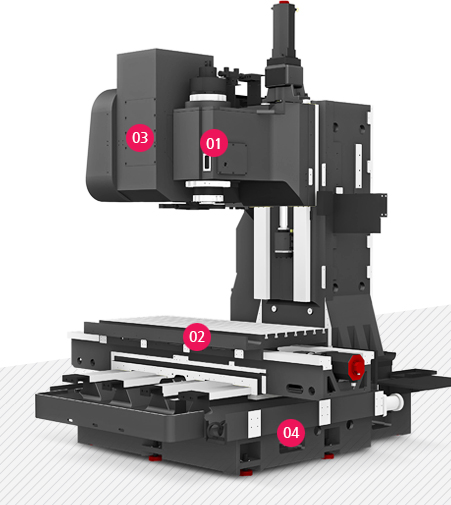

2Table

Compared to competitive machines, the KF760BM has a large working capacity to make setup easier and provide convenience to the operator.

| Model | KF760BM |

|---|---|

| Size | 1,800×700 mm (70.9″x27.6″) |

| Load Capacity | 2,000 kg (4,409 lb) |

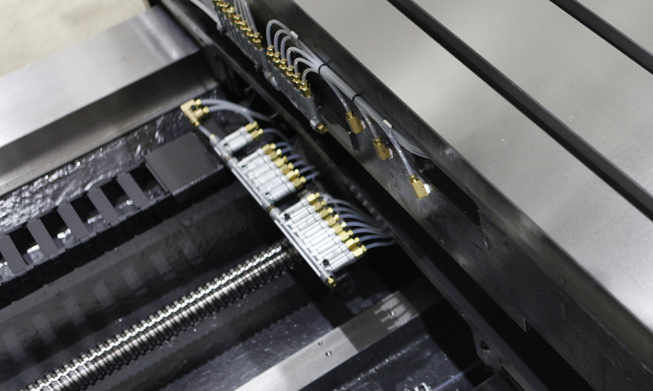

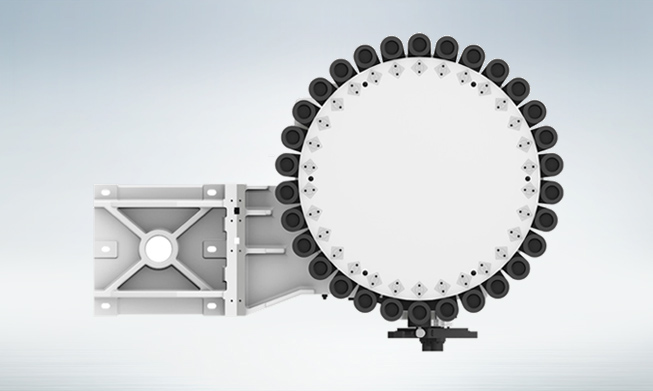

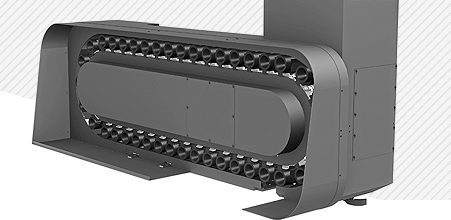

3Magazine

Magazine of KF760BM is separated from the main column to aviod magazine vibration which can affect precise mold machining.

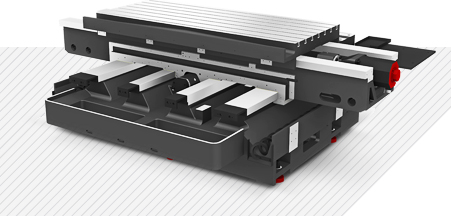

4Optimal Structural Analysis

KF760BM is designed to have optimal structure through Hyundai WIA's unique structural analysis.In particular, enhancement of bed and column's rigidity makes excellent performance even in heavy duty cutting.

Increased Rigidity through Structural Analysis

Compared to the previous model

X Axis : 115% UP Y Axis : 164% UP Z Axis : 162% UP