Vorstellung neuer Produkte

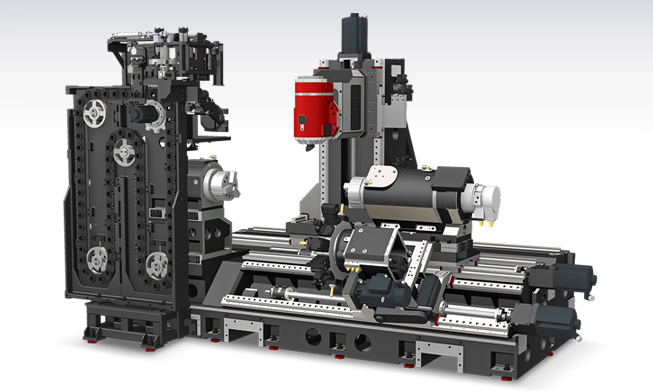

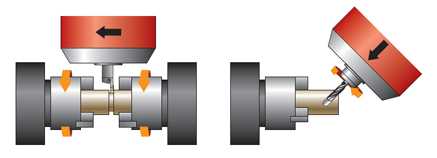

KM2600MTTS Process-intensive 9-axis Multi-tasking Machine

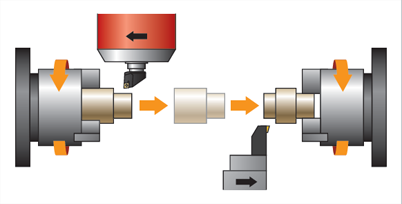

The multitasking machine KM2600MTTS,

designed by HYUNDAI WIA with years of expertise and the latest technology, is designed to maximize productivity by utilizing twin spindles and mill head.

High-rigidity Construction with High Aging Resistance

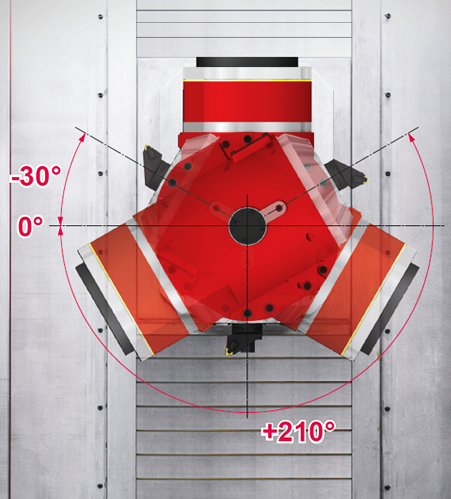

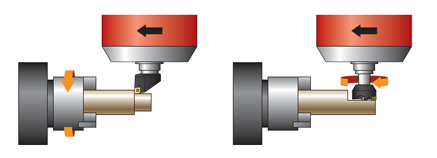

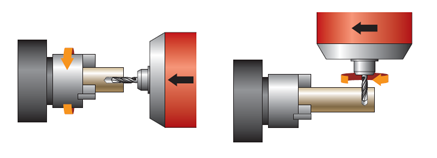

- The adoption of a milling head with a built-in B axis (0.0001control) enables the operator to perform turning and milling works in perfect harmony.

- The highly rigid Y-axis structure makes it possible to process diverse shapes.

- Application of CAPTO C6 tool for high speed complex machining

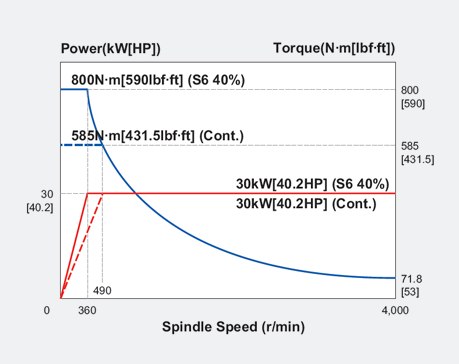

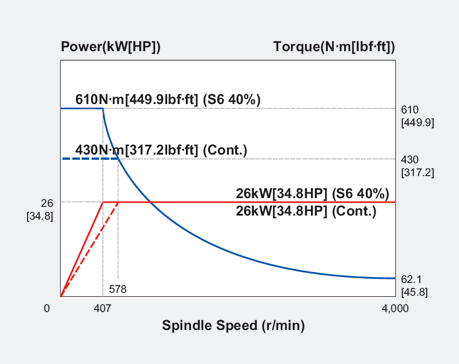

- The model features built-in main & sub-spindles with high output and high torque.

Basic Features

High Precision & Heavy Duty Cutting Y-axis CNC Turning Center

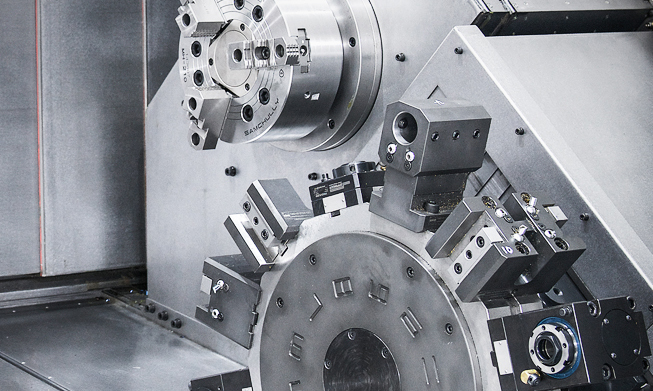

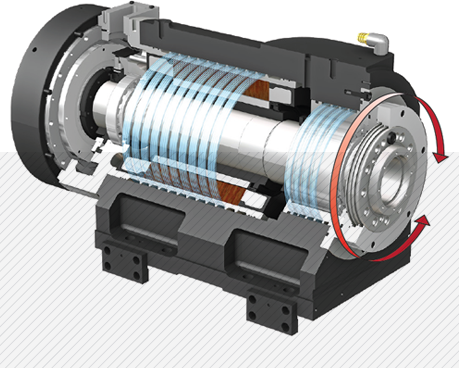

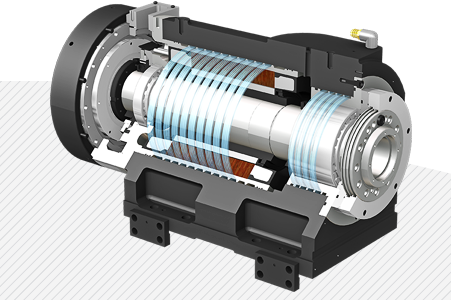

1Built-In 10″ Main & Sub Spindle

The built-in 4,000rpm-class spindle minimizes vibration to allow machining of the highest precision.

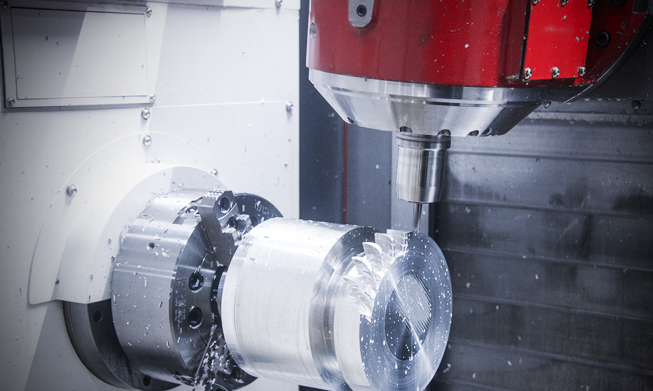

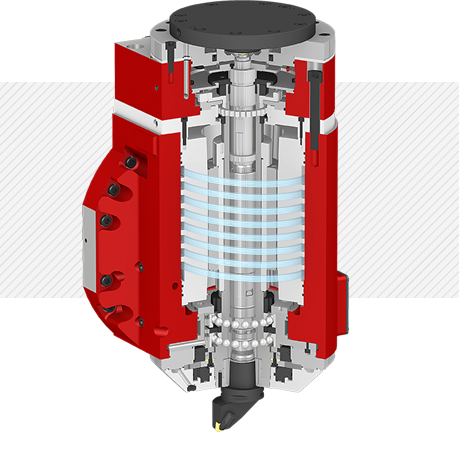

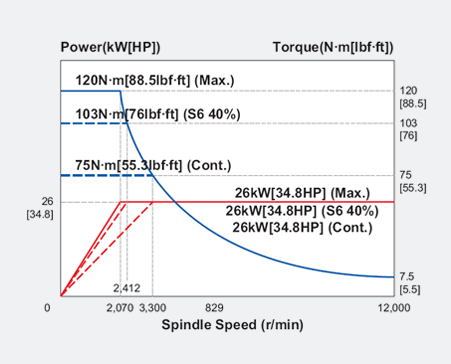

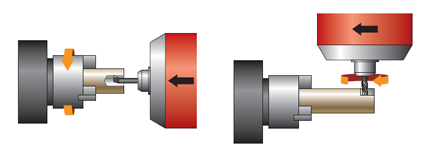

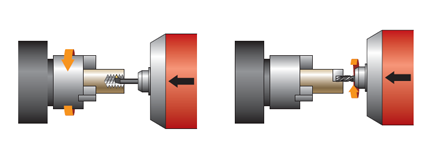

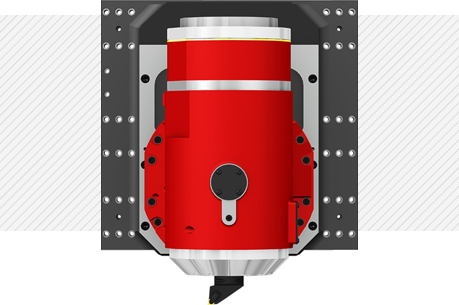

2Mill Head

The mill head of KM2600MTTS, where the b-axis control can be done, is mounted with a high-resolution encoder having a DDM (Direct Drive Motor) and 0.0001° to secure high positioning precision. This shows the highest machining perfomance among the same class.

<12,000 r/min>

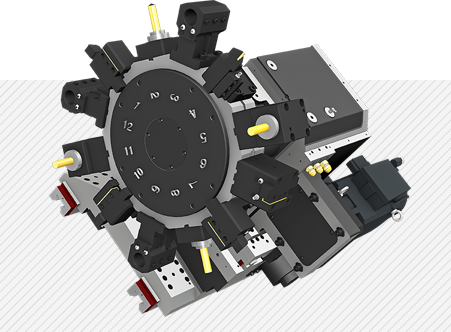

3BMT Lower Turret

The lower turret ensures the high-speed machining of complicated shapes in precision only with the one-time setting of an object to be machined with the mill head and complex machining.

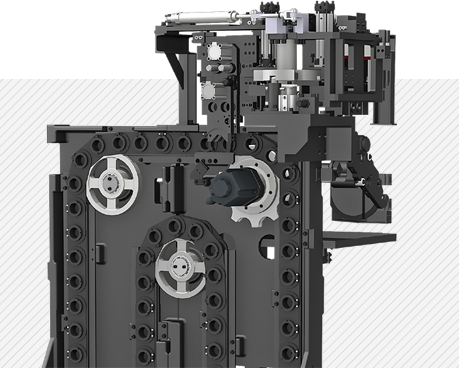

4ATC & Magazine

The installation of magazine on the front provides the efficient tool exchange and tool setting. Magazine with chain driving method provides 36 tools as a standard, and 72 tools as an option.

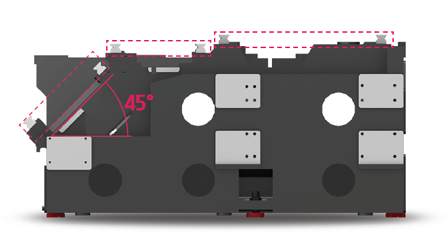

5High Precision, High Rigidity Bed Structure

Z-axis in a 3-way structure is applied to remove any interference in conveyance between the tool station and 2nd spindle. Design in 45° slant ensures that cutting chips and cutting oil are discharged smoothly and both high strength and high precision can be maintained.

Especially, the bed is analyzed in the FEM method to minimize factors that can be generated in the machining, such as thermal deformation, vibration, etc.