Vorstellung neuer Produkte

HS6300+PLS Hyundai WIA's Pallet Line System

is a highly advanced automation system equipped with multi-level pallet racks.

Hyundai WIA PLS is an unmanned automation system for horizontal machining centers with two-storied pallet stackers to achieve a reasonable installation area.

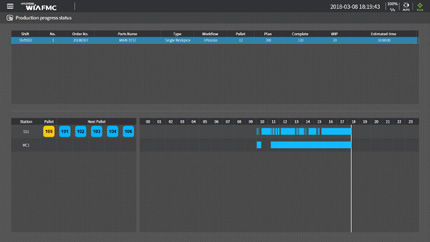

Especially, it contributes to productivity improvement by easy and efficient system operation to flexibly respond to changes in production volume.

High Level of Automation System

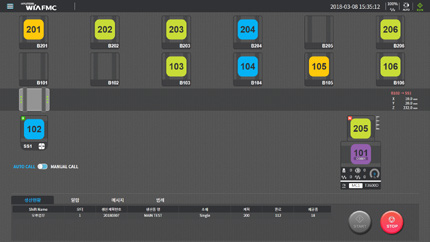

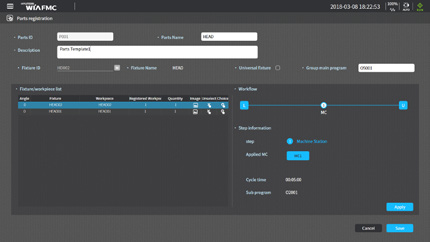

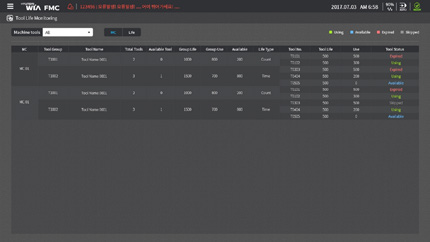

- High Level of Automation System (PLS : Pallet Line System)

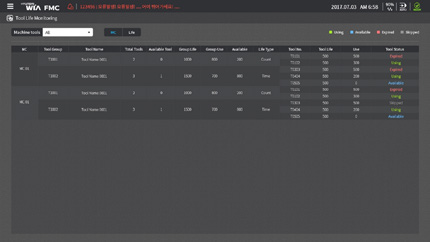

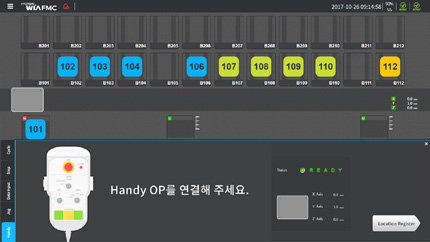

- Easy Operation & Excellent Performance (PALLEX : PLS operation software)

PLS

Hyundai WIA's Pallet Line System

PLS (Pallet Line System)

| Pallet Size mm(in) |

Ø500 (Ø19.7″) | Ø630 (Ø24.8″) |

|---|---|---|

| Load Capacity kg(lb) |

800 (1,764) | 1,200 (2,646) |

| Max. Processing Dia mm(in) |

Ø800 (31.5″) | Ø1,050 (41.3″) |

| Max. Processing Height mm(in) |

980 (38.6″) | 1,350 (53.1″) |

| No. of Pallet EA |

12~72[81] | |

| No. of Loading Station EA |

1~4 | |

| No. of Machine Tools EA |

1~7[10] | |

[ ] : Prior Consultation

PLS (Pallet Line System)

| Number of Tools EA |

195, 240, 300, 360 |

|---|---|

| Driving Method (U/V-Axis) - |

Servo |

| Tool Selection Method - |

Fixed |

| Max. Tool Dia. mm(in) |

Ø75/Ø140 (3″/5.5″) |

| Max. Tool Length mm(in) |

450 (17.7) |

| Max. Tool Weight kg(lb) |

10 (22) |