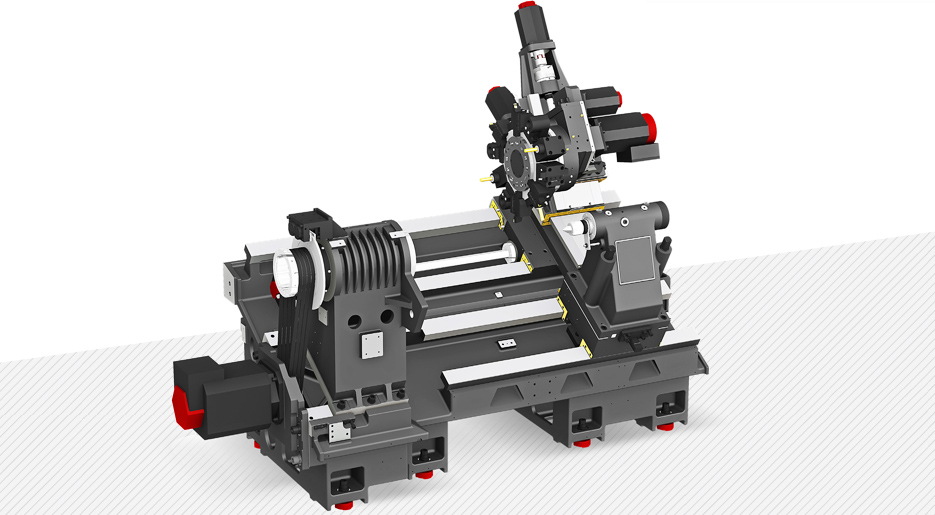

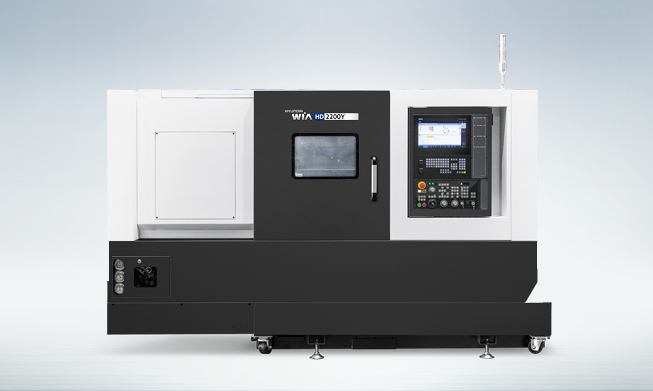

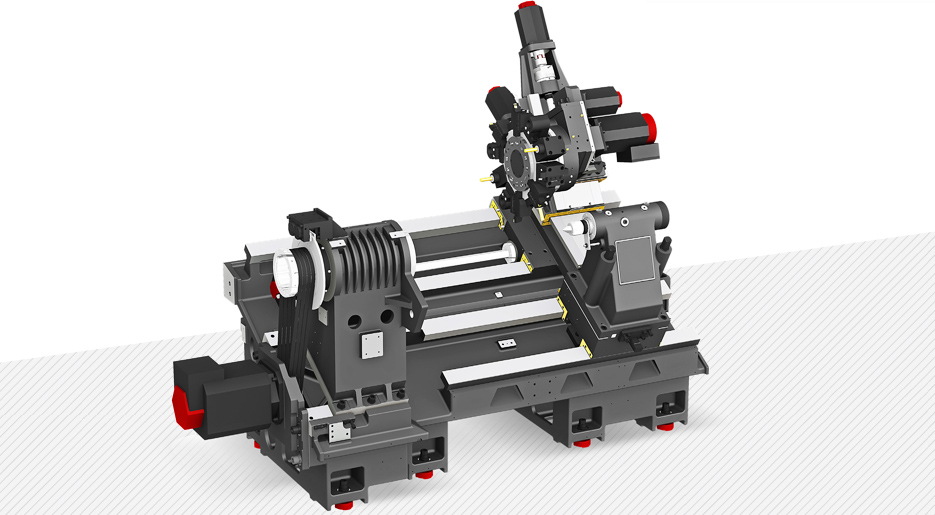

HD-SY Series Y-axis Turning Center

Hyundai Wia, one of the largest machine tool makers in Korea, used its accumulated know-how and latest technology to develop the HD-Y Series, which delivers high-performance, high heavy cutting capability, and maximum productivity concurrently.

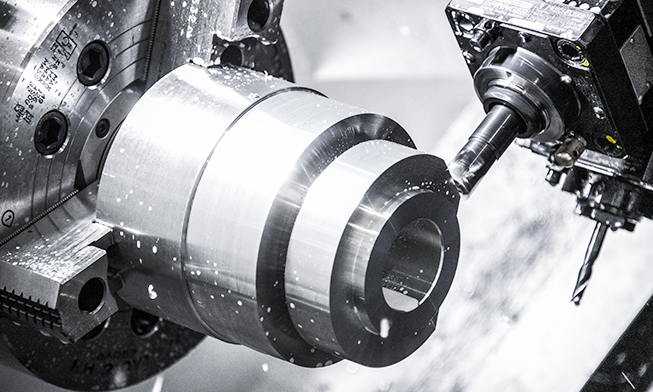

Y-axis CNC Turning Center with Highly Reliable Box Guideways

- Box guideways for enhancement of cutting capability

- Minimized thermal displacement through stabilized machine component

- Complex machining is possible with BMT55P turret transferred by wedge type Y-axis

Basic Features

High Precision & Heavy Duty Cutting Y-axis CNC Turning Center

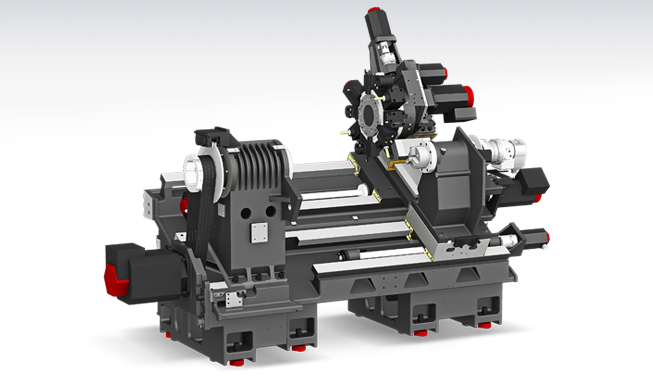

1Optimal Structural Analysis

Structural analysis was applied to the design of the machine to increase the tool post body and reduce the machine’s height so as to maintain the bed’s dynamic rigidity even during heavy-duty cutting.

In addition, the HD-Y Series bed slope is pitched at 30 degrees to ensure more stable machining.

Integrated Coolant Tank

The structure is designed with the coolant tank installed at the bed front for improved convenience. Chips can be removed from the right side of the machine.

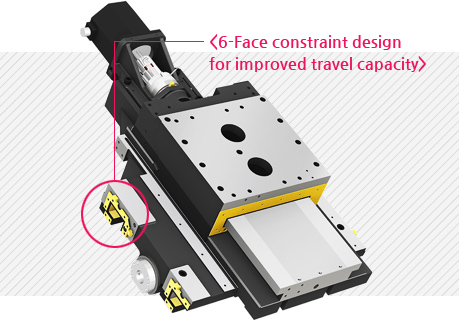

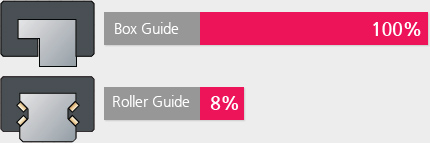

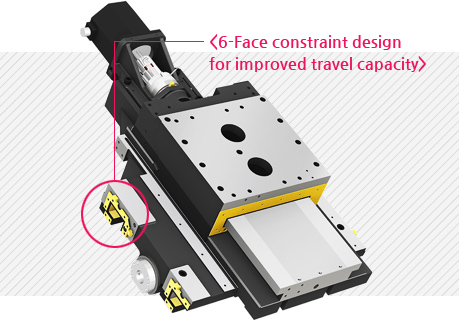

2Box Guideway on All Axes

With the mounting of box guideways on all axes, the machine offers excellent vibration absorption even against during heavy-duty cutting, enabling high-quality machining.

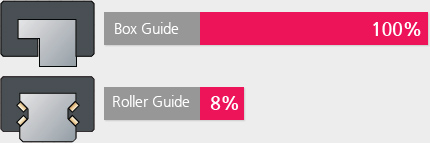

Comparing Damping Values

| Rapid Traverse Rate (X/Y/Z axis) |

24/10/30 mm (944/394/1,181) |

| Travel (X/Y/Z axis) |

215/110/680 m/min (8.5″/4.3″/26.8″) |

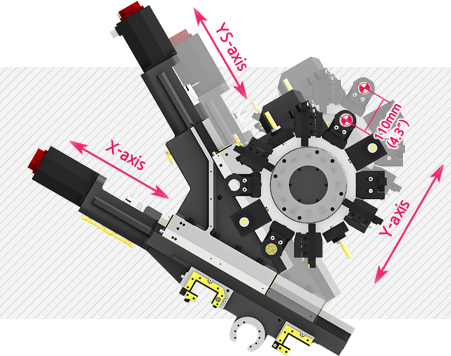

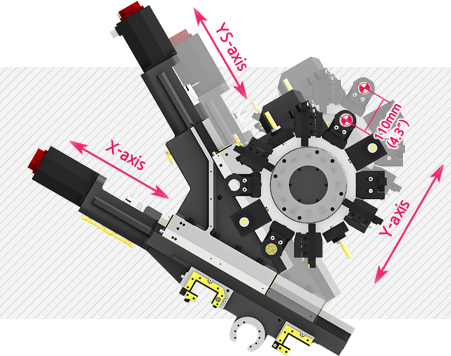

3Wedge Type Y-axis Structure

The HD-Y Series is designed with a wedge type Y-axis that is transferred by the simultaneous operation of the Ys-axis and the X-axis. In addtion, excellent rigidity makes possible to perform superb quality when machining a heavy-duty cutting.

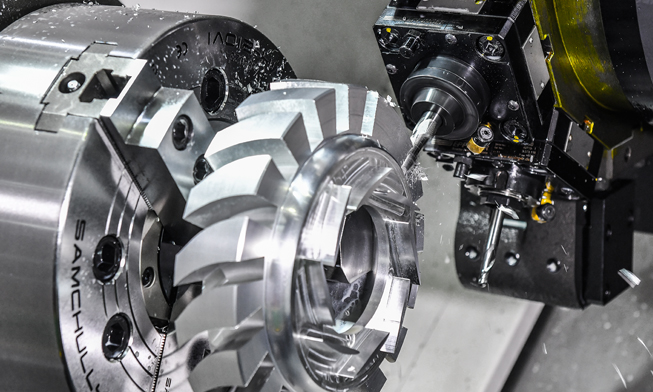

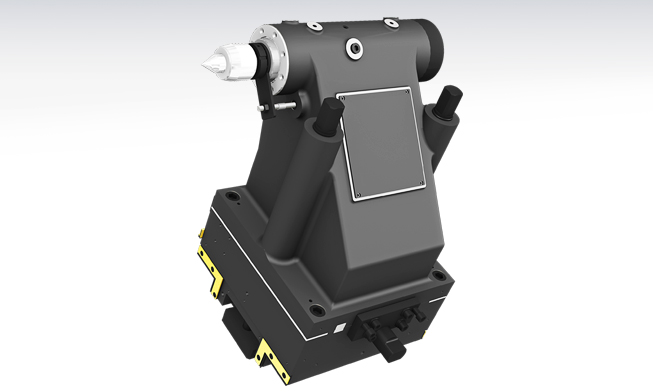

Mill Turret (BMT55P Turret)

The large BMT55P turret enables the HD-Y Series to perform high accuracy milling operations in a single set-up.

The BMT turret is driven by a high torque servo motor with a 0.2 second indexing time(1 Step) in either direction.

| Max. Speed |

6,000 r/min |

| Max. Output |

5.5 kW(7.4HP) |

| Max. Torque |

53 N·m(39lbf·ft) |

4HD-SY Series Line-Up

● : Standard ○ : Option

Spindle and Turret

Long Lasting, High Accuracy & Excellent Performance CNC Turning Center

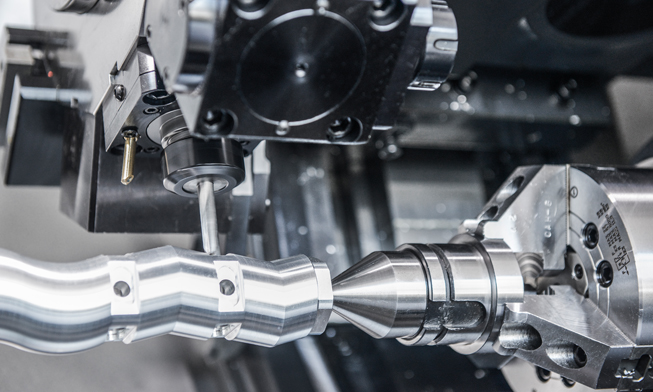

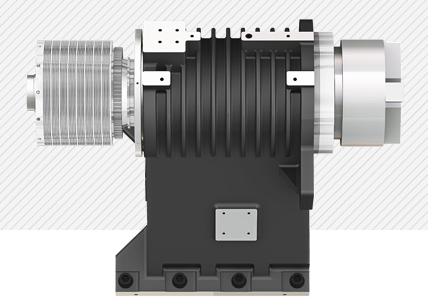

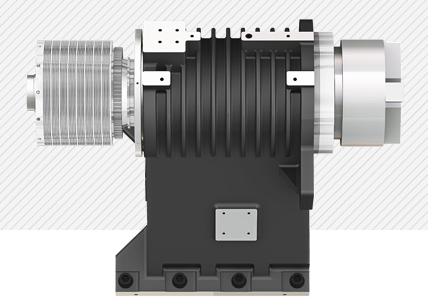

1Spindle for Heavy Cutting

The main spindle is designed with the same structure often found in larger sized machines. The combination of taper roller bearings and angular contact ball bearings leads to excellent heavy duty cutting performance.

Also, machining performance is enhanced by applying ribstar belt to minimize noise and belt slipping problems. The spindle is designed with a labyrinth structure to minimize possible bearing damage from coolant and to improve machining stability.

C-Axis Control

C-axis of HD-Y Series can be controlled to 0.001° which makes it possible to process various shapes.

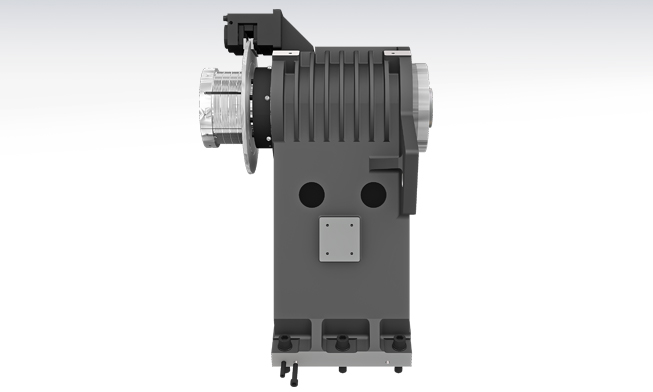

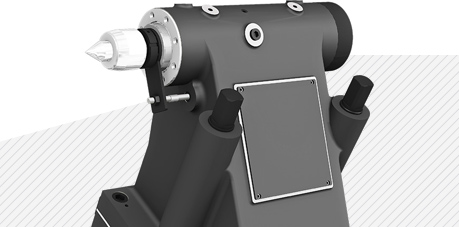

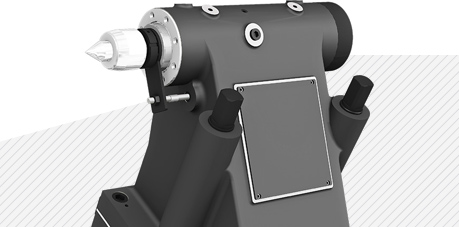

2Tail Stock

Tailstock enables stable machining of high quality products where quill travels up to120mm (4.7″).

| Quill Type |

MT#4 |

| Quill Dia. |

Ø80 mm (Ø3.1″) |

| Quill Travel |

120 mm (4.7″) |

| Travel |

680 mm (26.8″) |

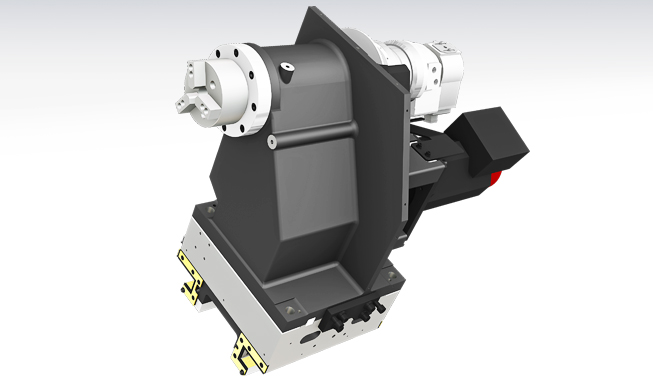

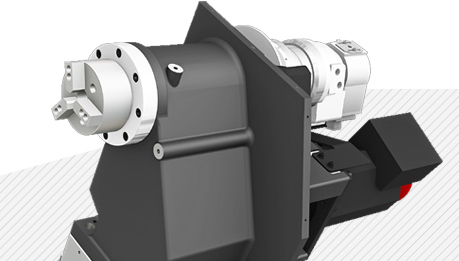

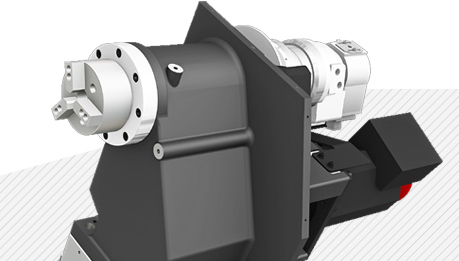

3Sub Spindle (‘SY’ Type)

The Belt-type sub spindle is designed to minimize thermal displacement during the continuous machining, offering from the heavy-duty cutting to the high-speed machining.

| HD2200SY/2600SY |

5″(6,000 r/min) |

| HD3100SYA/3100SY |

6″(4,500 r/min) |

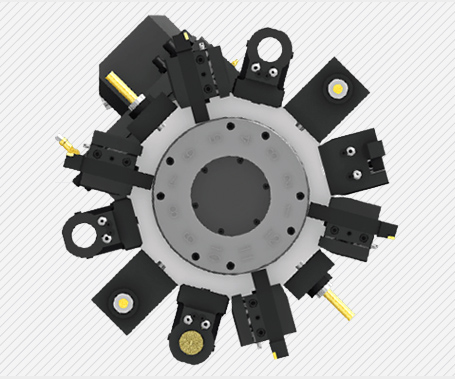

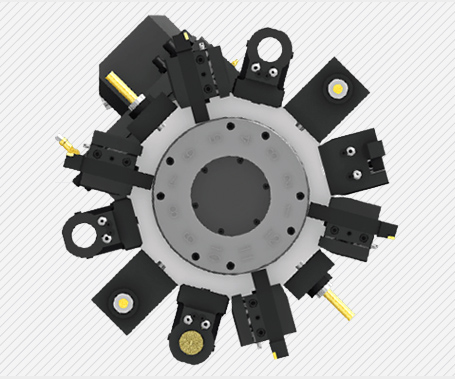

4BMT Turret (Mill Turret)

The BMT turret secures the tool with four bolts and key on the tool mounting surface of the turret, making it possible to powerfully fix the tool, ensuring high reliability in rigidity and precision.

Mill Tool Holder

Machining capability has increased with the addition of straight milling head tool holder, which can machine workpieces from the side, and angular milling head tool holder, which can perform I.D. operations.

| STRAIGHT MILLING HEAD |

ANGULAR MILLING HEAD |

|

|

BMT 55P (HD2200Y/SY | HD2600Y/SY)

| Speed (rpm) |

6,000 r/min |

| Collet size |

Ø16 (Ø5/8″){ER25} |

| Indexing Time |

0.2 sec/step |

BMT 65P (HD3100YA/SYA | HD3100Y/SY)

| Speed (rpm) |

5,000 r/min |

| Collet size |

Ø25 (Ø1″){ER32} |

| Indexing Time |

0.2 sec/step |

FANUC 0i-PLUS

Touch-type 15 ″ large monitor controller maximizes customer convenience / productivity

Standard Touch 15 ″ Large Monitor

- - Standard AICC 200 Block.

- - Standard Smart Guide-i

- - Standard machining condition selection function

15″ Touch-type Monitor as a Standard

| Smart Machine Control |

Fast Cycle Time Technology |

| Fine Surface Technology |

| Conversational Program |

Smart Guide-i |

| i-HMI |

Machining-aid Function Part Program |

| AI Contour Control |

AICC-2 (200 blocks look-ahead) |

| Smooth Tolerance Control |

0.1 ㎛ command and specify tolerance |

| Jerk Control |

Diminished vibration by controlling acceleration speed |

| Machining Condition Selection |

Designated machining level based on speed & quality |

| Machining Quality Control Function |

Smooth Tolerance+ integrated support |

| Part Program Storage |

5120M (2MB) |

| No. of Registerable Programs |

1000 EA |