New Product

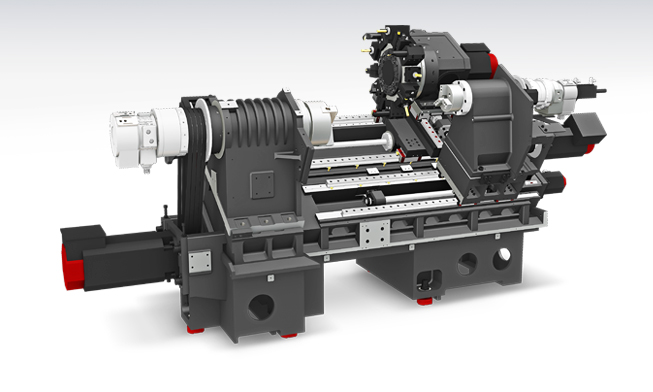

SE2200 SeriesHigh Speed, Rigidity and Productivity CNC Turning Center for next generation

The CNC Turning Center SE Series, designed with HYUNDAI WIA's engineering expertise to maximize productivity by enhancing rigidity and accuracy of machining.

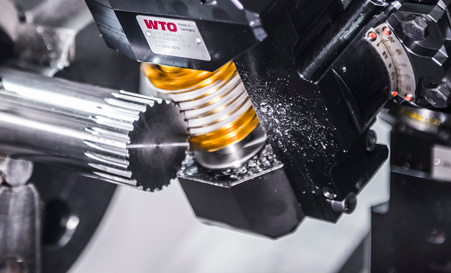

Excellent Machining Performance, Y-axis CNC Turning Center

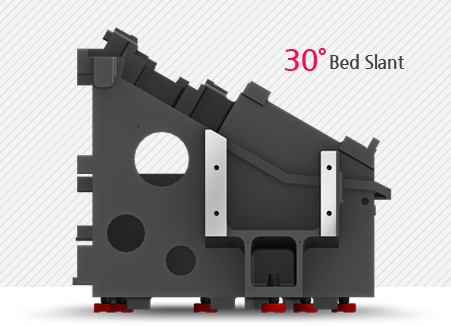

- 30° slanted one-piece bed structure with high rigidity

- Compact product size allows installation in small areas

- Improved user convenience by applying the latest controller of FANUC

- Ensured high-rigidity applying Roller guideway on all axes (X/Z-axis: 30/36m/min)

- Prepared user-oriented lineup including long-bed, mill turret and sub-spindle

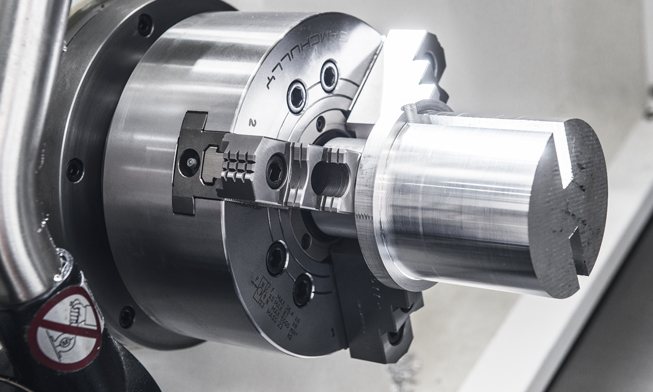

- Integrated processing through synchronized control of Main/Sub spindle

- Ergonomic design for convenient access to chuck and tool

- Stabilized unit structure to minimize thermal displacement

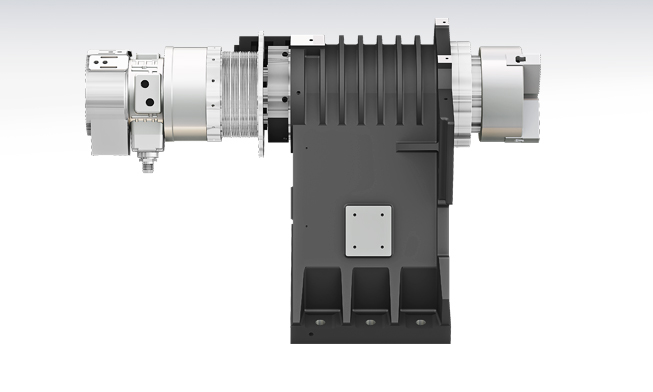

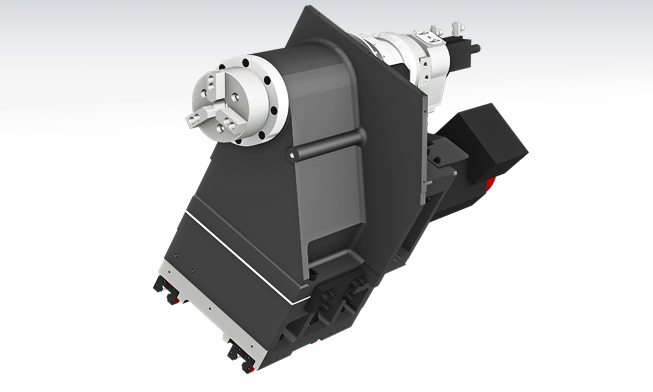

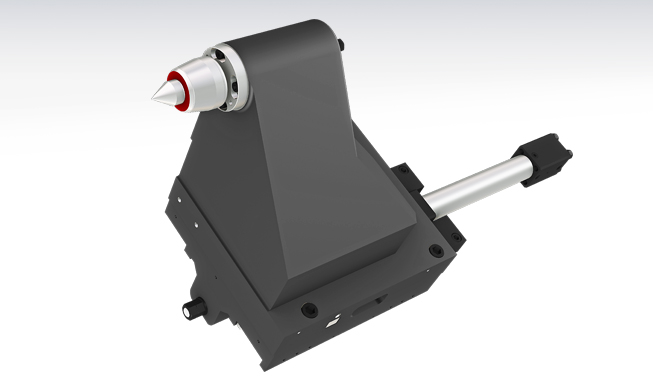

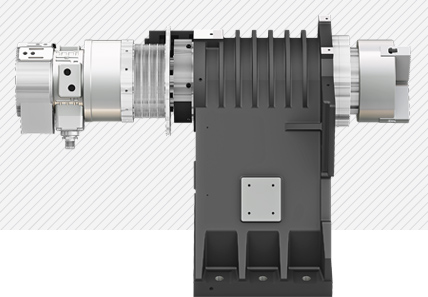

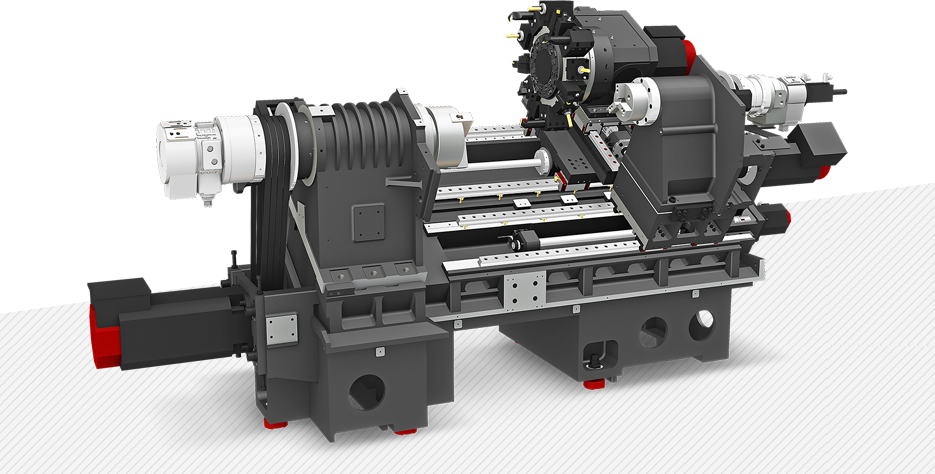

Basic Structure

The Best Productivity 6″ / 8″ / 10″ Compact CNC Turning Center

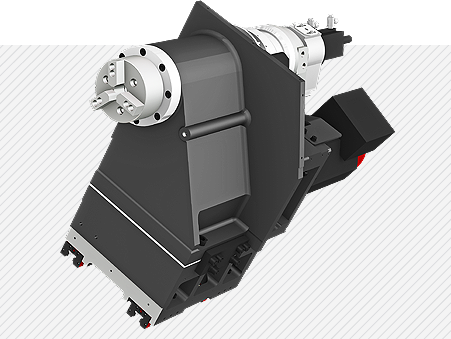

1All-In-One Type Of Bed

Structural analysis was applied to the design of the machine to increase the tool post body and reduce the machine’s height so as to maintain the bed’s dynamic rigidity even during high-speed machining. In addition, the SE Series bed slope is pitched at 30 degrees to ensure more stable machining.

Enhanced Vibration Absorption

Thanks To Increased Ground Area

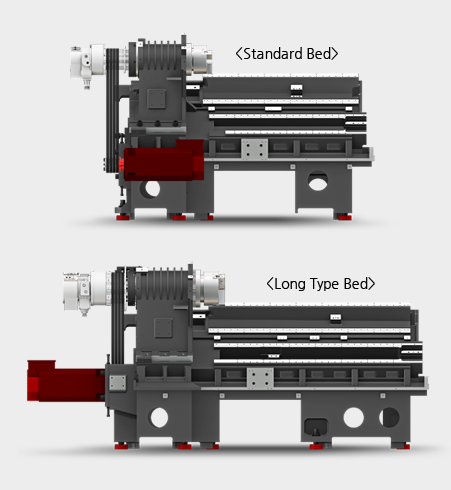

Floor Space (L×W)

| Standard Bed | 2,120×1,610 mm (83.5″×63.4″) |

| Long Type Bed | 2,970×1,610 mm (116.9″×63.4″) |

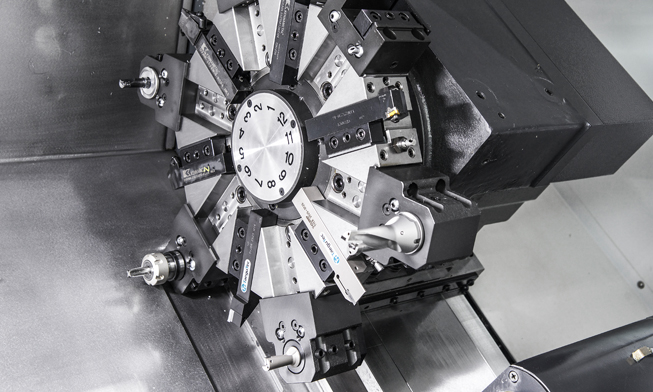

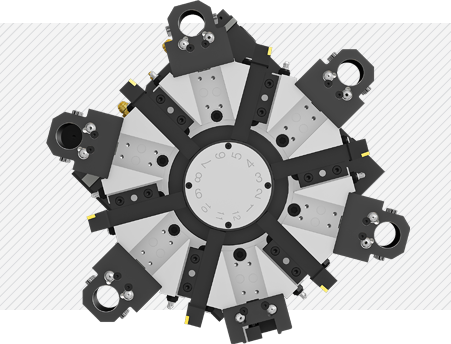

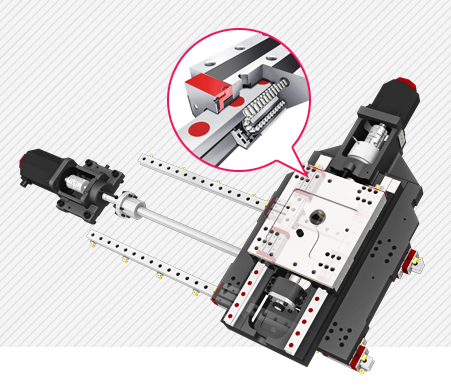

2High-Speed Roller LM Guideway

Linear roller guideways are applied to reduce non-cutting time and bring high rigidity.

Rigidity Has Increased 30% Compared

To The Ball Bearing LM Guide

| Rapid Traverse Rate (X/Z) | 30/36 m/min (1,181/1,417 ipm) |

|

| Travel (X/Z) | Standard Bed | 210/340 mm (8.3″/13.4″) |

| Long Type Bed | 210/560 mm (8.3″/22″) | |

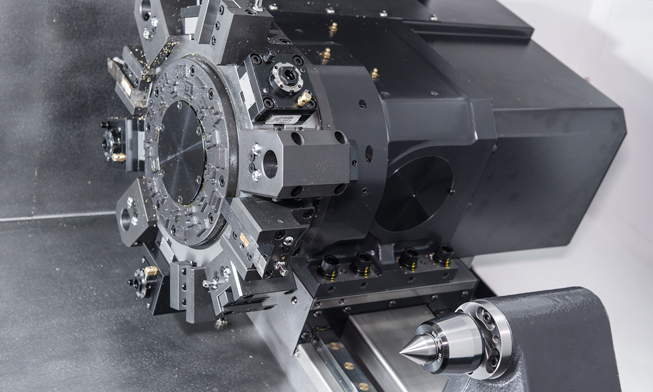

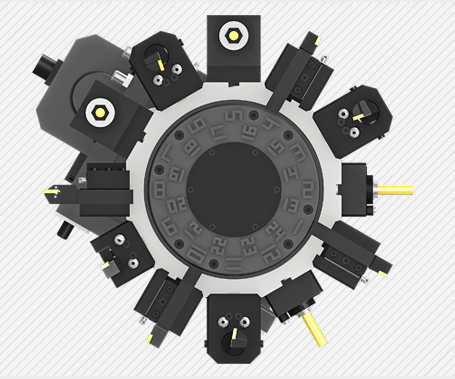

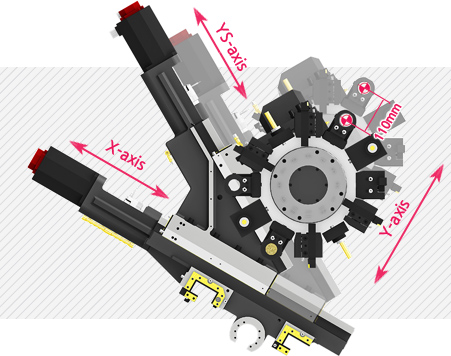

3Wedge Type Y-Axis Structure

Y-axis additional type is designed with a wedge type Y-axis that is transferred by the simultaneous operation of the Ys-axis and the X-axis. In addtion, excellent rigidity makes it possible to perform superb quality when machining a high-accuracy machining.

| Y-axis Rapid Traverse Rate | 10 m/min (394 ipm) |

| Y-axis Travel | 110 {±55} mm (4.3″) |

4SE Series Line-Up

| Model | Chuck | Bed Type | Turret | T/S | |||||

|---|---|---|---|---|---|---|---|---|---|

| 6″ | 8″ | 10″ | Sub : 5″ | Standard | Long | Standard | BMT45 | MT#4 | |

| SE2200A | ● | ● | ● | ○ | |||||

| SE2200LA | ● | ● | ● | ● | |||||

| SE2200MA | ● | ● | ● | ○ | |||||

| SE2200LMA | ● | ● | ● | ● | |||||

| SE2200LMSA | ● | ● | ● | ● | |||||

| SE2200 | ● | ● | ● | ○ | |||||

| SE2200L | ● | ● | ● | ● | |||||

| SE2200M | ● | ● | ● | ○ | |||||

| SE2200LM | ● | ● | ● | ● | |||||

| SE2200LMS | ● | ● | ● | ● | |||||

| SE2200LC | ● | ● | ● | ● | |||||

| SE2200LMC | ● | ● | ● | ● | |||||

| SE2200LMSC | ● | ● | ● | ● | |||||

| SE2200YA | ● | ● | ● | ○ | |||||

| SE2200LYA | ● | ● | ● | ● | |||||

| SE2200LSYA | ● | ● | ● | ● | |||||

| SE2200Y | ● | ● | ● | ○ | |||||

| SE2200SLY | ● | ● | ● | ● | |||||

| SE2200SLSY | ● | ● | ● | ● | |||||

● : Standard ○ : Option

SE2200 Series Video