New Product

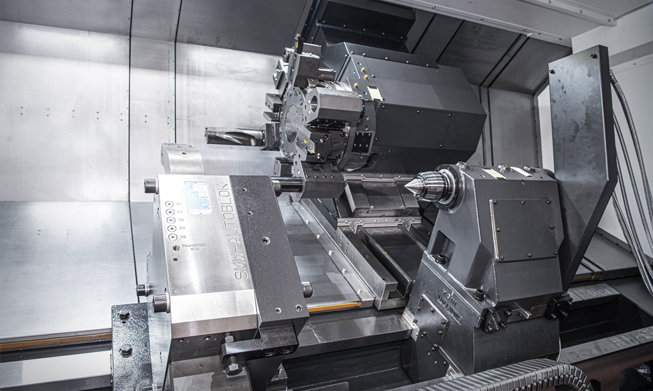

L5100LY Heavy-Duty Cutting, Large Work Capacity, CNC Turning Center

The L5100LY, Y-axis CNC turning center designed with HYUNDAI WIA's engineering expertise to maximize productivity by enhancing rigidity and accuracy of machining.

Heavy Duty, Large Capacity, Y-axis CNC Turning Center

- Secures superior rigidity by applying wedge type Y-axis

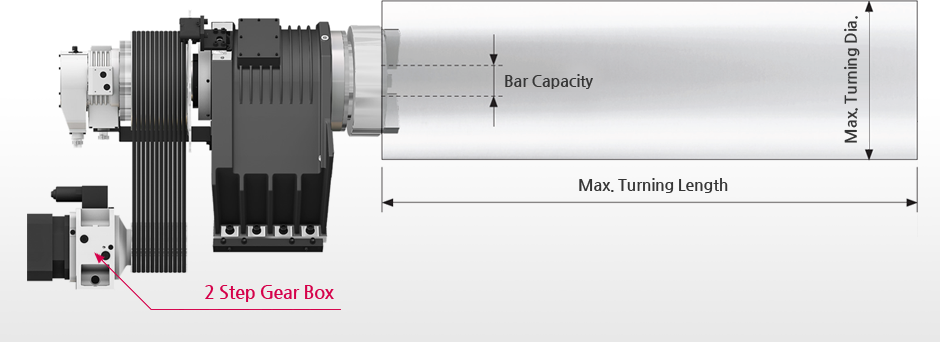

- Specialized in heavy cutting by applying 2 Step Gear Box Type Main Spindle (Max. Torque 2,990 N·m)

- Secures rigidity with box guideways for each shaft

- Max. Turning Length 2,070 mm Long Bed Structure

- High-performance Large BMT75 Turret

Y-axis Machining

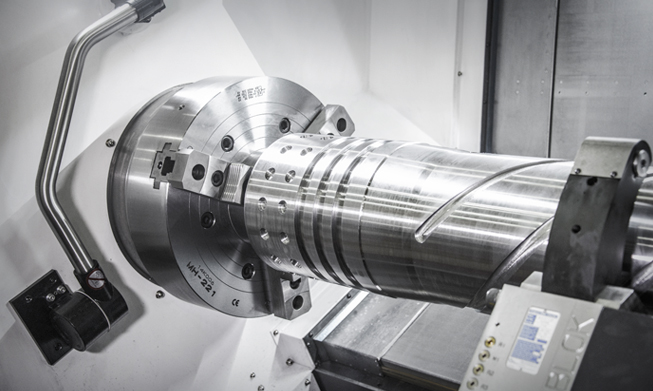

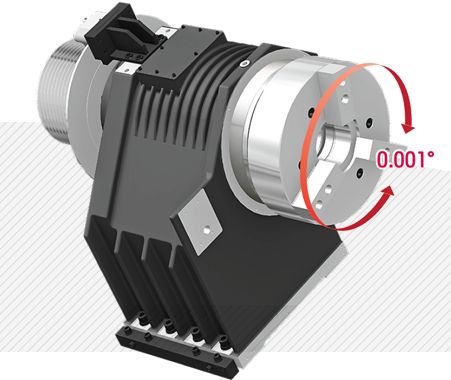

Secures superior rigidity by applying wedge type Y-axis

1Y-axis Machining

Wedge Type Y-axis Structure

Designed with a compensating Y-axis structure that is fed by the simultaneous operation of the YS-axis and the X-axis, L5100LY features a tool rest of superior rigidity which demonstrates excellent performance for heavy-duty product machining. In particular, off-center machining is available, which is not possible with general lathes, so that high added value products can be manufactured without additional post-processing.

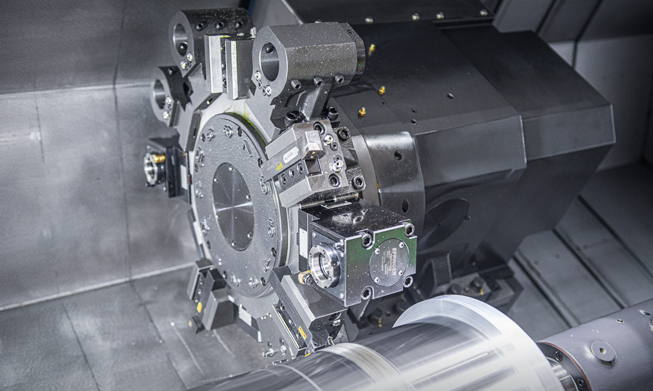

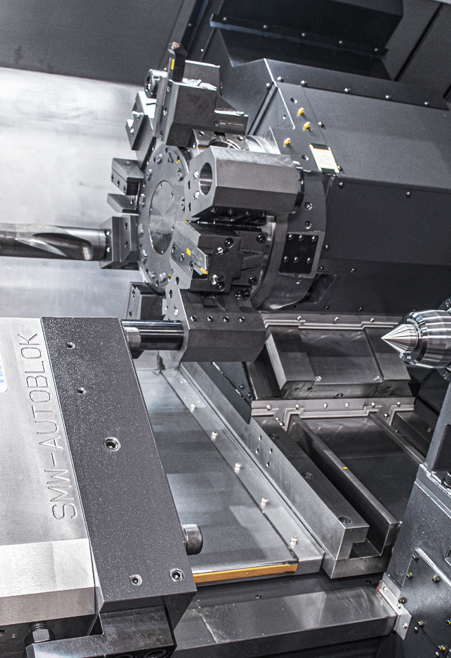

BMT75 Turret

The large 12-station large BMT turret enables the L5100LY to perform high accuracy milling operations in a single setup.

As an option, a 24-angle turret can be applied to increase the tooling range.

- 12 angles

Rotation of 30 degrees per side - 24 angles

Rotation of 15 degrees per side

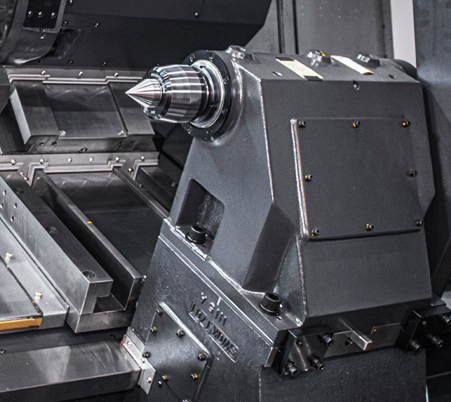

Increased Tool Rest Rigidity

Unlike other holders, the internal holder features a structure which stabilizes two more shafts along the Z-axis, and rigidity along the Z-axis is increased by 5% compared to the previous model.

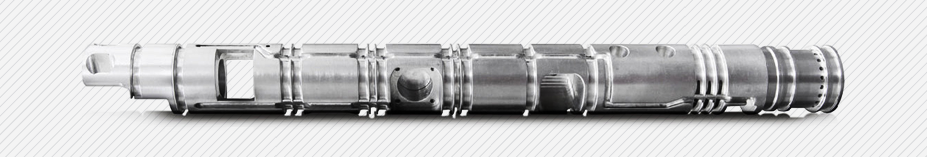

Machining Sample