New Product

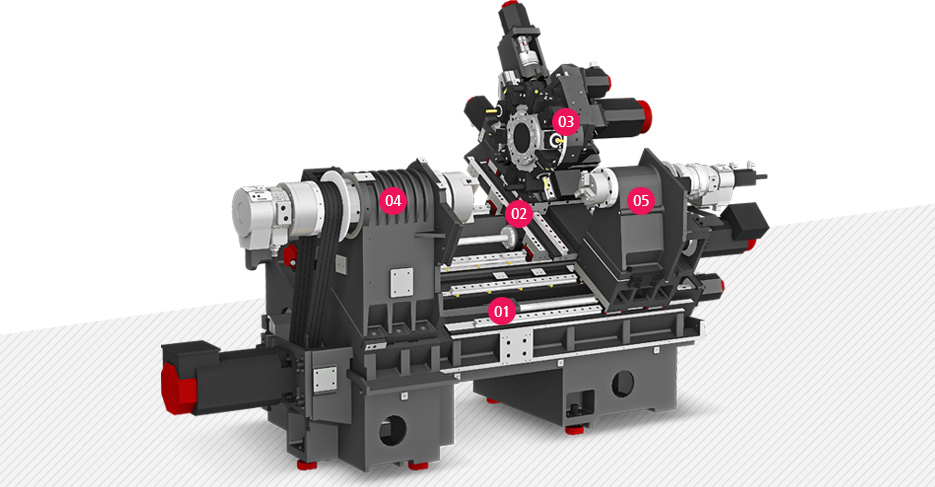

SE-SY Series Versatile, High Production Y-Axis CNC Turning Center

Hyundai WIA, one of the largest machine tool makers in Korea, used its accumulated know-how and latest technology to develop the SE-SY Series, which delivers high-performance, high heavy cutting capability, and maximum productivity concurrently.

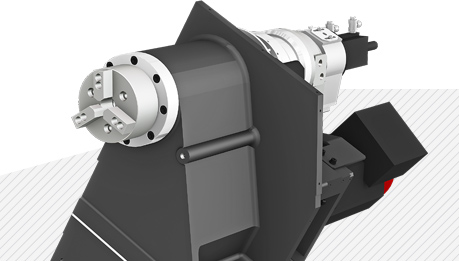

Y-axis CNC Turning Center specialized in small-parts

- 30° slanted one-piece bed structure with high rigidity

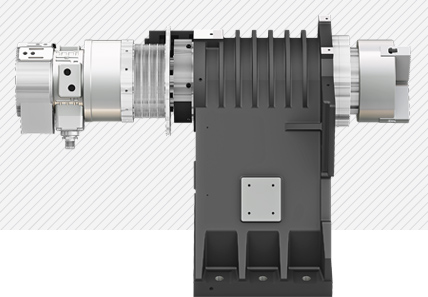

- Stabilized unit structure to minimize thermal displacement

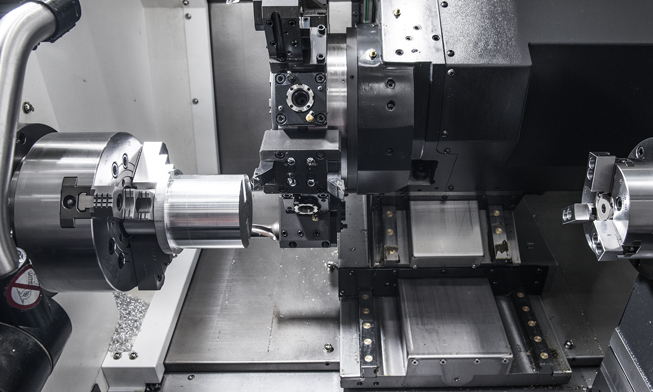

- Integrated processing through synchronized control of Main/Sub spindle

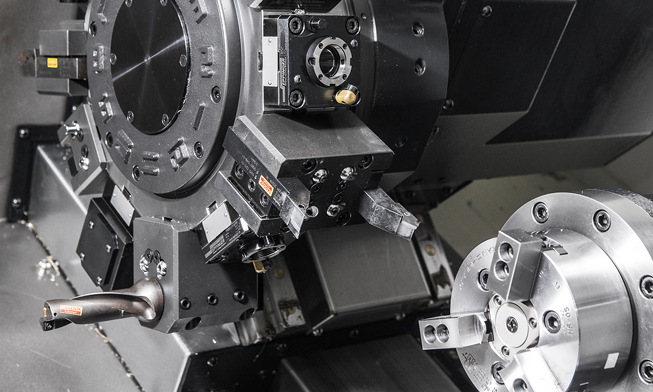

- Multi-tasking operation with wedge type Y-axis BMT45P turret

- Ergonomic design for convenient access to chuck and tool

- Latest FANUC 0i PLUS Controller (15” touch screen)

Basic Features

CNC Lathe with Y-axis, which can process ALL through single setting

1Optimal Structural Analysis

Structural analysis was applied to the design of the machine to increase the tool post body and reduce the machine’s height so as to maintain the bed’s dynamic rigidity even during heavy-duty cutting.

In addition, the SE-SY Series bed slope is pitched at 30 degrees to ensure more stable machining.

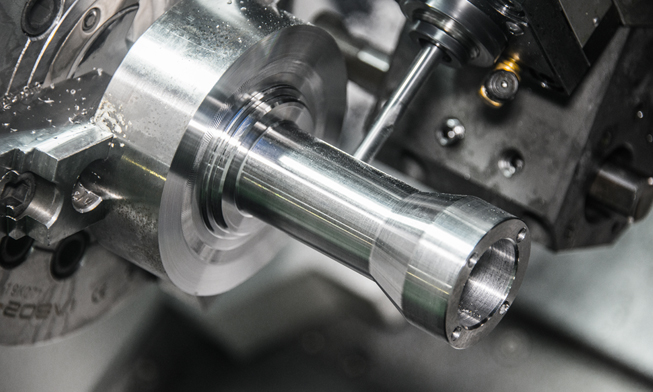

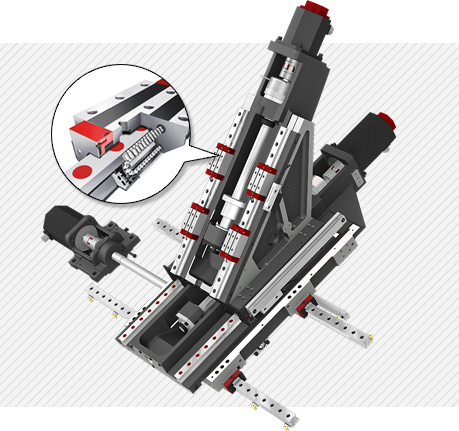

2High-speed Roller LM Guideway

Linear roller guideways are applied in SE-SY Series to reduce non-cutting time and bring high-rigidity.

In order to eliminate thermal growth and increase accuracy, all axes are driven by high precision double anchored ballscrews.

| Rapid Traverse Rate (X/Y/Z/ZB) | 30/10/36/15 m/min (1,181/394/1,417/591 ipm) |

| Travel Distance (X/Y/Z/ZB) | 210/110/560/560 mm (8.3"/4.3"/22"/22") |

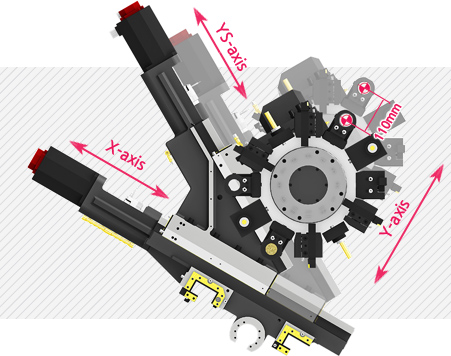

3Wedge Type Y-axis Structure

The SE-SY Series is designed with a wedge type Y-axis that is transferred by the simultaneous operation of the Ys-axis and the X-axis. In addtion, excellent rigidity makes possible to perform superb quality when machining a heavy-duty cutting.

| Y-axis Rapids | 10 m/min (394 ipm) |

| Y-axis Travel Range | 110 (±55) mm (4.3"(±2.2")) |